- Details

-

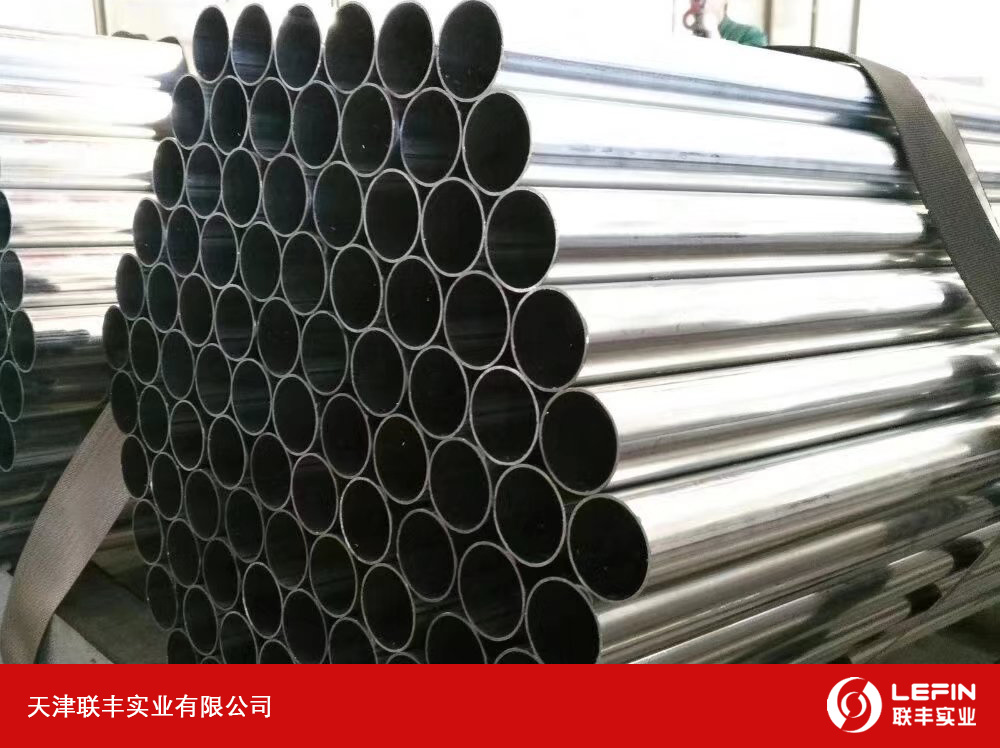

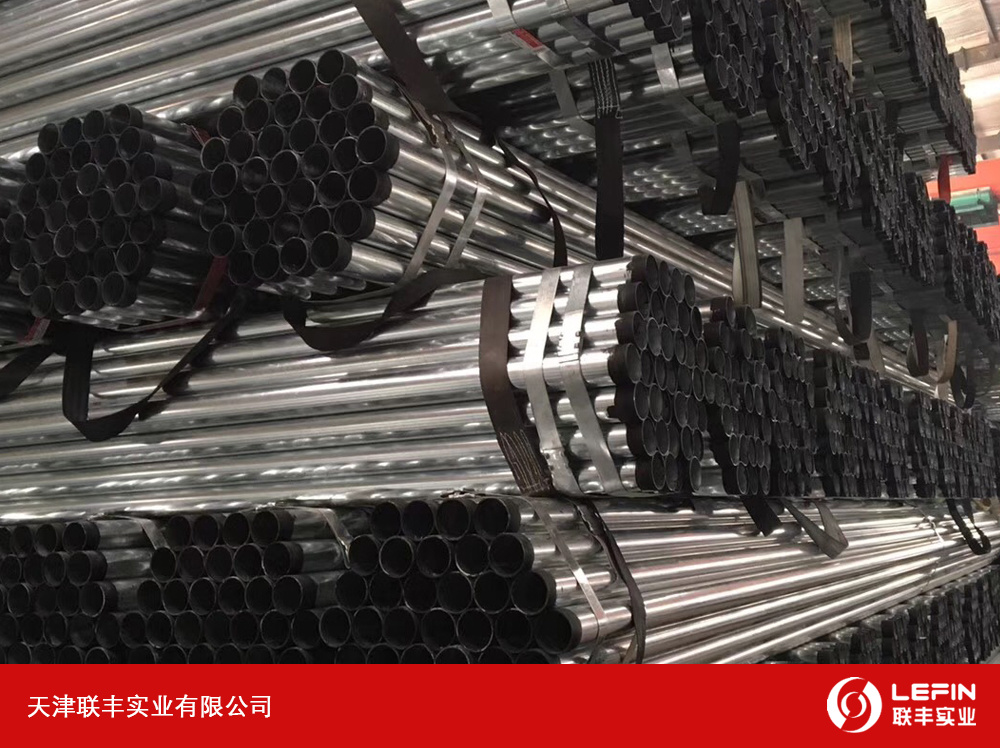

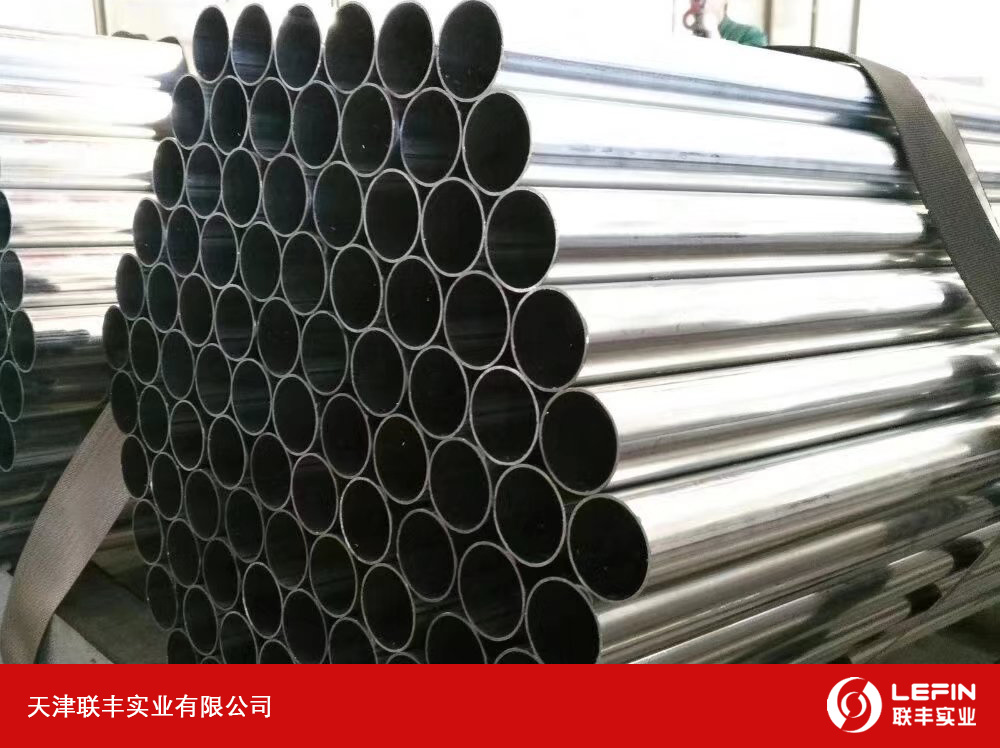

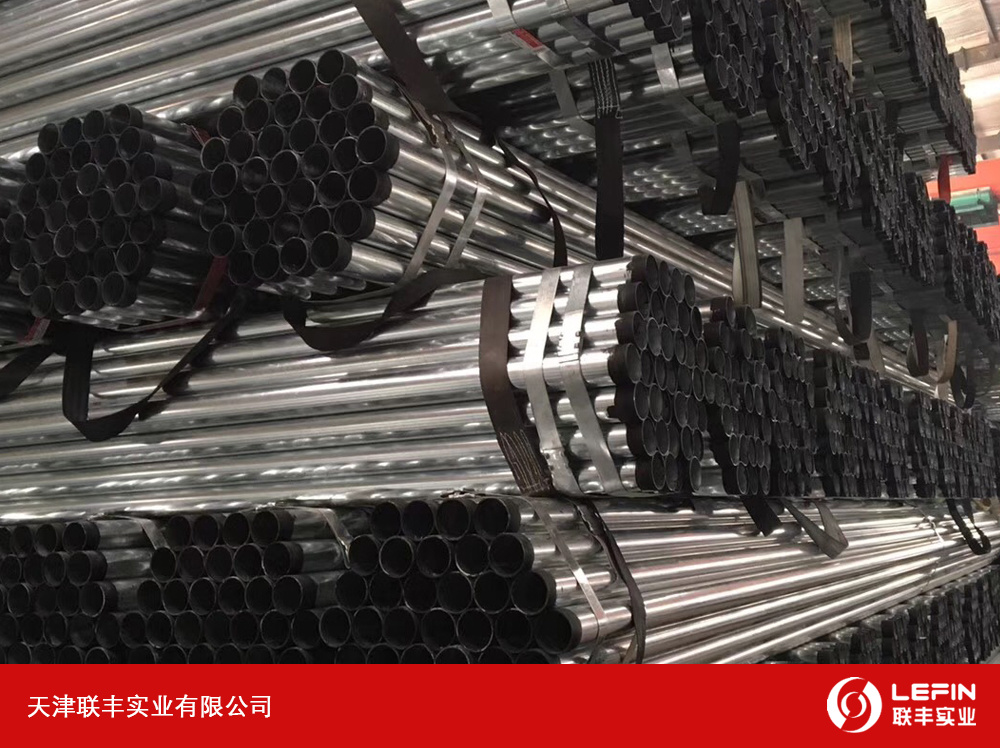

EN 39 SCAFFOLDING PIPE

Description: EN39 scaffolding pipe

Standard: EN39

Grade: S235GT, S355GT

Contact: Nina Wang

Whatsapp: 008618892236531

Email: nina@lefinsteel.com

Specification Scaffolding pipe Outside diameter 48.3(1 1/2 INCH) Wall thickness 3.2MM/4MM Length 1-12M, normally 6M, also depends on the requirements Zinc coating Normally 40 micron(280g/m²), also depends on the requirements Surface treatment Engrave, embossing, cutting Chemical element content S235GT S355GT Carbon (C) Max 0.20% Max 0.22% Manganese (Mn) Max 1.40% Max 1.60% Phosphorus (P) Max 0.040% Max 0.040% Sulfur (S) Max 0.040% Max 0.040% Mechanical properties S235GT S355GT Tensile Strength Minimum of 340 MPa Minimum of 470 MPa Yield Strength Minimum of 235 MPa Minimum of 355 MPa Elongation Minimum of 20% on a gauge length of 5.65 √S₀ (where S₀ is the original cross-sectional area). Minimum of 20% on a gauge length of 5.65 √S₀. Processing process:

Raw Material Preparation (Steel Coil) → Slitting (Cutting to Width) → Forming (Roll Forming) →Welding (ERW or Furnace Welding) →Weld Seam Processing (Normalizing, Grinding) → Sizing and Straightening → Cutting to Length → Surface Treatment (Galvanizing, Coating) → Inspection and Testing → Marking and Packaging

Advantages:

1. High intensity

Load Capacity: EN39 pipe, especially grades such as S235GT and S355GT, have high tensile and yield strengths, allowing them to support heavy loads.

Structural Integrity: These pipes have excellent structural integrity, ensuring the safety and stability of the scaffolding structure.

2. Durability

Long service life: EN39 scaffolding pipes can withstand the harsh conditions of construction sites, including exposure to the elements, ensuring a longer service life.

Galvanized Coating: Typically, EN39 pipes are galvanized to provide enhanced corrosion resistance. This makes them suitable for outdoor use, extending their service life even in corrosive environments.

4. Easy to install

Dimensional Consistency: EN39 pipe has consistent dimensions and tolerances, simplifying on-site assembly and installation.

Good weldability: These pipes are easy to weld, making erecting and dismantling the scaffolding structure simple.

5. Versatility

Multiple Applications: EN39 pipe can be used in a variety of scaffolding configurations and other temporary structures, making it suitable for different types of projects from small construction to large infrastructure projects.

Compatibility: These pipes are compatible with standard scaffolding fittings and fittings, making them easy to integrate into existing scaffolding systems.6. Security

Load Distribution: These pipes are designed to evenly distribute loads, minimizing stress points and ensuring the scaffold remains stable under load.

7. Cost-effectiveness

Reduced Maintenance Costs: The durability and corrosion resistance of EN39 pipe reduces the need for frequent maintenance or replacement, resulting in long-term cost savings.

Reusable: EN39 scaffolding tubes can be used multiple times for different projects.

8. Environmental considerations

Recyclable: EN39 scaffolding tubes are made of steel and are fully recyclable, making them an environmentally friendly choice for construction projects.

Application:

1. Scaffolding Systems

Temporary Work Platforms: EN39 pipes are used to construct scaffolding that provides workers with safe and stable platforms for working at height during construction, maintenance, and repair projects.

Access Scaffolds: These pipes are used to build scaffolds that allow workers to access hard-to-reach areas of a building or structure, such as facades, ceilings, and roofs.

Suspended Scaffolds: EN39 pipes are also employed in suspended scaffolding systems, where the scaffold is hung from the top of a building or structure, providing access to the sides and underside.

2. Shoring Systems

Support for Excavations: EN39 scaffolding pipes are used in shoring systems to provide temporary support to the walls of excavations, preventing collapse and ensuring the safety of workers.

Formwork Support: These pipes are used to create shoring systems that support formwork for concrete structures, ensuring that the forms remain stable during the pouring and curing processes.

3. Temporary Structures

Event Structures: EN39 pipes are often used to build temporary structures for events, such as stages, grandstands, and tents. Their strength and versatility make them suitable for creating stable and reliable frameworks.

Temporary Shelters: In emergency situations, EN39 pipes can be used to construct temporary shelters and housing, providing quick and reliable solutions in disaster-affected areas.

4.Demolition work

Demolition Support: EN39 Scaffolding Tubes are used to create temporary structures to support a building or part of a building during demolition, ensuring that the demolition process is carried out safely and efficiently.

5. Transportation and Logistics

Loading and unloading platforms: EN39 scaffolding pipes are used to build temporary loading and unloading platforms and ramps in transportation and logistics operations to provide channels for loading and unloading materials.

Temporary Storage Structures: These pipes can be used to build temporary storage facilities and structures such as storage racks or shelters.

6. Marine and offshore applications

Shipbuilding and Repair: EN39 ducting is used in scaffolding systems for shipbuilding, repair and maintenance to provide access to different parts of the ship.

Offshore Platforms: These pipes are also used in scaffolding systems on offshore oil rigs and platforms where safe access to elevated areas is required.

EN 39 SCAFFOLDING PIPE

Standard: EN39

Grade: S235GT, S355GT

Subcategory

Keyword

- Details

-

EN 39 SCAFFOLDING PIPE

Description: EN39 scaffolding pipe

Standard: EN39

Grade: S235GT, S355GT

Contact: Nina Wang

Whatsapp: 008618892236531

Email: nina@lefinsteel.com

Specification Scaffolding pipe Outside diameter 48.3(1 1/2 INCH) Wall thickness 3.2MM/4MM Length 1-12M, normally 6M, also depends on the requirements Zinc coating Normally 40 micron(280g/m²), also depends on the requirements Surface treatment Engrave, embossing, cutting Chemical element content S235GT S355GT Carbon (C) Max 0.20% Max 0.22% Manganese (Mn) Max 1.40% Max 1.60% Phosphorus (P) Max 0.040% Max 0.040% Sulfur (S) Max 0.040% Max 0.040% Mechanical properties S235GT S355GT Tensile Strength Minimum of 340 MPa Minimum of 470 MPa Yield Strength Minimum of 235 MPa Minimum of 355 MPa Elongation Minimum of 20% on a gauge length of 5.65 √S₀ (where S₀ is the original cross-sectional area). Minimum of 20% on a gauge length of 5.65 √S₀. Processing process:

Raw Material Preparation (Steel Coil) → Slitting (Cutting to Width) → Forming (Roll Forming) →Welding (ERW or Furnace Welding) →Weld Seam Processing (Normalizing, Grinding) → Sizing and Straightening → Cutting to Length → Surface Treatment (Galvanizing, Coating) → Inspection and Testing → Marking and Packaging

Advantages:

1. High intensity

Load Capacity: EN39 pipe, especially grades such as S235GT and S355GT, have high tensile and yield strengths, allowing them to support heavy loads.

Structural Integrity: These pipes have excellent structural integrity, ensuring the safety and stability of the scaffolding structure.

2. Durability

Long service life: EN39 scaffolding pipes can withstand the harsh conditions of construction sites, including exposure to the elements, ensuring a longer service life.

Galvanized Coating: Typically, EN39 pipes are galvanized to provide enhanced corrosion resistance. This makes them suitable for outdoor use, extending their service life even in corrosive environments.

4. Easy to install

Dimensional Consistency: EN39 pipe has consistent dimensions and tolerances, simplifying on-site assembly and installation.

Good weldability: These pipes are easy to weld, making erecting and dismantling the scaffolding structure simple.

5. Versatility

Multiple Applications: EN39 pipe can be used in a variety of scaffolding configurations and other temporary structures, making it suitable for different types of projects from small construction to large infrastructure projects.

Compatibility: These pipes are compatible with standard scaffolding fittings and fittings, making them easy to integrate into existing scaffolding systems.6. Security

Load Distribution: These pipes are designed to evenly distribute loads, minimizing stress points and ensuring the scaffold remains stable under load.

7. Cost-effectiveness

Reduced Maintenance Costs: The durability and corrosion resistance of EN39 pipe reduces the need for frequent maintenance or replacement, resulting in long-term cost savings.

Reusable: EN39 scaffolding tubes can be used multiple times for different projects.

8. Environmental considerations

Recyclable: EN39 scaffolding tubes are made of steel and are fully recyclable, making them an environmentally friendly choice for construction projects.

Application:

1. Scaffolding Systems

Temporary Work Platforms: EN39 pipes are used to construct scaffolding that provides workers with safe and stable platforms for working at height during construction, maintenance, and repair projects.

Access Scaffolds: These pipes are used to build scaffolds that allow workers to access hard-to-reach areas of a building or structure, such as facades, ceilings, and roofs.

Suspended Scaffolds: EN39 pipes are also employed in suspended scaffolding systems, where the scaffold is hung from the top of a building or structure, providing access to the sides and underside.

2. Shoring Systems

Support for Excavations: EN39 scaffolding pipes are used in shoring systems to provide temporary support to the walls of excavations, preventing collapse and ensuring the safety of workers.

Formwork Support: These pipes are used to create shoring systems that support formwork for concrete structures, ensuring that the forms remain stable during the pouring and curing processes.

3. Temporary Structures

Event Structures: EN39 pipes are often used to build temporary structures for events, such as stages, grandstands, and tents. Their strength and versatility make them suitable for creating stable and reliable frameworks.

Temporary Shelters: In emergency situations, EN39 pipes can be used to construct temporary shelters and housing, providing quick and reliable solutions in disaster-affected areas.

4.Demolition work

Demolition Support: EN39 Scaffolding Tubes are used to create temporary structures to support a building or part of a building during demolition, ensuring that the demolition process is carried out safely and efficiently.

5. Transportation and Logistics

Loading and unloading platforms: EN39 scaffolding pipes are used to build temporary loading and unloading platforms and ramps in transportation and logistics operations to provide channels for loading and unloading materials.

Temporary Storage Structures: These pipes can be used to build temporary storage facilities and structures such as storage racks or shelters.

6. Marine and offshore applications

Shipbuilding and Repair: EN39 ducting is used in scaffolding systems for shipbuilding, repair and maintenance to provide access to different parts of the ship.

Offshore Platforms: These pipes are also used in scaffolding systems on offshore oil rigs and platforms where safe access to elevated areas is required.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn