The Top Steel Pipe Manufacturers in Saudi Arabia

Release time:

2026-01-12

I.market profile

1.1 Market Size and Growth Trend

- The market size of Saudi steel pipes will reach 507 million US dollars in 2024, and is expected to increase to 582.3 million US dollars by 2033, with a compound annual growth rate (CAGR) of 1.50%

- The market value of spiral welded pipes in 2024 is approximately 1.9 billion US dollars, dominating the Middle East region

- Key growth drivers: Infrastructure investment under Saudi's "Vision 2030", expansion of the oil and gas industry, seawater desalination projects, and development of new energy sources

1.2 Market Structure and Application Areas

| Product Type | Main Application | Market Share |

| Seamless Steel Pipe | Petroleum and natural gas (oil well pipes, transportation pipes), high-pressure chemical industry | About 30% |

| ERW Welded Pipe | Construction, industrial pipelines, oil and gas transportatio | About 40% |

| LSAW/Coiled Wire Welded Pipe | large-scale water diversion projects | About 25% |

| Stainless steel/alloy pipe | Chemical industry, seawater desalination, hydrogen energy projects | About 5% |

- Key demand industries: Oil and gas (45%), Infrastructure construction (30%), Water treatment (15%), Petrochemicals (10%)

- Regional distribution: The eastern regions (Dammam, Jubbayl) are the main production and consumption areas, Riyadh is the central market, and Jeddah is the logistics hub along the Red Sea coastline.

1.3 Policy and Market Characteristics

- Since June 2025, a 24.6% anti-dumping tax has been imposed on Chinese stainless steel pipes, and 27.3% for Taiwan regions.

- Import Control: All steel pipes must obtain PCoC (Product Conformity Certificate) and SCoC (Shipping Conformity Certificate) through the SABER system, in accordance with the SASO standards.

- Localization Trend: The government encourages local production. In 2025, three new 200,000-ton per year spiral welded pipe factories were added in Jubail.

II. Ranking of Major Steel Pipe Manufacturers and Detailed Information

2.1 Local Leading Enterprises

1. East Pipes Integrated Company for Industry (1321.TADAWUL)

- Market Position: The largest manufacturer of spiral submerged arc welded pipes (HSAW) in Saudi Arabia. Established in the Second Industrial City of Dammam in 2010.

- Production Capacity: Annual production of 5 million tons of steel pipes, coating capacity of 4.5 million square meters per year.

- Core Products: Spiral submerged arc welded pipes with a wide range of diameters, used for oil and gas transportation and large-scale water transmission projects.

- Customers: Saudi Aramco (with a contract worth 480 million US dollars), SWCC (Saudi Desalination Company), etc.

2. Arabian Pipes Company (2200.TADAWUL)

- Establishment Date: 1991, Headquarter in Riyadh, Branch Factory in Jubail

- Total Production Capacity: Annual output of 460,000 tons (160,000 tons in Riyadh ERW + 300,000 tons in Jubail LSAW)

- Core Products: ERW (6-20 inches) and LSAW (16-48 inches) welded pipes, API certified, used in oil and gas and structural engineering

- Advantages: Main supplier of LSAW welded pipes in the Middle East region, exported to North Africa, the Middle East and Gulf countries

3. TenarisSaudiSteelPipes (formerly Saudi Steel Pipe Company)

- Market Position: A pioneer in the Saudi steel pipe industry, jointly established with Tenaris

- Core Products: ERW steel pipes (black pipes, galvanized pipes), oil well pipes (OCTG), API standard pipeline pipes

- Application Fields: Energy (oil and gas), industrial and construction sectors, providing complete pipeline solutions

4. JESCO (Jubail Energy Services Company)

- Establishment Date: 2006, owned by TAQA Group (51% stake)

- Unique Position: The first seamless steel pipe manufacturer in the Gulf region, filling the gap in the local market

- Products: Seamless steel pipes, mainly serving the oil and gas industry, in compliance with API 5CT standards

5. Al-Jazera Factories For Steel Products (JASCO)

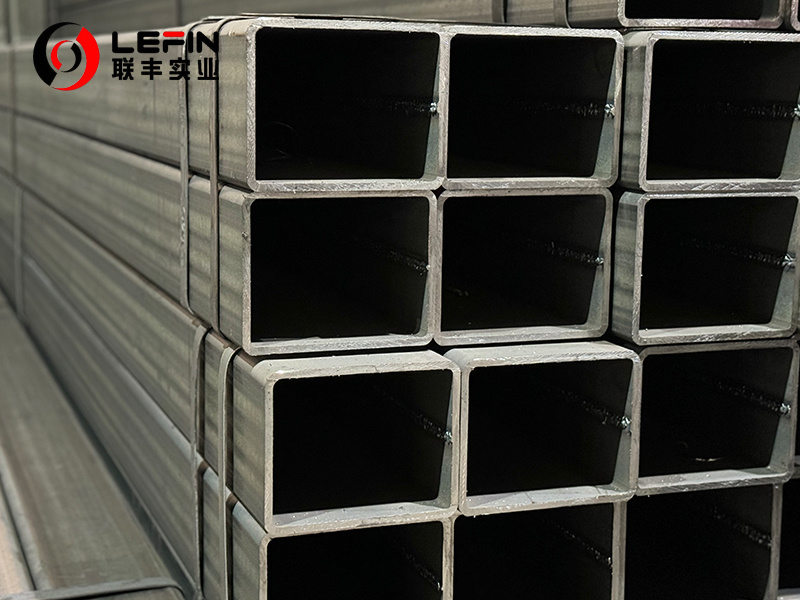

Saudi Arabia's leading comprehensive steel pipe manufacturer, whose products include welded steel pipes and square/rectangular tubes, are applied in construction and infrastructure.

2.2 Other Key Manufacturers

- Group Five Pipe Saudi: The largest manufacturer of large-diameter HSAW pipes in the Middle East, with diameters ranging from 20 to 120 inches and thickness starting from 6.35 mm.

- Alcatini-PCK: A joint venture between the Alcatini Group and a Chinese enterprise, specializing in the production of straight seam welded pipes.

- Aasia Steel Factory (ASFC): A producer of composite steel products, providing composite steel pipes for the oil and gas industry.

- Gerab National Enterprises: A large-scale steel pipe supplier, with inventory covering carbon steel pipes, stainless steel pipes, duplex steel, etc., in sizes ranging from 1/4" to 120".

III. Manufacturer Selection Suggestions

3.1 Core Evaluation Dimension

| Evaluation Criteria | Key Considerations | Selection Points |

| Qualifications | API, ISO9001/14001, SASO, Saudi Aramco Standard (SAMSS) | Preferentially choose enterprises that have both API 5L (pipeline pipe) and API 5CT (oil well pipe) certifications |

| Production Capacity and Delivery | Annual production capacity, order delivery cycle, inventory level | For large projects, choose enterprises with a production capacity of ≥ 300,000 tons per year to ensure timely delivery |

| Technical Capability | Production process (ERW/LSAW/Coil Welding), testing equipment | For oil and gas high-pressure projects, prefer seamless pipe or LSAW welded pipe manufacturers |

| Industry Experience | Establishment time, main customers, project case | Preferentially choose enterprises with cooperation experience with large clients such as Saudi Aramco and SWCC |

| Local Services | Local factory, after-sales service, technical support | For long project cycles, it is recommended to choose manufacturers with local factories to reduce logistics and communication costs |

3.2 Select the manufacturer based on the application scenario

1. Oil and Gas Industry

- Preferred: TenarisSaudiSteelPipes, JESCO (welded pipes), Arabian Pipes (LSAW)

- Reasons: Comply with API standards, have long-term cooperation experience with Saudi Aramco, and have strict quality control.

2. Large-scale water transmission/seawater desalination

- Preferred options: East Pipes (welded spiral pipe), Group Five Pipe (large diameter)

- Reasons: Welded spiral pipe is suitable for long-distance transportation and has mature corrosion-resistant coating technology

3. Construction and Infrastructure

- Preferred: Arabian Pipes (ERW), JASCO, Saudi Steel Pipe

- Reasons: ERW pipes offer high cost-effectiveness and are suitable for structural pipes and ordinary water transmission systems.

4. Chemical/High Pressure Applications

- Preferred: JESCO (Seamless Tube), Aasia Steel (Composite Tube)

- Reasons: Seamless tubes can withstand high pressure and high temperature, while composite tubes are suitable for corrosive media.

IV. Procurement Skills and Practical Guidelines

4.1 Essential Knowledge on Compliance and Certification

1. SABER Certification Process

- Apply for a 1-year valid PC certificate (product conformity certificate) at a cost of $500 - $3000

- Apply for SC certificate (shipment conformity certificate) for each batch of goods, which must be completed before the goods arrive

- Certification period: standard 8-12 weeks. For expedited service (double the cost), it can be shortened to 10 working days

2. Quality standard verification

- The steel must meet the anti-corrosion standard of SASO 2694 and provide a chemical composition analysis report

- Oil and gas pipes must comply with API 5L/5CT, and building pipes must meet international standards such as ASTM A53

- The product labels must indicate the SASO logo, specification model, and production batch number

4.2 Price and Negotiation Strategy

1. Cost Composition Analysis

- Raw materials (steel billets) account for approximately 60-70%, transportation 10-15%, manufacturing costs 10-15%, and profit 5-10%

- Note: Starting from 2025, the import tax for stainless steel pipes in China will reach as high as 24.6%, which will affect the procurement cost

2. Negotiation Points

- Bulk Purchase: A 5-10% price discount can be obtained for orders over 1000 tons

- Long-term Agreement: Sign a contract of 6-12 months to lock in the price and avoid risks from fluctuations in raw materials

- Payment Terms: Strive for a 30-60 day payment period to reduce capital costs

- Localized Cooperation: Form a joint venture or engage in technical cooperation with local manufacturers, which can lead to government incentives

4.3 Quality Control and Acceptance Process

1. Sampling Inspection

- Randomly select 3-5% of the samples from each batch to check for dimensional accuracy, uniformity of wall thickness, and surface quality

- Conduct water pressure tests (in accordance with API standards: 1.5 times the working pressure) and non-destructive testing (ultrasonic/eddy current)

2. Document Review

- Required Documents: Certificate of Origin, SASO Certification, API Certificate, Quality Inspection Report, Packing List

- Note: All documents must be in both Arabic and English and must be notarized.

4.4 Logistics and Supply Chain Optimization

1. Transportation Options

- Local Procurement: Preferentially select the factories in the east (Dammam/Jubail) to reduce inland transportation costs

- Import Procurement: Enter through Jeddah Port or Dammam Port, which offers higher clearance efficiency

2. Inventory Management

- For large projects, it is recommended to establish a local warehouse to store common specifications, thereby shortening the construction period.

- Negotiate with suppliers for JIT (Just-In-Time) delivery to reduce storage costs.

V. Risk Mitigation and Best Practices

1. Market Risk

- Price Fluctuation: Include price adjustment clauses with suppliers, based on the steel billet market index

- Policy Changes: Keep a close eye on the latest regulations of the Saudi Standards and Metrology Organization (SASO) and the customs, and adjust strategies in advance

2. Quality Risks

- Third-party testing: Entrust international institutions such as SGS and BV to conduct independent quality verification

- Contract terms: Clearly define the compensation mechanism for quality non-compliance, including returns, exchanges, and fines

3. Delivery Risks

- Multi-source Supply: Select 2-3 suppliers for critical projects to avoid disruption from a single source

- Progress Tracking: Establish a weekly progress reporting mechanism to promptly address production or logistics issues.

Summary

The Saudi steel pipe market is currently experiencing a period of stable growth. Domestic manufacturers are continuously improving their technologies and production capacity, which can now meet most of the domestic demand. When choosing a manufacturer, one should consider the project type, technical requirements and budget, and give priority to enterprises with complete qualifications, rich experience and local service capabilities. During the procurement process, strictly adhering to the Saudi SABER certification requirements, paying attention to quality control and contract terms, can effectively reduce risks and ensure the smooth progress of the project.

Tags:

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn