BLACK PIPE VS GI PIPE

Release time:

2024-09-23

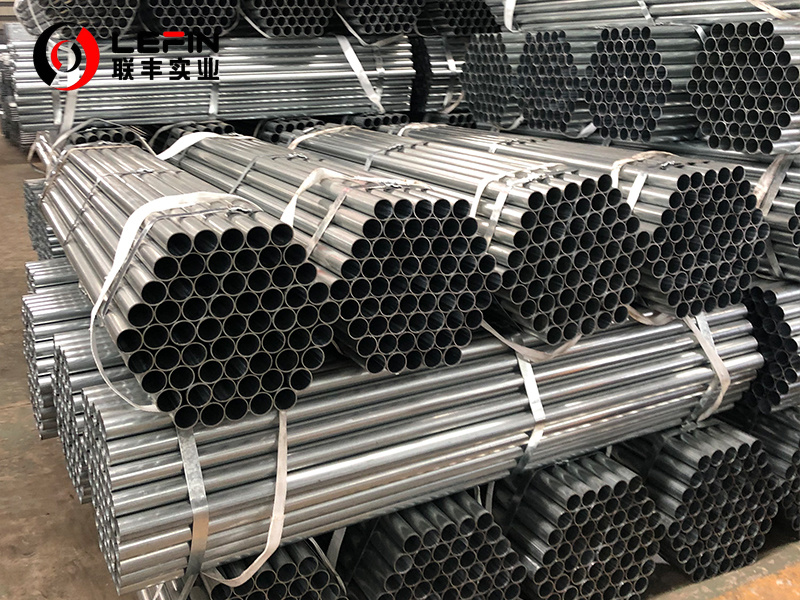

Black pipe and galvanized(GI) pipe are two common pipe types. Black pipe, also known as steel pipe, is made of carbon steel with a dark iron oxide coating on the surface. GI pipe, also known as galvanized iron pipe, is made of steel coated with zinc to prevent rust and corrosion. LEFIN STEEL can produces both black pipe and GI pipe.

BLACK PIPE VS GI PIPE

Black pipe and galvanized(GI) pipe are two common pipe types. Black pipe, also known as steel pipe, is made of carbon steel with a dark iron oxide coating on the surface. GI pipe, also known as galvanized iron pipe, is made of steel coated with zinc to prevent rust and corrosion. LEFIN STEEL can produces both black pipe and GI pipe.

Contact: Nina Wang

Whatsapp: 008618892236531(whatsapp)

Email: nina@lefinsteel.com

Black pipes:

Processing process:

1. The first step is high-quality raw materials such as carbon steel. Generally speaking, the raw material of clarinet is carbon steel.

2. Test purchased carbon steel for strength, flexibility and durability.

3. Use cutting and shaping tools to cut and shape the material to the desired size.

4. Use high-intensity heat to weld the cut and formed pipes together.

5. The pipe undergoes a surface treatment process to remove any impurities or surface defects that may affect its performance.

6. Coat the pipes with a layer of black paint to give them their characteristic black color.

7. The pipe is cut to the required length and packaged

Application:

1. The black tube is made of carbon steel, which is strong and durable and very suitable for industrial applications. Black pipe is used in a variety of industries, including oil and gas, pipelines and construction.

2. Black pipes are mostly used in construction projects

3. The corrosion-resistant characteristics make black pipes an ideal choice for transporting materials and liquids under extreme conditions.

Advantage:

1. The black pipe is made of carbon steel, which is strong and durable and can withstand high temperature and pressure. It is an ideal choice for transporting materials and liquids under extreme conditions.

2. One of the benefits of using black pipes is that they are easy to install, saving valuable time and resources. They are also cost-effective, which is crucial in large-scale construction projects.

3. Another advantage of black pipes is that they are corrosion-resistant and are very suitable for use in humid environments.

GI pipe:

Processing process:

1. The first step in the GI PIPE processing process is to select high-quality raw materials. Generally, the raw material of GI PIPE is low carbon steel.

2. Perform various stages of processing on the pipeline including cleaning, pre-treatment and coating.

3. After cleaning, use a pretreatment solution on the pipe to help improve the adhesion of the galvanized layer on the pipe surface.

4. Use hot-dip galvanizing or electroplating to immerse the pipe in a molten zinc bath and coat the surface with zinc evenly.

5. Conduct quality checks on pipes and conduct strength and durability tests.

6. The pipe is then cut to the required length and shape, ready for various applications.

Advantage:

1. The use of GI tubes not only brings a lot of convenience, but also has little impact on the environment.

2. The zinc layer of GI pipes has an anti-corrosion effect and can be reused. With proper maintenance of the pipes, it can be used for decades, reducing corporate expenses.

3. In addition, scaffolding also has GI pipes. They are very light and easy to carry.

Application:

1. GI PIPE has a wide range of applications. GI pipes can be used in construction, agriculture, and industry.

2. GI pipe is the main material for some important projects, such as large buildings, oil and gas pipelines, bridges and underground pipelines.

3. Therefore, these pipes are widely used in modern society.

Differences between Black pipe and GI pipe:

1. Processing process differences. Black pipes are coated with black paint or immersed in a chemical bath containing a blackening agent to form an iron oxide film. Galvanized pipes are processed by immersing steel pipes in zinc liquid.

2. Black pipe is cheaper than GI pipe as the zinc coating adds to the cost. GI pipe use the hot dip galvanized processing, it made the price higher than Black pipe. The purchase cost is reduced, but the durability and service life of GI pipes are better than those of black pipes.

3. Application differences. Galvanized pipes are usually used for water transportation, and black steel pipes are used for gas transportation.

Black pipe and galvanized pipe are both widely used, but there are many differences. You can choose products according to your needs.

Tags:

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn