What Are The Production Types Of Steel Pipes

Release time:

2025-10-22

The production types of steel pipes are diverse and can be classified in various ways such as production process, material, cross-sectional shape and application. Among them, the most core and fundamental classification basis is the production process, which directly determines the basic characteristics of steel pipes.

The following table can help you quickly understand the main classification methods and their specific types.

| Classification standard | Main type | Core features/Examples of subclasses |

| 🏭Manufacturing technique | Seamless Pipe | It is made by piercing solid tube billets, has no welds and strong pressure-bearing capacity |

| Welded Steel Tube | It is made by rolling and welding steel plates or steel strips, featuring high production efficiency and relatively low cost. For example: straight seam welded pipe, spiral welded pipe | |

| 🧩 section shape | Round Steel Pipe | The most common shape, the main force used for fluid transportation and structure |

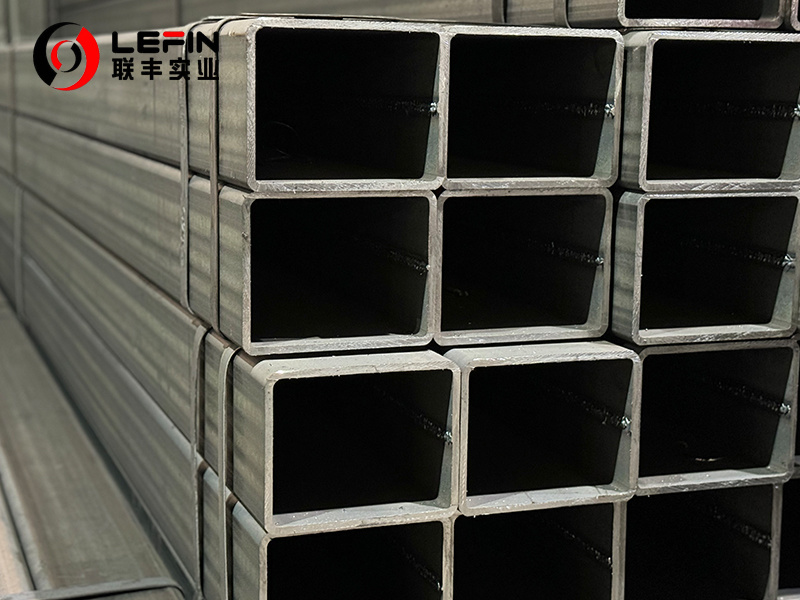

| Special-shaped | With non-circular cross-sections, such as square, rectangular, and elliptical ones, are mostly used in specific structural components. | |

| 🛡️ Material | Carbon Steel Tubing | Common carbon structural steel, high-quality carbon structural steel |

Alloy-steel Tube | Low alloy structural steel, alloy steel, etc., possess better mechanical or special properties (such as heat resistance and corrosion resistance) | |

| Stainless Steel Tube | Outstanding corrosion resistance, used in the fields of chemical engineering, food, medical care, etc | |

| 🎯 application | Line Pipe For Pipeline | Transport fluids such as water, oil, gas and coal. |

| Mechanical Tube | Building grid structures, pillars, mechanical components, etc | |

| Special Pipe | Meet specific environmental requirements, such as boiler tubes, geological drilling tubes, oil casing, etc |

💡 How to distinguish and choose

• Check the weld seam:

Welded steel pipes usually have weld seam marks, while seamless steel pipes do not. This is one of the most intuitive ways to distinguish.

• Clear purpose:

Select based on the key requirements of the usage scenario. For instance, seamless steel pipes should be given priority in situations involving high pressure, high temperature or severe impact (such as high-pressure boilers and hydraulic systems). For low-pressure fluid transportation or general structural support (such as building scaffolding and ventilation ducts), economical and practical welded steel pipes are often a more suitable choice.

• Check standards:

All types of steel pipes have corresponding national (GB) or industry standards, which clearly stipulate their dimensions, materials, performance indicators and applications. This is an important basis for ensuring the selection of the right pipe materials.

Tags:

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn