- Details

-

Basic Information

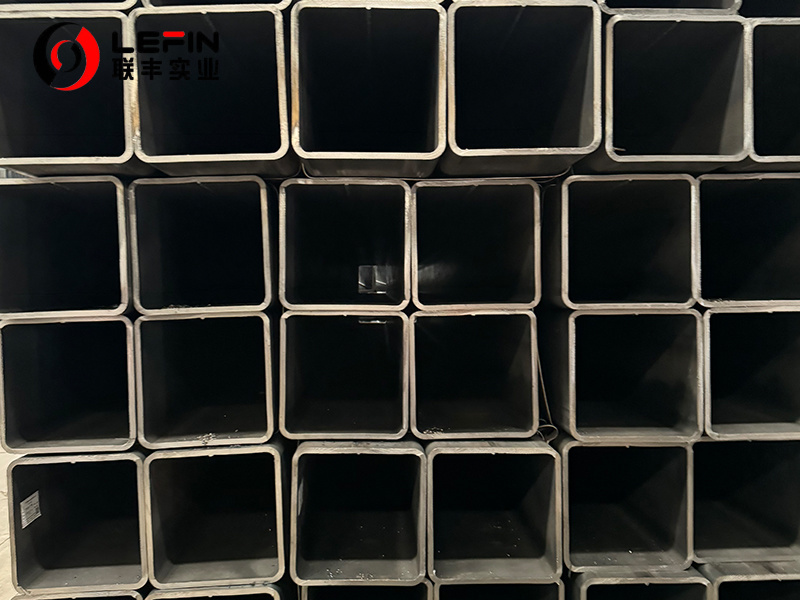

JIS G3444 STKR500 SCAFFOLDING PIPE

Standard: JIS G3444

Grade: STKR400 STKR500

Outside diameter: 20*20 - 1200*1200 Wall Thickness: 1.3 - 16mm

Outside diameter: 20*20 - 1200*1500 Wall Thickness: 1.2 - 16mm

The Wall Thickness Tolerance: ±5%

Length: normally 5.8m, 6m, 12m or as your required

Surface Treatment: Bare Finish, Painting, Oiling, Galvanzation, 3PE, FBE coated......

Chemical Composition

CHEMICAL COMPOSITION OF JIS G3444,%MAX

GRADE

C

Si

Mn

P

S

STK 400

0.25%MAX

-

-

0.04%MAX

0.04%MAX

STK 500

0.24%MAX

0.35%MAX

0.3-1.3

0.04%MAX

0.04%MAX

Physical Requirement

MECHANICAL PROPERTIES OF JIS G3444

GRADE

Tensile Strength N/mm2

Yield Point or Proof Stress N/mm2

Weld Tensile N/mm2

Flattening Resistance Strength

Bendability

Distance between Flat Plates (H)

Bending Angle, a)

Inside Radius

Applicable Outside Diameter

All Outside Diameters

All Outside Diameters

All Outside Diameters

All Outside Diameters

50 mm or under

STK 400

400min

235min

400min

2/3D

90°

6D

STK 500

500min

355min

500min

7/8D

90°

6D

Features

01.Mechanical property

- High tensile strength: the tensile strength of STK500 is ≥500N/mm², which can withstand large tensile forces, and is suitable for scaffolding systems that bear heavy loads, ensuring the stability and safety of scaffolding during construction.- Large yield strength: its yield strength is ≥355N/mm², when subjected to external force, it can withstand large deformation without damage, to ensure the reliability of the scaffold during use.02.Chemical composition

- Low carbon content: carbon content ≤0.24%, the lower carbon content helps to improve the welding performance and toughness of the steel pipe, reduce the crack generation in the welding process, but also helps to improve the corrosion resistance of the steel pipe.- Moderate silicon content: silicon content ≤0.35%, silicon can play a certain deoxidation role in steel, while improving the strength and hardness of steel to a certain extent, but too high silicon content will affect the toughness of steel, STK500 silicon content is controlled within a reasonable range.- Wide range of manganese content: manganese content is 0.3% ~ 1.3%, manganese is a good alloying element, can improve the strength and hardness of steel, but also improve the hardenability of steel, so that the steel pipe in the heat treatment process easier to obtain uniform organization and performance.- Low phosphorus and sulfur content: phosphorus content ≤0.04%, sulfur content ≤0.04%, phosphorus and sulfur are harmful elements in steel, they will reduce the plasticity and toughness of steel, increase the brittleness of steel, STK500 strictly control the phosphorus and sulfur content, to ensure the excellent performance of the steel pipe.03.Surface treatment

- Galvanized anticorrosion: usually using hot dip galvanized method for surface treatment, galvanized layer thickness is generally 40 microns (280g/m²), galvanized layer can effectively isolate the steel pipe and air, water and other corrosive media contact, greatly improve the corrosion resistance of the steel pipe, make it more suitable for use in outdoor harsh environment, extend the service life of the scaffold.- Other surface treatment: It can also be marked, embossed, cut and other surface treatment as required to meet different construction marking and processing requirements.04.Processing technology

- Mature manufacturing process: The use of high-quality steel strip as raw materials, through cutting, forming, welding (such as ERW or furnace welding), weld treatment (such as normalizing, grinding), sizing straightening, cutting, surface treatment and a series of advanced processing technology manufacturing, to ensure the quality and performance of the steel pipe stability.- JIS G3444 STK500 SCAFFOLDING PIPE is easy to cut, weld and assemble, which makes the scaffolding erection and removal more convenient, can effectively shorten the construction period, improve the construction efficiency.05.Applicability

- Wide range of applications: not only applicable to the scaffolding system in construction, but also for the structural framework of housing construction projects, infrastructure and civil engineering in bridge and road construction scaffolding, shipbuilding and offshore platform scaffolding, industrial facilities maintenance and overhaul scaffolding and various activities and temporary structure construction, has a strong versatility and applicability.- Cost-effective: While ensuring good quality, the price is more reasonable, providing an affordable temporary support system choice for construction projects, helping to reduce construction costs.

JIS G3444 STKR500 SCAFFOLDING PIPE

Subcategory

Keyword

- Details

-

Basic Information

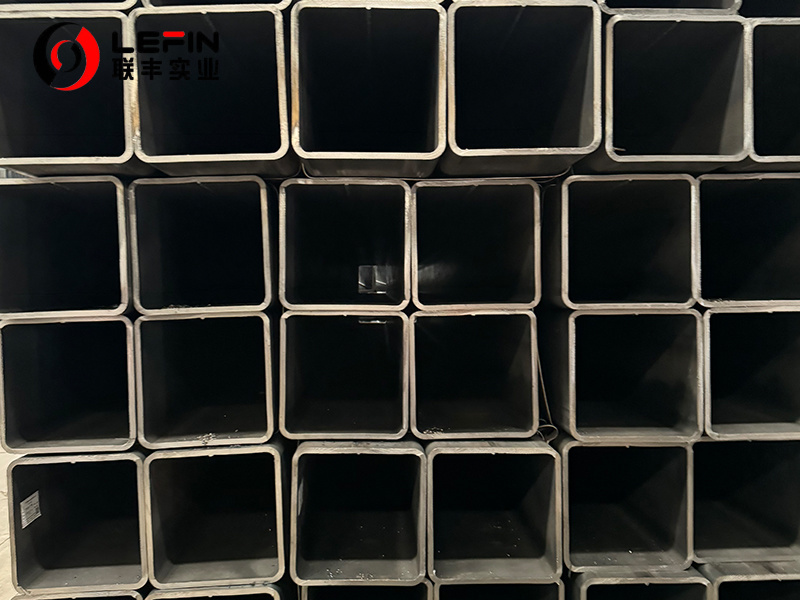

JIS G3444 STKR500 SCAFFOLDING PIPE

Standard: JIS G3444

Grade: STKR400 STKR500

Outside diameter: 20*20 - 1200*1200 Wall Thickness: 1.3 - 16mm

Outside diameter: 20*20 - 1200*1500 Wall Thickness: 1.2 - 16mm

The Wall Thickness Tolerance: ±5%

Length: normally 5.8m, 6m, 12m or as your required

Surface Treatment: Bare Finish, Painting, Oiling, Galvanzation, 3PE, FBE coated......

Chemical Composition

CHEMICAL COMPOSITION OF JIS G3444,%MAX

GRADE

C

Si

Mn

P

S

STK 400

0.25%MAX

-

-

0.04%MAX

0.04%MAX

STK 500

0.24%MAX

0.35%MAX

0.3-1.3

0.04%MAX

0.04%MAX

Physical Requirement

MECHANICAL PROPERTIES OF JIS G3444

GRADE

Tensile Strength N/mm2

Yield Point or Proof Stress N/mm2

Weld Tensile N/mm2

Flattening Resistance Strength

Bendability

Distance between Flat Plates (H)

Bending Angle, a)

Inside Radius

Applicable Outside Diameter

All Outside Diameters

All Outside Diameters

All Outside Diameters

All Outside Diameters

50 mm or under

STK 400

400min

235min

400min

2/3D

90°

6D

STK 500

500min

355min

500min

7/8D

90°

6D

Features

01.Mechanical property

- High tensile strength: the tensile strength of STK500 is ≥500N/mm², which can withstand large tensile forces, and is suitable for scaffolding systems that bear heavy loads, ensuring the stability and safety of scaffolding during construction.- Large yield strength: its yield strength is ≥355N/mm², when subjected to external force, it can withstand large deformation without damage, to ensure the reliability of the scaffold during use.02.Chemical composition

- Low carbon content: carbon content ≤0.24%, the lower carbon content helps to improve the welding performance and toughness of the steel pipe, reduce the crack generation in the welding process, but also helps to improve the corrosion resistance of the steel pipe.- Moderate silicon content: silicon content ≤0.35%, silicon can play a certain deoxidation role in steel, while improving the strength and hardness of steel to a certain extent, but too high silicon content will affect the toughness of steel, STK500 silicon content is controlled within a reasonable range.- Wide range of manganese content: manganese content is 0.3% ~ 1.3%, manganese is a good alloying element, can improve the strength and hardness of steel, but also improve the hardenability of steel, so that the steel pipe in the heat treatment process easier to obtain uniform organization and performance.- Low phosphorus and sulfur content: phosphorus content ≤0.04%, sulfur content ≤0.04%, phosphorus and sulfur are harmful elements in steel, they will reduce the plasticity and toughness of steel, increase the brittleness of steel, STK500 strictly control the phosphorus and sulfur content, to ensure the excellent performance of the steel pipe.03.Surface treatment

- Galvanized anticorrosion: usually using hot dip galvanized method for surface treatment, galvanized layer thickness is generally 40 microns (280g/m²), galvanized layer can effectively isolate the steel pipe and air, water and other corrosive media contact, greatly improve the corrosion resistance of the steel pipe, make it more suitable for use in outdoor harsh environment, extend the service life of the scaffold.- Other surface treatment: It can also be marked, embossed, cut and other surface treatment as required to meet different construction marking and processing requirements.04.Processing technology

- Mature manufacturing process: The use of high-quality steel strip as raw materials, through cutting, forming, welding (such as ERW or furnace welding), weld treatment (such as normalizing, grinding), sizing straightening, cutting, surface treatment and a series of advanced processing technology manufacturing, to ensure the quality and performance of the steel pipe stability.- JIS G3444 STK500 SCAFFOLDING PIPE is easy to cut, weld and assemble, which makes the scaffolding erection and removal more convenient, can effectively shorten the construction period, improve the construction efficiency.05.Applicability

- Wide range of applications: not only applicable to the scaffolding system in construction, but also for the structural framework of housing construction projects, infrastructure and civil engineering in bridge and road construction scaffolding, shipbuilding and offshore platform scaffolding, industrial facilities maintenance and overhaul scaffolding and various activities and temporary structure construction, has a strong versatility and applicability.- Cost-effective: While ensuring good quality, the price is more reasonable, providing an affordable temporary support system choice for construction projects, helping to reduce construction costs.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn