What are the differences between hot dip galvanized and cold galvanized?

Release time:

2024-09-13

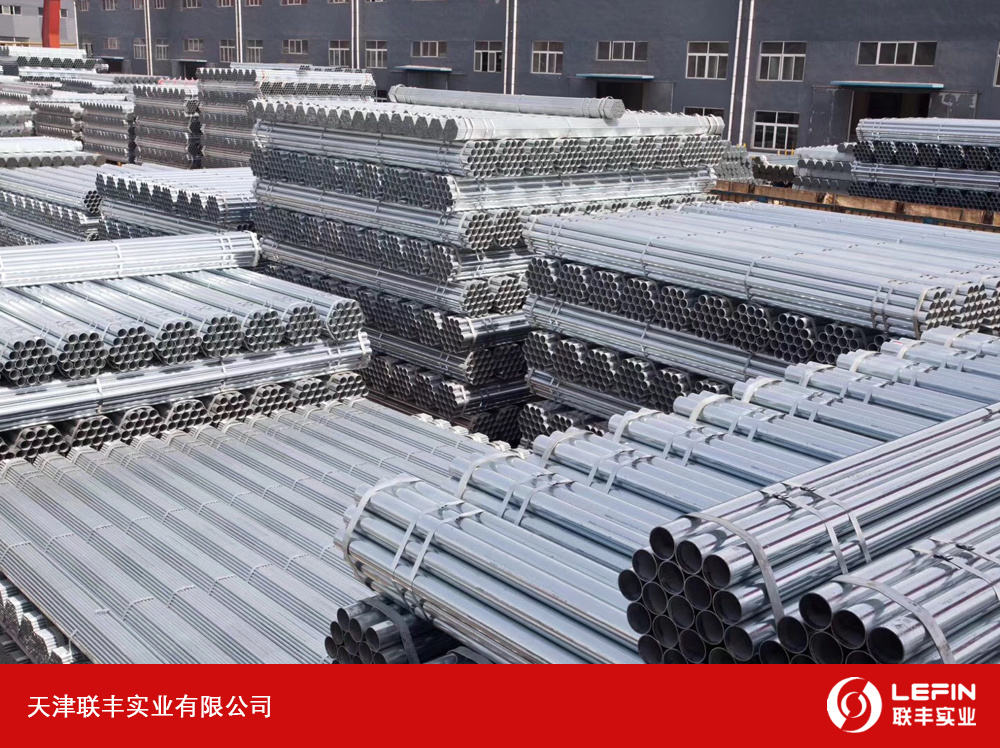

Galvanizing is a common anti-corrosion method and is often used in steel pipe processing. Hot-dip galvanizing and cold-dip galvanizing are both anti-corrosion coatings for steel, both methods have their pros and cons, but both are designed to increase the life and durability of the steel. LEFIN STEEL can do the two processes.

What are the differences between hot dip galvanized and cold galvanized?

Galvanizing is a common anti-corrosion method and is often used in steel pipe processing. Hot-dip galvanizing and cold-dip galvanizing are both anti-corrosion coatings for steel, both methods have their pros and cons, but both are designed to increase the life and durability of the steel. LEFIN STEEL can do the two processes.

Contact: Nina Wang

Whatsapp: 008618892236531

Email: nina@lefinsteel.com

Hot dip galvanizing:

Generally speaking, hot dip galvanizing is the most common galvanizing method.

Zinc layer thickness: Generally, the minimum thickness of the zinc layer should be at least 80 μm, according to industry standards.

Manufacturing processes:

1. First clean the steel surface thoroughly to remove any dirt or other impurities.

2. The steel is immersed in hot-melt zinc, usually at a temperature of about 450 degrees Celsius.

3. Wait for a thick and even zinc coating to form on the surface of the steel.

4. When steel is immersed in zinc, a chemical reaction occurs and these intermetallic compound layers are tightly bonded to the steel surface, providing excellent corrosion resistance.

Advantages:

1. Hot dip galvanizing provides excellent corrosion resistance to steel or iron parts.

2. Hot-dip galvanized coatings can last up to 50 years in most environments, making them ideal for applications that require a long-lasting, durable coating.

3. Hot-dip galvanized components require minimal maintenance. The zinc coating is self-healing, meaning that even if it gets scratched, the exposed area will still be protected.

4. Although the initial cost of galvanizing is higher than other coatings, it is cost-effective in the long run. Reduce costs by eliminating maintenance costs, repairs and replacements.

5. Environmental protection: Hot-dip galvanizing is a green process and does not produce hazardous waste. The zinc in galvanized coatings is easily recycled, making it an environmentally friendly choice.

Application:

1. Hot-dip galvanizing is suitable for everyday items such as building structures to fences and gates. This technology is used in environments where metal is often exposed to harsh conditions such as moisture, salt water or acidic chemicals.

2. Hot-dip galvanizing technology is used to protect structural steel used in the framing of buildings, bridges, and other infrastructure projects. Galvanized steel provides long-term corrosion protection

3. Hot-dip galvanizing can be used on outdoor products such as furniture, fences, and gates. These items are often exposed to the elements year-round, and hot-dip galvanizing ensures they remain rust-free.

3. Hot-dip galvanized steel can also be used in the automotive industry and is often used as a protective coating for automotive parts to prevent corrosion.

Cold galvanized:

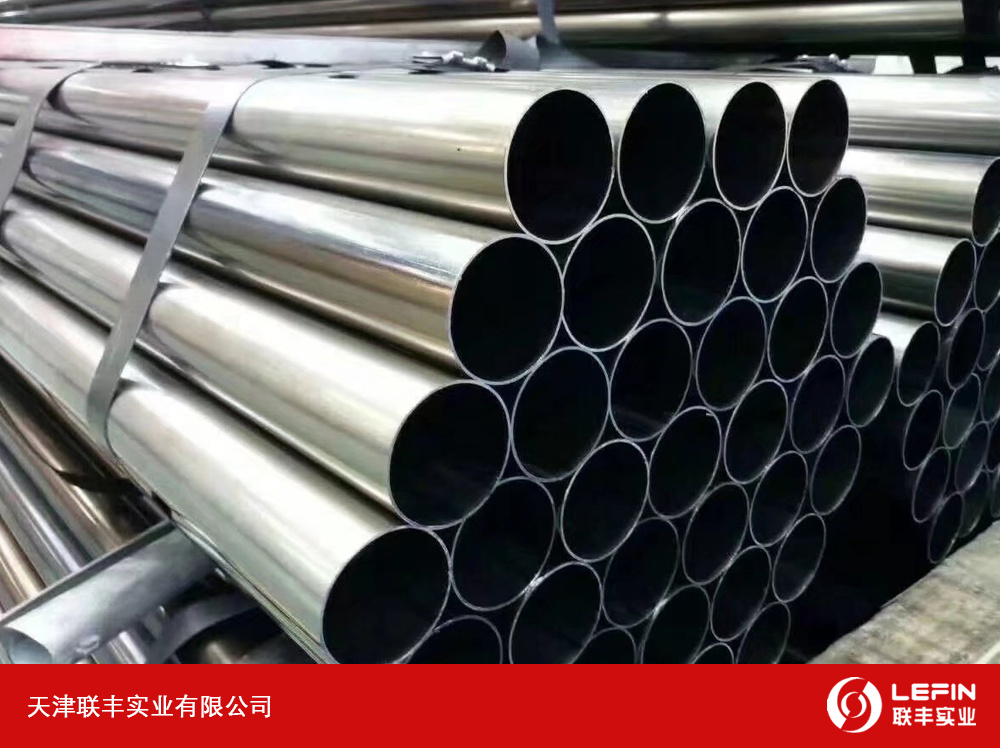

Cold galvanizing is a good option when the steel product cannot be immersed in a molten zinc bath.

Zinc layer thickness: Cold galvanizing is an electroplating process that provides only a thin coating of zinc, typically around 5-15 microns

Manufacturing processes:

1. Steel pipe surfaces should be thoroughly cleaned and degreased to remove any dirt, oil, grease or other contaminants that may hinder coating adhesion.

2. Prime the surface with a low-viscosity resin to promote adhesion of the zinc-rich coating.

3. After applying the primer, let it dry.

4. Use a spray gun, brush or roller to complete the coating

Advantages:

1. Cold galvanizing is cheaper than hot dip galvanizing due to its simple workmanship and thin zinc layer.

2. Cold galvanizing is easy to process and can be completed on site. The process involves spraying or brushing a zinc-rich coating onto the steel surface. It dries quickly and provides instant protection.

3. Cold galvanized coating is long-lasting and can provide protection for up to 10 years or more, depending on environment and conditions.

4. Cold galvanizing helps protect the steel surface from corrosion. Resists moisture and prevents rust and other forms of corrosion.

5. Cold galvanizing provides uniform coverage and can be applied to complex shapes and hard-to-reach areas.

6. Cold galvanizing does not use harmful chemicals or gases and has less impact on the environment.

Application:

This method can be used when the steel member cannot be hot-dip galvanized due to its size, shape or other limitations. However, it is not as durable as the thick coating produced by hot-dip galvanizing.

1. Cold galvanizing can extend the service life of metal surfaces. Zinc-rich paint forms a protective layer on the surface, protecting it from exposure to corrosive elements.

2. Cold galvanizing can be applied to a variety of metal surfaces, including steel, aluminum and iron. It is commonly used in industrial settings such as oil rigs and pipelines, as well as residential settings

Differences:

1. Hot-dip galvanizing coating does not have the same amount as cold-dip galvanizing. If you are looking for beauty, you can choose cold-dip galvanizing.

2. Hot-dip galvanizing Hot-dip galvanizing is a more expensive process due to its higher temperatures and the need for specialized equipment and facilities. Cold galvanizing, on the other hand, is a more affordable process due to its simplicity and ease of use. The price of cold galvanizing is lower than that of hot dip galvanizing.

3. Hot-dip galvanizing produces a thicker, more durable coating and is recommended for larger components and structures, while cold-dip galvanizing is suitable for smaller components or components that cannot be hot-dip galvanized.

4. Cold galvanizing is much cheaper than using the traditional hot dip galvanizing method, which involves immersing metal objects in molten zinc. Cold galvanizing can be easily applied on site and requires no specialized equipment or facilities.

Which one is better:

Both hot-dip galvanizing and cold-dip galvanizing have their own advantages.

Hot-dip galvanizing provides a durable and strong coating that can withstand long-term exposure to harsh environments.

Although cold-dip galvanizing coating is thinner and less durable than hot-dip galvanizing, it still provides adequate protection against rust and corrosion and is often used in small products.

Generally speaking, although hot-dip galvanizing and cold-dip galvanizing are both anti-corrosion galvanizing, they are different. Customers can choose the galvanizing method according to the use environment, cost and zinc layer requirements. It's important to consult with a trusted galvanizing professional to determine the best solution for your product.

Tags:

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn