- Details

-

Basic Information

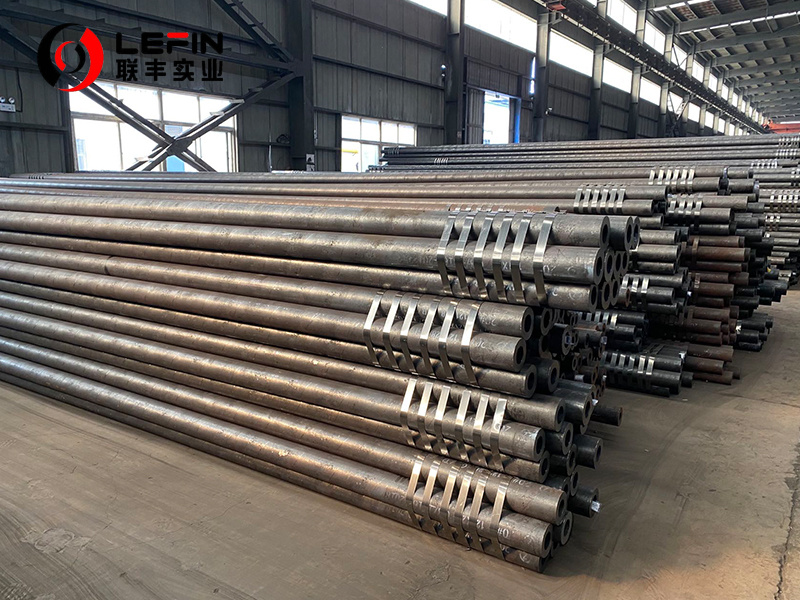

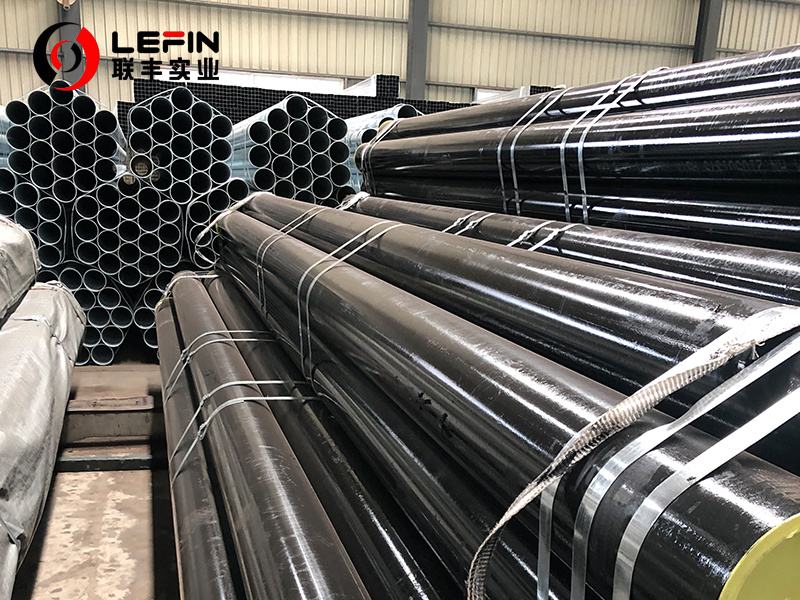

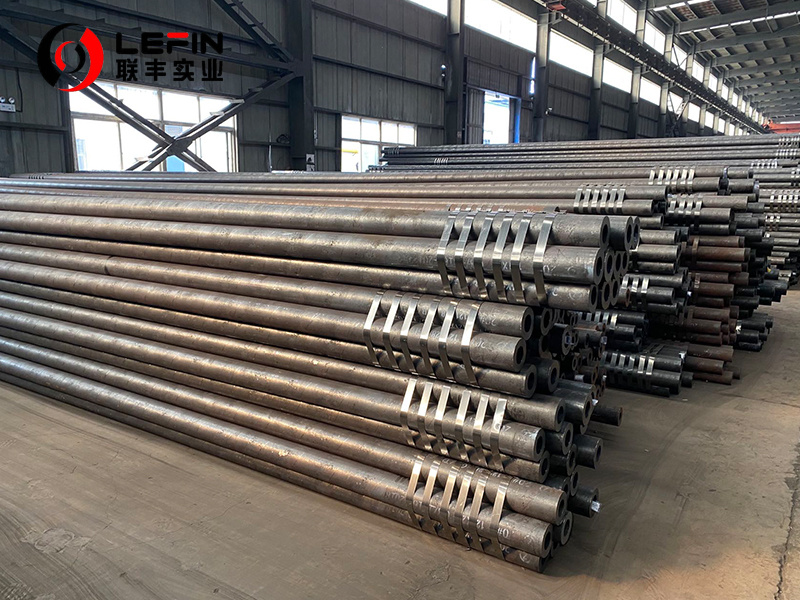

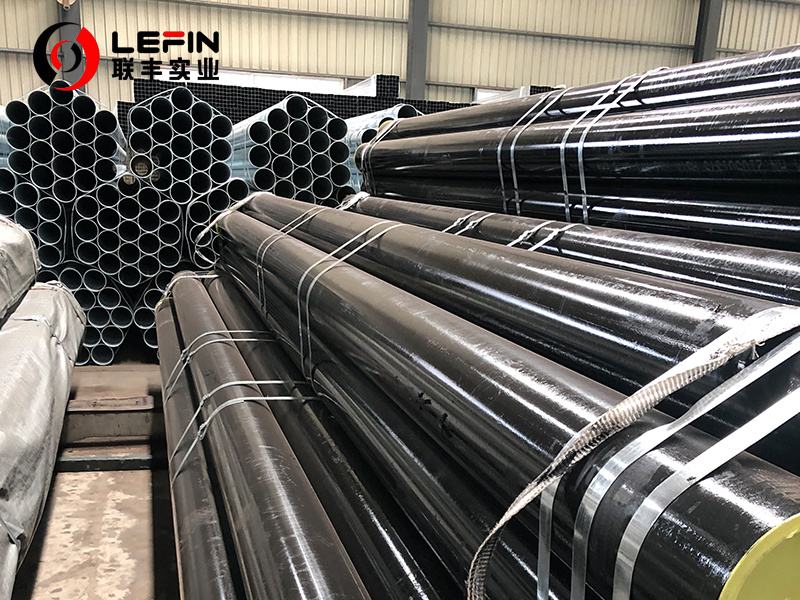

API 5L GR.B is a specification standard for steel pipes used in transmission pipeline systems. These pipes are designed to transport natural gas, petroleum, and other fluids in the oil and gas industry.API5L GR.B PIPE

Grades: GR.A, GR.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Wall Thickness Range: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Manufacture Types: Both seamless and welded (ERW and LSAW).

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Bare, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP,.CWC (Concrete Weight Coated) CRA Clad or Lined.

Chemical Composition● Carbon (C): Maximum 0.28%

● Manganese (Mn): Maximum 1.20%

● Phosphorus (P): Maximum 0.030%

● Sulfur (S): Maximum 0.030%

● Silicon (Si): Maximum 0.40%

Carbon (C): Carbon is a critical element that enhances the strength and hardness of the steel. However, too much carbon can reduce ductility and weldability. The controlled carbon content in Grade B pipes ensures a balance between strength and weldability.

Manganese (Mn): Manganese acts as a deoxidizer, removing dissolved oxygen from the molten steel, which helps prevent inclusions that can weaken the steel. It also increases the yield strength and tensile strength of the pipe.

Phosphorus (P) and Sulfur (S): Phosphorus and sulfur can have detrimental effects on the steel's properties. High levels of phosphorus can lead to brittleness and cracking, while sulfur can cause hot cracking during welding and hydrogen-induced cracking. Strict limits ensure the pipe remains ductile and weldable.

Silicon (Si): Silicon improves deoxidation and desulfurization properties, enhancing weldability and corrosion resistance. It also promotes the formation of a protective oxide layer on the steel's surface.

Mechanical Properties

● Tensile Strength: Minimum 415 MPa

● Yield Strength: Minimum 245 MPa

● Elongation: Typically around 23%, depending on pipe thickness.

This makes them suitable for a wide range of applications, including high-pressure and corrosive environments. The moderate strength ensures that the pipes can withstand the demands of transporting oil, natural gas, and other fluids without being overly expensive or difficult to fabricate .

Applications And AdvantagesApplications

● Transmission Pipelines: Transporting crude oil, natural gas, and other petroleum products from production sources to processing locations.

● Distribution Pipelines: Distributing refined products such as gasoline and diesel to distribution terminals.

● Subsea Pipelines: Used in offshore installations to transfer oil and gas from the seabed to the surface.Advantages

● High Strength: API 5L GR.B pipes have high tensile and yield strengths, making them suitable for high-pressure applications.

● Good Weldability: The controlled carbon content ensures good weldability, which is crucial for pipeline construction.

● Corrosion Resistance: The pipes are designed to withstand corrosive environments, ensuring long service life.

● Reliability: Strict manufacturing processes and quality control ensure high reliability and consistency in performance.

Why Is API 5L Grade B A Relatively Commonly Used Line Pipe In The API 5L Series?

API 5L Grade B is the most commonly used line pipe in the API 5L series due to its exceptional balance of strength, cost-effectiveness, and versatility. It offers sufficient mechanical properties to handle moderate pressures and harsh environmental conditions, making it suitable for a wide range of applications, including oil and gas transmission, water supply systems, and structural uses. Grade B pipes are also highly weldable and formable, which facilitates easier installation and customization. Additionally, they comply with stringent industry standards, ensuring reliability and safety. Their corrosion resistance further enhances their durability and reduces maintenance costs. Overall, these factors make API 5L Grade B an ideal choice for many pipeline projects, especially where budget constraints and versatility are key considerations.

API5L GR.B PIPE

Subcategory

Keyword

- Details

-

Basic Information

API 5L GR.B is a specification standard for steel pipes used in transmission pipeline systems. These pipes are designed to transport natural gas, petroleum, and other fluids in the oil and gas industry.API5L GR.B PIPE

Grades: GR.A, GR.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Wall Thickness Range: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Manufacture Types: Both seamless and welded (ERW and LSAW).

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Bare, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP,.CWC (Concrete Weight Coated) CRA Clad or Lined.

Chemical Composition● Carbon (C): Maximum 0.28%

● Manganese (Mn): Maximum 1.20%

● Phosphorus (P): Maximum 0.030%

● Sulfur (S): Maximum 0.030%

● Silicon (Si): Maximum 0.40%

Carbon (C): Carbon is a critical element that enhances the strength and hardness of the steel. However, too much carbon can reduce ductility and weldability. The controlled carbon content in Grade B pipes ensures a balance between strength and weldability.

Manganese (Mn): Manganese acts as a deoxidizer, removing dissolved oxygen from the molten steel, which helps prevent inclusions that can weaken the steel. It also increases the yield strength and tensile strength of the pipe.

Phosphorus (P) and Sulfur (S): Phosphorus and sulfur can have detrimental effects on the steel's properties. High levels of phosphorus can lead to brittleness and cracking, while sulfur can cause hot cracking during welding and hydrogen-induced cracking. Strict limits ensure the pipe remains ductile and weldable.

Silicon (Si): Silicon improves deoxidation and desulfurization properties, enhancing weldability and corrosion resistance. It also promotes the formation of a protective oxide layer on the steel's surface.

Mechanical Properties

● Tensile Strength: Minimum 415 MPa

● Yield Strength: Minimum 245 MPa

● Elongation: Typically around 23%, depending on pipe thickness.

This makes them suitable for a wide range of applications, including high-pressure and corrosive environments. The moderate strength ensures that the pipes can withstand the demands of transporting oil, natural gas, and other fluids without being overly expensive or difficult to fabricate .

Applications And AdvantagesApplications

● Transmission Pipelines: Transporting crude oil, natural gas, and other petroleum products from production sources to processing locations.

● Distribution Pipelines: Distributing refined products such as gasoline and diesel to distribution terminals.

● Subsea Pipelines: Used in offshore installations to transfer oil and gas from the seabed to the surface.Advantages

● High Strength: API 5L GR.B pipes have high tensile and yield strengths, making them suitable for high-pressure applications.

● Good Weldability: The controlled carbon content ensures good weldability, which is crucial for pipeline construction.

● Corrosion Resistance: The pipes are designed to withstand corrosive environments, ensuring long service life.

● Reliability: Strict manufacturing processes and quality control ensure high reliability and consistency in performance.

Why Is API 5L Grade B A Relatively Commonly Used Line Pipe In The API 5L Series?

API 5L Grade B is the most commonly used line pipe in the API 5L series due to its exceptional balance of strength, cost-effectiveness, and versatility. It offers sufficient mechanical properties to handle moderate pressures and harsh environmental conditions, making it suitable for a wide range of applications, including oil and gas transmission, water supply systems, and structural uses. Grade B pipes are also highly weldable and formable, which facilitates easier installation and customization. Additionally, they comply with stringent industry standards, ensuring reliability and safety. Their corrosion resistance further enhances their durability and reduces maintenance costs. Overall, these factors make API 5L Grade B an ideal choice for many pipeline projects, especially where budget constraints and versatility are key considerations.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn