- Details

-

Basic Information

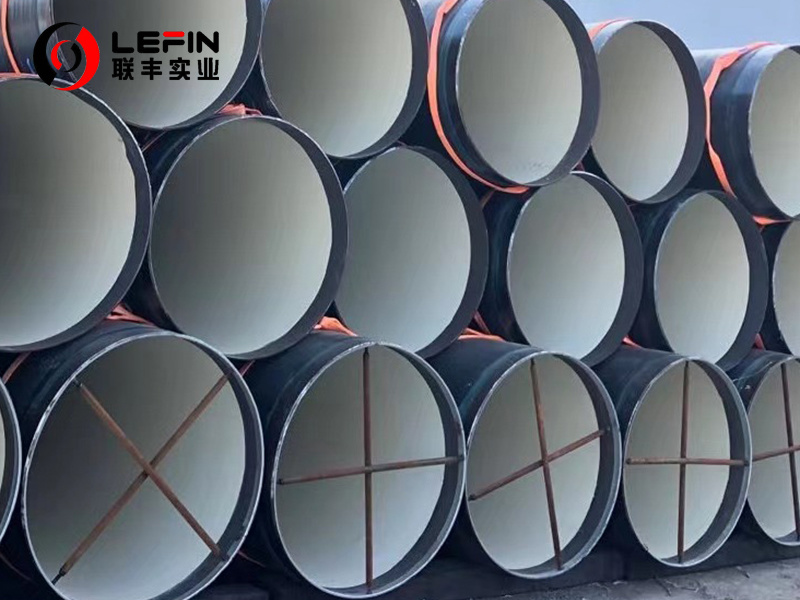

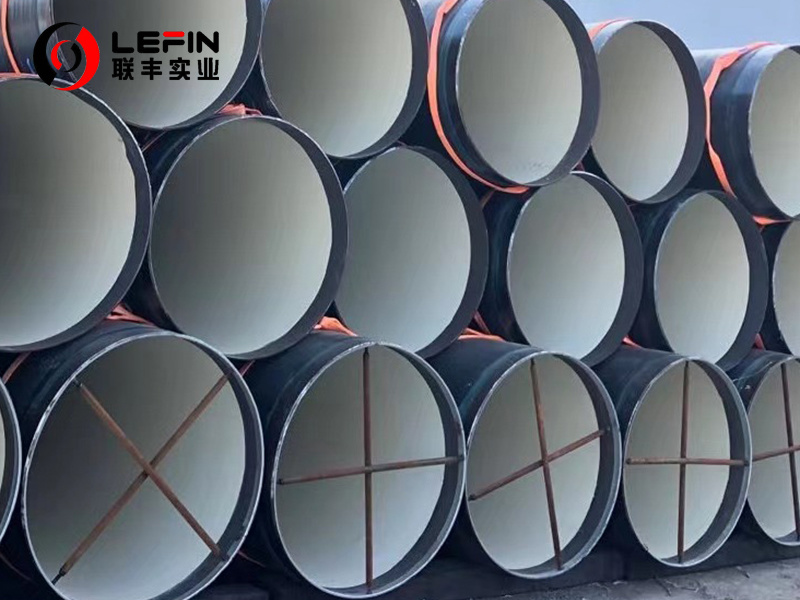

API5L PSL2 LSAW PIPE

Grades: Grade A, Grade B, A25, X42, X46, X52, X56, X60, X65, X70,X80M,X90M,X100M,X120M

Product Specification Level: PSL1, PSL2

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: LSAW

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Bare, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Chemical Composition

Grade Chemical composition analysis of psl2 steel pipe t≤25mm Cb Si Mn P S Seamless pipe and welded pipe L245R/BR 0.24 0.40 1.20 0.025 0.015 L290R/X42R 0.24 0.40 1.20 0.025 0.015 L245N/BN 0.24 0.40 1.20 0.025 0.015 L290N/X42N 0.24 0.40 1.20 0.025 0.015 L320N/X46N 0.24 0.40 1.40 0.025 0.015 L360N/X52N 0.24 0.45 1.40 0.025 0.015 L390N/X56N 0.24 0.45 1.40 0.025 0.015 L415N/X60N 0.24f 0.45 1.40f 0.025 0.015 L245Q/BQ 0.18 0.45f 1.40 0.025 0.015 L290Q/X42Q 0.18 0.45 1.40 0.025 0.015 L320Q/X46Q 0.18 0.45 1.40 0.025 0.015 L360Q/X52Q 0.18 0.45 1.50 0.025 0.015 L390Q/X56Q 0.18 0.45 1.50 0.025 0.015 L415Q/X60Q 0.18f 0.45f 1.70f 0.025 0.015 L450Q/X65Q 0.18f 0.45f 1.70f 0.025 0.015 L485Q/X70Q 0.18f 0.45f 1.80f 0.025 0.015 L555Q/X80Q 0.18f 0.45f 1.90f 0.025 0.015 L625Q/X90Q 0.16f 0.45f 1.90 0.020 0.010 L690Q/X100Q 0.16f 0.45f 1.90 0.020 0.010 welded pipe L245M/BM 0.22 0.45 1.20 0.025 0.015 L290M/X42M 0.22 0.45 1.30 0.025 0.015 L320M/X46M 0.22 0.45 1.30 0.025 0.015 L360M/X52M 0.22 0.45 1.40 0.025 0.015 L390M/X56M 0.22 0.45 1.40 0.025 0.015 L415M/X60M 0.12f 0.45f 1.60f 0.025 0.015 L450M/X65M 0.12f 0.45f 1.60f 0.025 0.015 L485M/X70M 0.12f 0.45f 1.70f 0.025 0.015 L555M/X80M 0.12f 0.45f 1.85f 0.025 0.015 L625M/X90M 0.10 0.55f 2.10f 0.020 0.010 L690M/X100M 0.10 0.55f 2.10f 0.020 0.010 L830M/X120M 0.10 0.55f 2.10f 0.020 0.010 f.Unless otherwise agreed. Physical Requirements

Grade Seamless pipe and welded pipe Yield strength

Rt0,5

MPa(psi)Tensile strength

Rm

Mpa(psi)Yield ratio

Rt0,5/RmMIN MAX MIN MAX MAX L245R/BR

L245N/BN

L245Q/BQ

L245M/BM245

(35,500)450

(65,300)415

(60,200)655

(95,000)0.93 L290R/X42R

L290N/X42N

L290Q/X42Q

L290M/X42M290

(42,100)495

(71,800)415

(60,200)0.93 L320N/X46N

L320Q/X46Q

L320M/X46M320

(46,400)525

(76,100)435

(63,100)655

(95,000)0.93 L360N/X52N

L360Q/X52Q

L360M/X52M360

(52,200)530

(76,900)460

(66,700)760

(110,200)0.93 L390N/X56N

L390Q/X56Q

L390M/X56M390

(56,600)545

(79,000)490

(71,100)760

(110,200)0.93 L415N/X60N

L415Q/X60Q

L415M/X60M415

(60,200)565

(81,900)520

(75,400)760

(110,200)0.93 L450Q/X65Q

L450M/X65M450

(65,300)600

(87,000)535

(77,600)760

(110,200)0.93 L485Q/X70Q

L485M/X70M485

(70,300)635

(92,100)570

(82,700)760

(110,200)0.93 L555Q/X80Q

L555M/X80M555

(80,500)705

(102,300)625

(90,600)825

(119,700)0.93 L625M/X90M 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.95 L625Q/X90Q 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.97g L690M/X100M 690b(100,100)b 840b(121,800)b 760

(110,200)990

(143,600)0.97h L690Q/X100Q 690b(100,100)b 840b(121,800)b 760

(110,200)990

(143,600)0.97h L830M/X120M 830b(120,400)b 1050b(152,300)b 915

(132,700)1145

(166,100)0.99h b. For grades > L625 or X90, Rp0.2 applies. g. Lower values of Rt0.5/Rm may be specified by agreement. h. For grades > L625 or X90, Rp0.2 /Rm applies. Lower values of Rp0.2 /Rm may be specified by agreement. Applications

API 5L PSL2 LSAW PIPE is a high performance pipeline pipe with high strength, high toughness and good corrosion resistance, which is widely used in many fields:

The oil and gas industry

1.Long Distance pipelinesAPI 5L PSL2 LSAW PIPE can be used to build long distance oil and gas pipelines both onshore and offshore. Its high strength-to-weight ratio enables it to withstand high internal pressures while maintaining a relatively lightweight construction that is easy to transport and install, and cost effective. For example, the X60Q-class tube is suitable for traversing a variety of terrain, including challenging environments such as frozen soils or earthquake-prone areas, and can efficiently transport large quantities of oil or gas over long distances.

2.Offshore platform riser system

In offshore oil and gas production, the line pipe can be used to connect subsea oil and gas Wells to offshore platform riser system. It not only needs to withstand the pressure of internal oil and gas, but also to withstand the static pressure of external sea water and the dynamic load caused by ocean currents and waves, its corrosion resistance is particularly important in the Marine environment, and can effectively resist the corrosion of sea water.

3.High pressure delivery systems for the petrochemical industryIn refineries and chemical plants, API 5L PSL2 LSAW pipes can be used to transport a wide range of hydrocarbon products and process fluids under high pressure and temperature conditions. The pipeline is resistant to hydrogen induced cracking (HIC) and stress corrosion cracking (SCC), making it suitable for acidic service applications dealing with the presence of hydrogen sulfide.

Energy field

1.Hydrogen transport infrastructureAs the world transitions to clean energy, hydrogen transport infrastructure is becoming increasingly important. The high strength and toughness of API 5L PSL2 LSAW PIPE make it a potential candidate for addressing unique challenges associated with hydrogen transport, such as hydrogen embrittleness.

2.High-pressure power plant boiler pipeIt can be used for high-pressure power plant boiler pipe system, its excellent mechanical properties and corrosion resistance can meet the high pressure, high temperature working environment requirements, to ensure the stable operation of power generation equipment.

Urban infrastructure

1.Urban gas transmission network

It can be used for urban gas transmission to provide stable gas supply for urban residents and industrial users. Its good sealing and corrosion resistance ensure the safety and reliability of gas during transportation.

2.Water piping

The API 5L PSL2 LSAW PIPE is also an ideal choice for large water projects that require high pressure piping. Its durability and corrosion resistance make it suitable for long-term use in water supply systems, ensuring a reliable water supply to urban areas and industrial facilities.

API5L PSL2 LSAW PIPE

Subcategory

Keyword

- Details

-

Basic Information

API5L PSL2 LSAW PIPE

Grades: Grade A, Grade B, A25, X42, X46, X52, X56, X60, X65, X70,X80M,X90M,X100M,X120M

Product Specification Level: PSL1, PSL2

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: LSAW

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Bare, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Chemical Composition

Grade Chemical composition analysis of psl2 steel pipe t≤25mm Cb Si Mn P S Seamless pipe and welded pipe L245R/BR 0.24 0.40 1.20 0.025 0.015 L290R/X42R 0.24 0.40 1.20 0.025 0.015 L245N/BN 0.24 0.40 1.20 0.025 0.015 L290N/X42N 0.24 0.40 1.20 0.025 0.015 L320N/X46N 0.24 0.40 1.40 0.025 0.015 L360N/X52N 0.24 0.45 1.40 0.025 0.015 L390N/X56N 0.24 0.45 1.40 0.025 0.015 L415N/X60N 0.24f 0.45 1.40f 0.025 0.015 L245Q/BQ 0.18 0.45f 1.40 0.025 0.015 L290Q/X42Q 0.18 0.45 1.40 0.025 0.015 L320Q/X46Q 0.18 0.45 1.40 0.025 0.015 L360Q/X52Q 0.18 0.45 1.50 0.025 0.015 L390Q/X56Q 0.18 0.45 1.50 0.025 0.015 L415Q/X60Q 0.18f 0.45f 1.70f 0.025 0.015 L450Q/X65Q 0.18f 0.45f 1.70f 0.025 0.015 L485Q/X70Q 0.18f 0.45f 1.80f 0.025 0.015 L555Q/X80Q 0.18f 0.45f 1.90f 0.025 0.015 L625Q/X90Q 0.16f 0.45f 1.90 0.020 0.010 L690Q/X100Q 0.16f 0.45f 1.90 0.020 0.010 welded pipe L245M/BM 0.22 0.45 1.20 0.025 0.015 L290M/X42M 0.22 0.45 1.30 0.025 0.015 L320M/X46M 0.22 0.45 1.30 0.025 0.015 L360M/X52M 0.22 0.45 1.40 0.025 0.015 L390M/X56M 0.22 0.45 1.40 0.025 0.015 L415M/X60M 0.12f 0.45f 1.60f 0.025 0.015 L450M/X65M 0.12f 0.45f 1.60f 0.025 0.015 L485M/X70M 0.12f 0.45f 1.70f 0.025 0.015 L555M/X80M 0.12f 0.45f 1.85f 0.025 0.015 L625M/X90M 0.10 0.55f 2.10f 0.020 0.010 L690M/X100M 0.10 0.55f 2.10f 0.020 0.010 L830M/X120M 0.10 0.55f 2.10f 0.020 0.010 f.Unless otherwise agreed. Physical Requirements

Grade Seamless pipe and welded pipe Yield strength

Rt0,5

MPa(psi)Tensile strength

Rm

Mpa(psi)Yield ratio

Rt0,5/RmMIN MAX MIN MAX MAX L245R/BR

L245N/BN

L245Q/BQ

L245M/BM245

(35,500)450

(65,300)415

(60,200)655

(95,000)0.93 L290R/X42R

L290N/X42N

L290Q/X42Q

L290M/X42M290

(42,100)495

(71,800)415

(60,200)0.93 L320N/X46N

L320Q/X46Q

L320M/X46M320

(46,400)525

(76,100)435

(63,100)655

(95,000)0.93 L360N/X52N

L360Q/X52Q

L360M/X52M360

(52,200)530

(76,900)460

(66,700)760

(110,200)0.93 L390N/X56N

L390Q/X56Q

L390M/X56M390

(56,600)545

(79,000)490

(71,100)760

(110,200)0.93 L415N/X60N

L415Q/X60Q

L415M/X60M415

(60,200)565

(81,900)520

(75,400)760

(110,200)0.93 L450Q/X65Q

L450M/X65M450

(65,300)600

(87,000)535

(77,600)760

(110,200)0.93 L485Q/X70Q

L485M/X70M485

(70,300)635

(92,100)570

(82,700)760

(110,200)0.93 L555Q/X80Q

L555M/X80M555

(80,500)705

(102,300)625

(90,600)825

(119,700)0.93 L625M/X90M 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.95 L625Q/X90Q 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.97g L690M/X100M 690b(100,100)b 840b(121,800)b 760

(110,200)990

(143,600)0.97h L690Q/X100Q 690b(100,100)b 840b(121,800)b 760

(110,200)990

(143,600)0.97h L830M/X120M 830b(120,400)b 1050b(152,300)b 915

(132,700)1145

(166,100)0.99h b. For grades > L625 or X90, Rp0.2 applies. g. Lower values of Rt0.5/Rm may be specified by agreement. h. For grades > L625 or X90, Rp0.2 /Rm applies. Lower values of Rp0.2 /Rm may be specified by agreement. Applications

API 5L PSL2 LSAW PIPE is a high performance pipeline pipe with high strength, high toughness and good corrosion resistance, which is widely used in many fields:

The oil and gas industry

1.Long Distance pipelinesAPI 5L PSL2 LSAW PIPE can be used to build long distance oil and gas pipelines both onshore and offshore. Its high strength-to-weight ratio enables it to withstand high internal pressures while maintaining a relatively lightweight construction that is easy to transport and install, and cost effective. For example, the X60Q-class tube is suitable for traversing a variety of terrain, including challenging environments such as frozen soils or earthquake-prone areas, and can efficiently transport large quantities of oil or gas over long distances.

2.Offshore platform riser system

In offshore oil and gas production, the line pipe can be used to connect subsea oil and gas Wells to offshore platform riser system. It not only needs to withstand the pressure of internal oil and gas, but also to withstand the static pressure of external sea water and the dynamic load caused by ocean currents and waves, its corrosion resistance is particularly important in the Marine environment, and can effectively resist the corrosion of sea water.

3.High pressure delivery systems for the petrochemical industryIn refineries and chemical plants, API 5L PSL2 LSAW pipes can be used to transport a wide range of hydrocarbon products and process fluids under high pressure and temperature conditions. The pipeline is resistant to hydrogen induced cracking (HIC) and stress corrosion cracking (SCC), making it suitable for acidic service applications dealing with the presence of hydrogen sulfide.

Energy field

1.Hydrogen transport infrastructureAs the world transitions to clean energy, hydrogen transport infrastructure is becoming increasingly important. The high strength and toughness of API 5L PSL2 LSAW PIPE make it a potential candidate for addressing unique challenges associated with hydrogen transport, such as hydrogen embrittleness.

2.High-pressure power plant boiler pipeIt can be used for high-pressure power plant boiler pipe system, its excellent mechanical properties and corrosion resistance can meet the high pressure, high temperature working environment requirements, to ensure the stable operation of power generation equipment.

Urban infrastructure

1.Urban gas transmission network

It can be used for urban gas transmission to provide stable gas supply for urban residents and industrial users. Its good sealing and corrosion resistance ensure the safety and reliability of gas during transportation.

2.Water piping

The API 5L PSL2 LSAW PIPE is also an ideal choice for large water projects that require high pressure piping. Its durability and corrosion resistance make it suitable for long-term use in water supply systems, ensuring a reliable water supply to urban areas and industrial facilities.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn