- Details

-

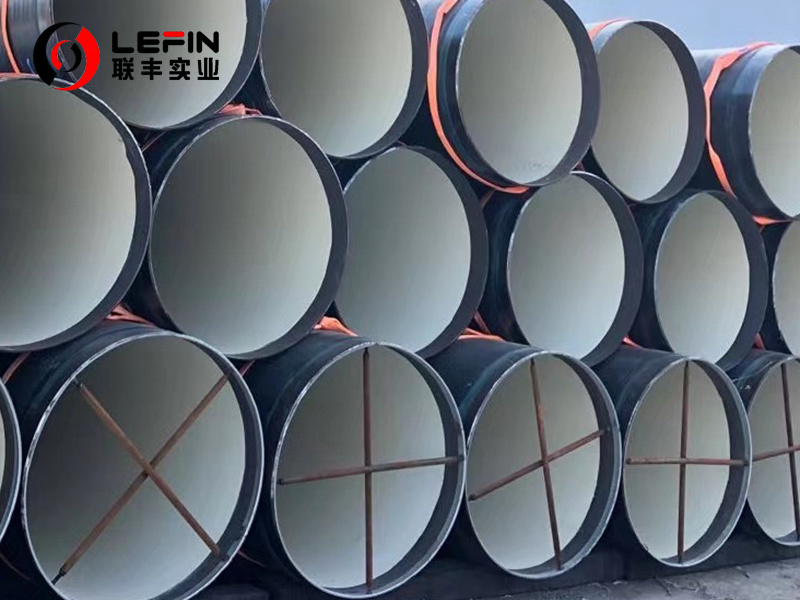

API 5L PSL2

Grades: Grade B, X42, X52, X56, X60, X65, X70, X80

Product Specification Level: PSL1, PSL2, onshore and offshore sour services

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded),

in LSAW, DSAW, SSAW, HSAW

Ends Type: Beveled ends, Plain ends.

Length Range: SRL (Single Random Length), DRL (Double Random Length) , 20 FT (6 meters), 40FT (12 meters) or, customized.

Protection Caps in plastic or iron.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Chemical Composition

Chemical Composition for API 5L PSL2 Pipe with t≤25.0 mm(0.984 in)

Steel Grade

(Steel Name)Mass fraction,based upon heat and product analyses

Carbon

equivalent%,maximum

%,maximum

C b Si

Mn b

P

S

V

Nb

Ti

Other

CEIIw

CEPcm

Seamless and welded pipes

L245R or BR 0.24 0.40 1.20 0.025 0.015 c c 0.04 e,l 0.43 0.25 L290R or X42R 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,I 0.43 0.25 L245N or BN 0.24 0.40 1.20 0.025 0.015 c c 0.04 e,l 0.43 0.25 L290N or X42N 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,l 0.43 0.25 L320N or X46N 0.24 0.40 1.40 0.025 0.015 0.07 0.05 0.04 d,e,I 0.43 0.25 L360N or X52N 0.24 0.45 1.40 0.025 0.015 0.10 0.05 0.04 d,e,I 0.43 0.25 L390N or X56N 0.24 0.45 1.40 0.025 0.015 0.10 0.05 0.04 d,e,I 0.43 0.25 L415N or X60N 0.24 f 0.45 f 1.40 f 0.025 0.015 0.10 0.05 0.04 g,h,l as agreed L245Qor BQ 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L290Q or X42Q 0.18 0.45 1.40 f 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L320Q or X46Q 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360Q or X52Q 0.18 0.45 1.50 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L390Q or X56Q 0.18 0.45 1.50 0.025 0.015 0.07 0.05 0.04 d,e,I 0.43 0.25 L415Q or X60Q 0.18 f 0.45 f 1.70 f 0.025 0.015 g g g h,l 0.43 0.25 L450Q or X65Q 0.18 f 0.45 f 1.70 f 0.025 0.015 g g g h,I 0.43 0.25 L485Q or X70Q 0.18 f 0.45 f 1.80 f 0.025 0.015 g g g h,l 0.43 0.25 L555Q or X80Q 0.18 f 0.45 f 1.90 f 0.025 0.015 g g g i,j as agreed L625Q or X90Q 0.16 0.45 1.90 0.020 0.010 g g g j,k as agreed L690Q or X100Q 0.16 0.45 1.90 0.020 0.010 g g g j,k as agreed Welded pipe L245M or BM 0.22 0.45 1.20 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L290M or X42M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L320M orX46M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360M orX52M 0.22 0.45 1.40 0.025 0.015 d d d e,l 0.43 0.25 L390 or X56M 0.22 0.45 1.40 0.025 0.015 d d d e,l 0.43 0.25 L415 or X60M 0.12 f 0.45 f 1.60 f 0.025 0.015 g g g h,I 0.43 0.25 L450 or X65M 0.12 f 0.45 f 1.60 f 0.025 0.015 g g g h,l 0.43 0.25 L485M or X70M 0.12 f 0.45 f 1.70 f 0.025 0.015 g g g h,l 0.43 0.25 L555M orX80M 0.12 f 0.45 f 1.85 f 0.025 0.015 g g g i,l 0.43 0.25 L625 or X90M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,l 一 0.25 L690M or X100M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,j 0.25 L830M or X120M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,j 0.25 a.Based upon product analysis.For seamless pipe with t>20.0 mm(0.787 in),the CE limits shall be as agreed.

The CEIIW limits apply if C>0.12% and the CEPcm limits apply if C≤0.12%.

b.For each reduction of 0.01% below the specified maximum for C,an increase of 0.05% above the specified maximum for

permissible,up to a maximum of 1.65% for grades ≥L245 or B,but≤L360 or X52;up to a maximum of1.75%for grades>

X52,but<L485 or X70;up to a maximum of 2.00% for grades≥L485 orX70,but≤L555 or X80;and up to a maximum of

grades>L555 or X80.

c.Unless otherwise agreed,Nb+V≤0.06%.

d.Nb+V+Ti≤0.15%

e.Unless otherwise agreed,Cu≤0.50%;Ni≤0.30%;Cr≤0.30%and Mo≤0.15%

f.Unless otherwise agreed.

g.Unless otherwise agreed,Nb+V+Ti≤0.15%.

h.Unless otherwise agreed,Cu≤0.50%;Ni≤0.50%;Cr≤0.50%and Mo≤0.50%.

i.Unless otherwise agreed,Cu≤0.50%;Ni≤1.00%;Cr≤0.50%and Mo≤0.50%

j.B≤0.004%.

k.Unless otherwise agreed,Cu≤0.50%;Ni≤1.00%;Cr≤0.55%and Mo≤0.80%.

1.For all PSL2 pipe grades except those grades to which footnote j already applies,the following applies.

Unless otherwise agreed no intentional addition of B is permitted and residual B≤0.001%.The Basic Chemical Elements In API 5L PSL2 Steel Pipes

1. Carbon (C): Carbon is a key element that affects the strength and hardness of the steel. Higher carbon content generally results in increased strength but can reduce ductility and weldability.

2. Manganese (Mn): Manganese is an alloying element that strengthens steel and improves its hardenability. It also helps to remove impurities and sulfur from the steel. The range for manganese in API 5L PSL2 is typically between 0.45% to 1.4%, which provides a balance between strength and formability.

3. Phosphorus (P): Phosphorus is generally considered an impurity in steel and can lead to brittleness. API 5L PSL2 has a strict limit on phosphorus content (maximum 0.030%), which helps to ensure the ductility and toughness of the steel.

4. Sulfur (S): Similar to phosphorus, sulfur is an impurity that can cause embrittlement. API 5L PSL2 also has a strict limit on sulfur content (maximum 0.030%), which is crucial for maintaining the pipe's toughness and resistance to cracking.

5. Chromium (Cr): Chromium enhances the corrosion resistance of steel, especially at elevated temperatures. It also improves the strength and hardness of the steel. API 5L PSL2 specifies a minimum chromium content, which contributes to the pipe's resistance to corrosion.

6. Nickel (Ni): Nickel is another element that improves the corrosion resistance of steel, particularly in acidic environments. It also increases the toughness of the steel at low temperatures. API 5L PSL2 specifies a minimum nickel content, which is important for pipes that may be exposed to corrosive environments.

7. Molybdenum (Mo): Molybdenum is added to steel to improve its strength and hardness at high temperatures. It also enhances the steel's resistance to wear and creep. The maximum molybdenum content in API 5L PSL2 is specified to balance these properties with the need for weldability.

8. Nitrogen (N): Nitrogen is sometimes added to steel to improve its strength and formability. API 5L PSL2 has a maximum nitrogen content limit, which helps to control the steel's properties and ensure consistent performance.

These elements and their controlled amounts in API 5L PSL2 steel pipes are crucial for achieving the desired balance of strength, ductility, toughness, and corrosion resistance, which are essential for the safe and reliable operation of pipelines in various applications.Mechanical Properties

API5L PSL2 Pipe Mechanical Properties(Tensile Strength,Yield Strength,Elongation)

Pipe grade

Pipe body of seamless and welded pipes

Weld seam of HFW,

SAW and COW pipesYield strength

Tensile strengtha

Ratioa,c

Elongation(on

50 mm or 2 in)Tensile strengthd

Rt0.5

Rm

Rt0.5/Rm

A f

Rm

MPa(psi)

MPa(psi)

%

MPa(psi)

minimum

maximum

minimum

maximum

maximum

minimum

minimum

L245R or BR

L245N or BN

L245Q or BQ

L245M or BM245

(35500)450 e

(65300)e415

(60200)655(95000)

0.93

f

415

(60200)L290R or X42R

L290N or X42N

L290Q or X42Q

L290M or X42M290

(42100)495

(71800)415

(60200)655(95000)

0.93

f

415

(60200)L320N or X46N

L320Q or X46Q

L320M or X46M

320

(46400)

525

(76100)

435

(63100)655(95000)

0.93

f

435

(63100)L360N or X52N

L360Q or X52Q

L360M or X52M

360

(52200)

530

(76900)460

(66700)

760

(110200)0.93

f

460

(66700)L390N or X56N

L390Q or X56Q

L390M or X56M

390

(56600)

545

(79000)

490

(71100)

760

(110200)0.93

f

490

(71100)L415N or X60N

L415Q or X60Q

L415M or X60M415

(60200)565

(81900)520

(75400)760

(110200)0.93

f

520

(75400)L450Q or X65Q

L450M or X65M450

(65300)600

(87000)535

(77600)760

(110200)0.93

f

535

(77600)L485Q or X70Q

L485M or X70M485

(70300)635

(92100)570

(82700)760

(110200)0.93

f

570

(82700)L555Q or X80Q

L555M or X80M555

(80500)705

(102300)625

(90600)825

(119700)0.93

f

625

(90600)L625M or X90M

625

(90600)775

(112400)695

(100800)915

(132700)0.95

f

695

(100800)L625Q or X90Q

625

(90600)775

(112400)695

(100800)915

(132700)0.97 g

f

695

(100800)L690M or X100M

690 b

(100100) b840 b

(121800)760

(110200)990

(143600)0.97h

f

760

(110200)L690Q or X100Q

690 b

(100100) b840 b

(121800)760

(110200)990

(143600)0.97h

f

760

(110200)L830M or X120M

830b

(120400)b1050b

(152300)b915

(132700)1145

(166100)0.99h

f

915

(132700)a. For intermediate grades, the difference between specified maximum yield strength and minimum YS shall be as given in the table for

the next higher grade, and the difference between specified minimum tensile strength and the specified minimum TS shall be as given in

the table for the next higher grade. For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000 psi).

For intermediate grades greater than Grade L320 or X46 and lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psi).

For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units,

the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

b. For grades > L625 or X90, Rp0.2 applies.

c. Above limit applies for pipe with D > 323.9 mm (12.750 in).

d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for

the pipe body using footnote a).

e. For pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 495 MPa (71 800 psi).

f. The specified minimum elongation, Af, shall be as determined with following equation: Af=C×A0.2XC/U0.9

g. Lower values of Rt0.5/Rm may be specified by agreement.

h. For grades > L625 or X90, Rp0.2 /Rm applies. Lower values of Rp0.2 /Rm may be specified by agreement.Significant Of Mechanical Properties

1. Yield Strength (Rt0.5 or Rm): This property indicates the stress level at which the steel begins to deform plastically. Higher yield strength in PSL2 pipes means they can handle greater stresses without permanent deformation, making them suitable for high-pressure applications .

2. Tensile Strength (Rm): This is the maximum stress that the pipe material can withstand before breaking. PSL2 pipes have higher tensile strength compared to PSL1, allowing them to resist higher loads and making them ideal for critical applications where pipe integrity is paramount .

3. Elongation (Af): Elongation measures the percentage of deformation a material can undergo before rupture. PSL2 pipes have stricter elongation requirements, ensuring they can deform under stress without breaking, which is crucial for absorbing impact forces and preventing catastrophic failures .

4. Ratio of Yield to Tensile Strength (Rt0.5/Rm): This ratio is an indicator of the pipe's ductility. PSL2 pipes have a minimum ratio requirement, ensuring a balance between strength and ductility, which is important for withstanding complex stress conditions without failure .

These mechanical properties collectively ensure that API 5L PSL2 pipes provide superior performance, reliability, and safety in the most demanding pipeline applications, including those involving high pressures, high temperatures, and corrosive environments.

Differences Between API5L PSL1 And PSL2

API 5L PSL1 and PSL2 are two different levels of specifications within the API 5L standard for steel pipes used in the oil and gas industry. Here are the key differences between them:(CLICK HERE➡What Are The Differences Between API5L PSL1 And PSL2 Steel Pipe)

Grade Range:

PSL1 covers steel grades from A25 to X70, while PSL2 covers a broader range from Grade B to X120, with some manufacturers capable of producing grades up to X100.Size Range:

PSL1 pipes are available from 0.405" to 80" in diameter, whereas PSL2 pipes range from 4.5" to 80".Type of Pipe Ends:

PSL1 pipes can have various types of ends such as plain end, threaded end, beveled end, or special coupling pipes. PSL2 pipes are typically available only with plain ends unless otherwise agreed.Welding Method:

PSL1 allows all kinds of welding methods, while PSL2 limits the welding methods, excluding continuous welding and laser welding.Chemical Composition:

PSL2 has stricter requirements for chemical composition, with lower maximum limits for carbon and sulfur, which can affect the pipe's strength and corrosion resistance.Mechanical Properties:

PSL2 pipes must meet higher standards for mechanical properties like yield strength and tensile strength, with maximum limits specified for each grade.Test Methods

In summary, PSL1 represents the standard quality level with basic requirements, while PSL2 imposes more stringent criteria for quality control, mechanical properties, and testing procedures, making it suitable for more demanding applications in the oil and gas industry.Test Methods

The API 5L PSL2 pipes have additional testing requirements that are not mandatory for PSL1. These tests are designed to ensure a higher level of quality and suitability for critical applications. Here are the test methods that are required for API 5L PSL2 but not for PSL1:Charpy V-Notch (CVN) Impact Testing at Low Temperatures: This test is used to evaluate the impact resistance of the pipe material at low temperatures, typically down to -40°C (-40°F) or lower, to ensure the pipe's performance in cold climates or during winter operations.

Weldability Testing: This assessment evaluates the ability of the pipe to be welded without affecting its mechanical properties, ensuring the integrity of the welded joints.

Hardness Testing: This test measures the surface hardness of the pipe, which is important for resisting wear, abrasion, and deformation during installation and operation.

Drop Weight Tear Test (DWTT): This test measures the pipe's resistance to brittle fracture, which is crucial for ensuring the pipe's integrity in high-pressure, high-stress applications.

Non-Destructive Testing (NDT): PSL2 requires non-destructive testing of each pipe to ensure the safety and integrity of the pipeline. Specific testing methods may include radiographic testing, ultrasonic testing, etc.

Hydrostatic Testing: PSL2 requires hydrostatic testing of each pipe, and non-destructive testing cannot be used instead of hydrostatic testing.

These additional tests for API 5L PSL2 pipes provide a higher level of assurance regarding the pipe's performance, safety, and suitability for critical applications in the oil and gas industry.

Applications

API 5L PSL2 pipes are designed for critical applications that demand high strength, toughness, and reliability. Here are some of the key applications for API 5L PSL2 pipes:Oil and Gas Industry: API 5L PSL2 pipes are extensively used in the oil and gas industry for the transportation of hydrocarbons and other fluids under high pressures and temperatures. They are essential for onshore and offshore pipeline applications.

Construction Sector: In the construction industry, API 5L PSL2 pipes are used for structural applications such as building frameworks and bridges where strength and durability are crucial.

Water and Sewage Systems: These pipes are utilized in water and sewage systems due to their ability to withstand internal pressure, corrosion, and environmental factors, ensuring efficient water supply and wastewater management.

Energy Sector: API 5L PSL2 pipes are used in energy production and distribution systems, including pipelines for transporting oil, gas, and other energy resources, where operational reliability and safety are paramount.

Automotive Industry: The automotive industry uses API 5L PSL2 pipes for various applications, including vehicle components and exhaust systems, due to their high strength and durability.

Cross-Border and Offshore Pipelines: API 5L PSL2 pipes are often used in cross-border pipelines and offshore pipelines where more mechanical properties like resistance to high pressures and corrosive environments are needed.

These applications highlight the significance of API 5L PSL2 pipes in ensuring the safe and efficient transportation of fluids, gases, and other materials across different sectors. Their use is governed by various industry standards and regulations to ensure safety, performance, and durability.

API5L PSL2 Steel Pipes

Subcategory

Keyword

- Details

-

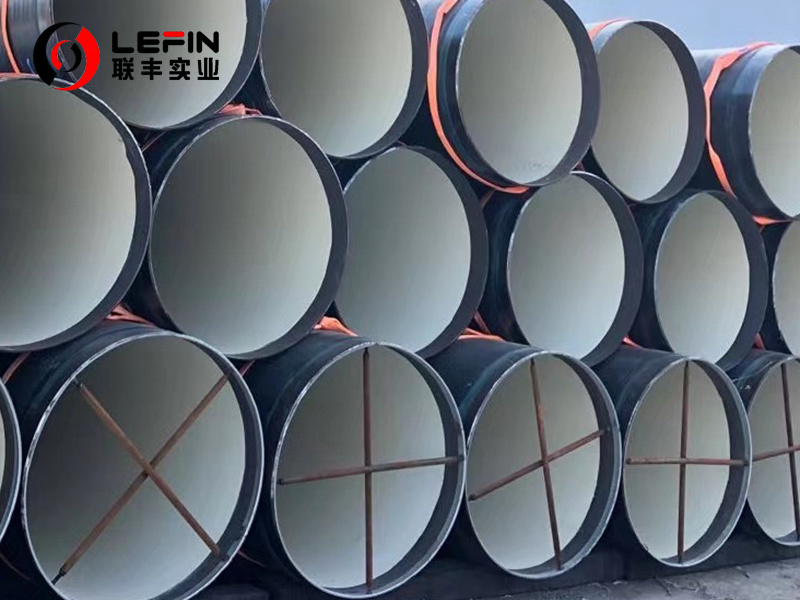

API 5L PSL2

Grades: Grade B, X42, X52, X56, X60, X65, X70, X80

Product Specification Level: PSL1, PSL2, onshore and offshore sour services

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12",16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded),

in LSAW, DSAW, SSAW, HSAW

Ends Type: Beveled ends, Plain ends.

Length Range: SRL (Single Random Length), DRL (Double Random Length) , 20 FT (6 meters), 40FT (12 meters) or, customized.

Protection Caps in plastic or iron.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Chemical Composition

Chemical Composition for API 5L PSL2 Pipe with t≤25.0 mm(0.984 in)

Steel Grade

(Steel Name)Mass fraction,based upon heat and product analyses

Carbon

equivalent%,maximum

%,maximum

C b Si

Mn b

P

S

V

Nb

Ti

Other

CEIIw

CEPcm

Seamless and welded pipes

L245R or BR 0.24 0.40 1.20 0.025 0.015 c c 0.04 e,l 0.43 0.25 L290R or X42R 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,I 0.43 0.25 L245N or BN 0.24 0.40 1.20 0.025 0.015 c c 0.04 e,l 0.43 0.25 L290N or X42N 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,l 0.43 0.25 L320N or X46N 0.24 0.40 1.40 0.025 0.015 0.07 0.05 0.04 d,e,I 0.43 0.25 L360N or X52N 0.24 0.45 1.40 0.025 0.015 0.10 0.05 0.04 d,e,I 0.43 0.25 L390N or X56N 0.24 0.45 1.40 0.025 0.015 0.10 0.05 0.04 d,e,I 0.43 0.25 L415N or X60N 0.24 f 0.45 f 1.40 f 0.025 0.015 0.10 0.05 0.04 g,h,l as agreed L245Qor BQ 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L290Q or X42Q 0.18 0.45 1.40 f 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L320Q or X46Q 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360Q or X52Q 0.18 0.45 1.50 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L390Q or X56Q 0.18 0.45 1.50 0.025 0.015 0.07 0.05 0.04 d,e,I 0.43 0.25 L415Q or X60Q 0.18 f 0.45 f 1.70 f 0.025 0.015 g g g h,l 0.43 0.25 L450Q or X65Q 0.18 f 0.45 f 1.70 f 0.025 0.015 g g g h,I 0.43 0.25 L485Q or X70Q 0.18 f 0.45 f 1.80 f 0.025 0.015 g g g h,l 0.43 0.25 L555Q or X80Q 0.18 f 0.45 f 1.90 f 0.025 0.015 g g g i,j as agreed L625Q or X90Q 0.16 0.45 1.90 0.020 0.010 g g g j,k as agreed L690Q or X100Q 0.16 0.45 1.90 0.020 0.010 g g g j,k as agreed Welded pipe L245M or BM 0.22 0.45 1.20 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L290M or X42M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L320M orX46M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360M orX52M 0.22 0.45 1.40 0.025 0.015 d d d e,l 0.43 0.25 L390 or X56M 0.22 0.45 1.40 0.025 0.015 d d d e,l 0.43 0.25 L415 or X60M 0.12 f 0.45 f 1.60 f 0.025 0.015 g g g h,I 0.43 0.25 L450 or X65M 0.12 f 0.45 f 1.60 f 0.025 0.015 g g g h,l 0.43 0.25 L485M or X70M 0.12 f 0.45 f 1.70 f 0.025 0.015 g g g h,l 0.43 0.25 L555M orX80M 0.12 f 0.45 f 1.85 f 0.025 0.015 g g g i,l 0.43 0.25 L625 or X90M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,l 一 0.25 L690M or X100M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,j 0.25 L830M or X120M 0.10 0.55 f 2.10 f 0.020 0.010 g g g i,j 0.25 a.Based upon product analysis.For seamless pipe with t>20.0 mm(0.787 in),the CE limits shall be as agreed.

The CEIIW limits apply if C>0.12% and the CEPcm limits apply if C≤0.12%.

b.For each reduction of 0.01% below the specified maximum for C,an increase of 0.05% above the specified maximum for

permissible,up to a maximum of 1.65% for grades ≥L245 or B,but≤L360 or X52;up to a maximum of1.75%for grades>

X52,but<L485 or X70;up to a maximum of 2.00% for grades≥L485 orX70,but≤L555 or X80;and up to a maximum of

grades>L555 or X80.

c.Unless otherwise agreed,Nb+V≤0.06%.

d.Nb+V+Ti≤0.15%

e.Unless otherwise agreed,Cu≤0.50%;Ni≤0.30%;Cr≤0.30%and Mo≤0.15%

f.Unless otherwise agreed.

g.Unless otherwise agreed,Nb+V+Ti≤0.15%.

h.Unless otherwise agreed,Cu≤0.50%;Ni≤0.50%;Cr≤0.50%and Mo≤0.50%.

i.Unless otherwise agreed,Cu≤0.50%;Ni≤1.00%;Cr≤0.50%and Mo≤0.50%

j.B≤0.004%.

k.Unless otherwise agreed,Cu≤0.50%;Ni≤1.00%;Cr≤0.55%and Mo≤0.80%.

1.For all PSL2 pipe grades except those grades to which footnote j already applies,the following applies.

Unless otherwise agreed no intentional addition of B is permitted and residual B≤0.001%.The Basic Chemical Elements In API 5L PSL2 Steel Pipes

1. Carbon (C): Carbon is a key element that affects the strength and hardness of the steel. Higher carbon content generally results in increased strength but can reduce ductility and weldability.

2. Manganese (Mn): Manganese is an alloying element that strengthens steel and improves its hardenability. It also helps to remove impurities and sulfur from the steel. The range for manganese in API 5L PSL2 is typically between 0.45% to 1.4%, which provides a balance between strength and formability.

3. Phosphorus (P): Phosphorus is generally considered an impurity in steel and can lead to brittleness. API 5L PSL2 has a strict limit on phosphorus content (maximum 0.030%), which helps to ensure the ductility and toughness of the steel.

4. Sulfur (S): Similar to phosphorus, sulfur is an impurity that can cause embrittlement. API 5L PSL2 also has a strict limit on sulfur content (maximum 0.030%), which is crucial for maintaining the pipe's toughness and resistance to cracking.

5. Chromium (Cr): Chromium enhances the corrosion resistance of steel, especially at elevated temperatures. It also improves the strength and hardness of the steel. API 5L PSL2 specifies a minimum chromium content, which contributes to the pipe's resistance to corrosion.

6. Nickel (Ni): Nickel is another element that improves the corrosion resistance of steel, particularly in acidic environments. It also increases the toughness of the steel at low temperatures. API 5L PSL2 specifies a minimum nickel content, which is important for pipes that may be exposed to corrosive environments.

7. Molybdenum (Mo): Molybdenum is added to steel to improve its strength and hardness at high temperatures. It also enhances the steel's resistance to wear and creep. The maximum molybdenum content in API 5L PSL2 is specified to balance these properties with the need for weldability.

8. Nitrogen (N): Nitrogen is sometimes added to steel to improve its strength and formability. API 5L PSL2 has a maximum nitrogen content limit, which helps to control the steel's properties and ensure consistent performance.

These elements and their controlled amounts in API 5L PSL2 steel pipes are crucial for achieving the desired balance of strength, ductility, toughness, and corrosion resistance, which are essential for the safe and reliable operation of pipelines in various applications.Mechanical Properties

API5L PSL2 Pipe Mechanical Properties(Tensile Strength,Yield Strength,Elongation)

Pipe grade

Pipe body of seamless and welded pipes

Weld seam of HFW,

SAW and COW pipesYield strength

Tensile strengtha

Ratioa,c

Elongation(on

50 mm or 2 in)Tensile strengthd

Rt0.5

Rm

Rt0.5/Rm

A f

Rm

MPa(psi)

MPa(psi)

%

MPa(psi)

minimum

maximum

minimum

maximum

maximum

minimum

minimum

L245R or BR

L245N or BN

L245Q or BQ

L245M or BM245

(35500)450 e

(65300)e415

(60200)655(95000)

0.93

f

415

(60200)L290R or X42R

L290N or X42N

L290Q or X42Q

L290M or X42M290

(42100)495

(71800)415

(60200)655(95000)

0.93

f

415

(60200)L320N or X46N

L320Q or X46Q

L320M or X46M

320

(46400)

525

(76100)

435

(63100)655(95000)

0.93

f

435

(63100)L360N or X52N

L360Q or X52Q

L360M or X52M

360

(52200)

530

(76900)460

(66700)

760

(110200)0.93

f

460

(66700)L390N or X56N

L390Q or X56Q

L390M or X56M

390

(56600)

545

(79000)

490

(71100)

760

(110200)0.93

f

490

(71100)L415N or X60N

L415Q or X60Q

L415M or X60M415

(60200)565

(81900)520

(75400)760

(110200)0.93

f

520

(75400)L450Q or X65Q

L450M or X65M450

(65300)600

(87000)535

(77600)760

(110200)0.93

f

535

(77600)L485Q or X70Q

L485M or X70M485

(70300)635

(92100)570

(82700)760

(110200)0.93

f

570

(82700)L555Q or X80Q

L555M or X80M555

(80500)705

(102300)625

(90600)825

(119700)0.93

f

625

(90600)L625M or X90M

625

(90600)775

(112400)695

(100800)915

(132700)0.95

f

695

(100800)L625Q or X90Q

625

(90600)775

(112400)695

(100800)915

(132700)0.97 g

f

695

(100800)L690M or X100M

690 b

(100100) b840 b

(121800)760

(110200)990

(143600)0.97h

f

760

(110200)L690Q or X100Q

690 b

(100100) b840 b

(121800)760

(110200)990

(143600)0.97h

f

760

(110200)L830M or X120M

830b

(120400)b1050b

(152300)b915

(132700)1145

(166100)0.99h

f

915

(132700)a. For intermediate grades, the difference between specified maximum yield strength and minimum YS shall be as given in the table for

the next higher grade, and the difference between specified minimum tensile strength and the specified minimum TS shall be as given in

the table for the next higher grade. For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000 psi).

For intermediate grades greater than Grade L320 or X46 and lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psi).

For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units,

the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

b. For grades > L625 or X90, Rp0.2 applies.

c. Above limit applies for pipe with D > 323.9 mm (12.750 in).

d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for

the pipe body using footnote a).

e. For pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 495 MPa (71 800 psi).

f. The specified minimum elongation, Af, shall be as determined with following equation: Af=C×A0.2XC/U0.9

g. Lower values of Rt0.5/Rm may be specified by agreement.

h. For grades > L625 or X90, Rp0.2 /Rm applies. Lower values of Rp0.2 /Rm may be specified by agreement.Significant Of Mechanical Properties

1. Yield Strength (Rt0.5 or Rm): This property indicates the stress level at which the steel begins to deform plastically. Higher yield strength in PSL2 pipes means they can handle greater stresses without permanent deformation, making them suitable for high-pressure applications .

2. Tensile Strength (Rm): This is the maximum stress that the pipe material can withstand before breaking. PSL2 pipes have higher tensile strength compared to PSL1, allowing them to resist higher loads and making them ideal for critical applications where pipe integrity is paramount .

3. Elongation (Af): Elongation measures the percentage of deformation a material can undergo before rupture. PSL2 pipes have stricter elongation requirements, ensuring they can deform under stress without breaking, which is crucial for absorbing impact forces and preventing catastrophic failures .

4. Ratio of Yield to Tensile Strength (Rt0.5/Rm): This ratio is an indicator of the pipe's ductility. PSL2 pipes have a minimum ratio requirement, ensuring a balance between strength and ductility, which is important for withstanding complex stress conditions without failure .

These mechanical properties collectively ensure that API 5L PSL2 pipes provide superior performance, reliability, and safety in the most demanding pipeline applications, including those involving high pressures, high temperatures, and corrosive environments.

Differences Between API5L PSL1 And PSL2

API 5L PSL1 and PSL2 are two different levels of specifications within the API 5L standard for steel pipes used in the oil and gas industry. Here are the key differences between them:(CLICK HERE➡What Are The Differences Between API5L PSL1 And PSL2 Steel Pipe)

Grade Range:

PSL1 covers steel grades from A25 to X70, while PSL2 covers a broader range from Grade B to X120, with some manufacturers capable of producing grades up to X100.Size Range:

PSL1 pipes are available from 0.405" to 80" in diameter, whereas PSL2 pipes range from 4.5" to 80".Type of Pipe Ends:

PSL1 pipes can have various types of ends such as plain end, threaded end, beveled end, or special coupling pipes. PSL2 pipes are typically available only with plain ends unless otherwise agreed.Welding Method:

PSL1 allows all kinds of welding methods, while PSL2 limits the welding methods, excluding continuous welding and laser welding.Chemical Composition:

PSL2 has stricter requirements for chemical composition, with lower maximum limits for carbon and sulfur, which can affect the pipe's strength and corrosion resistance.Mechanical Properties:

PSL2 pipes must meet higher standards for mechanical properties like yield strength and tensile strength, with maximum limits specified for each grade.Test Methods

In summary, PSL1 represents the standard quality level with basic requirements, while PSL2 imposes more stringent criteria for quality control, mechanical properties, and testing procedures, making it suitable for more demanding applications in the oil and gas industry.Test Methods

The API 5L PSL2 pipes have additional testing requirements that are not mandatory for PSL1. These tests are designed to ensure a higher level of quality and suitability for critical applications. Here are the test methods that are required for API 5L PSL2 but not for PSL1:Charpy V-Notch (CVN) Impact Testing at Low Temperatures: This test is used to evaluate the impact resistance of the pipe material at low temperatures, typically down to -40°C (-40°F) or lower, to ensure the pipe's performance in cold climates or during winter operations.

Weldability Testing: This assessment evaluates the ability of the pipe to be welded without affecting its mechanical properties, ensuring the integrity of the welded joints.

Hardness Testing: This test measures the surface hardness of the pipe, which is important for resisting wear, abrasion, and deformation during installation and operation.

Drop Weight Tear Test (DWTT): This test measures the pipe's resistance to brittle fracture, which is crucial for ensuring the pipe's integrity in high-pressure, high-stress applications.

Non-Destructive Testing (NDT): PSL2 requires non-destructive testing of each pipe to ensure the safety and integrity of the pipeline. Specific testing methods may include radiographic testing, ultrasonic testing, etc.

Hydrostatic Testing: PSL2 requires hydrostatic testing of each pipe, and non-destructive testing cannot be used instead of hydrostatic testing.

These additional tests for API 5L PSL2 pipes provide a higher level of assurance regarding the pipe's performance, safety, and suitability for critical applications in the oil and gas industry.

Applications

API 5L PSL2 pipes are designed for critical applications that demand high strength, toughness, and reliability. Here are some of the key applications for API 5L PSL2 pipes:Oil and Gas Industry: API 5L PSL2 pipes are extensively used in the oil and gas industry for the transportation of hydrocarbons and other fluids under high pressures and temperatures. They are essential for onshore and offshore pipeline applications.

Construction Sector: In the construction industry, API 5L PSL2 pipes are used for structural applications such as building frameworks and bridges where strength and durability are crucial.

Water and Sewage Systems: These pipes are utilized in water and sewage systems due to their ability to withstand internal pressure, corrosion, and environmental factors, ensuring efficient water supply and wastewater management.

Energy Sector: API 5L PSL2 pipes are used in energy production and distribution systems, including pipelines for transporting oil, gas, and other energy resources, where operational reliability and safety are paramount.

Automotive Industry: The automotive industry uses API 5L PSL2 pipes for various applications, including vehicle components and exhaust systems, due to their high strength and durability.

Cross-Border and Offshore Pipelines: API 5L PSL2 pipes are often used in cross-border pipelines and offshore pipelines where more mechanical properties like resistance to high pressures and corrosive environments are needed.

These applications highlight the significance of API 5L PSL2 pipes in ensuring the safe and efficient transportation of fluids, gases, and other materials across different sectors. Their use is governed by various industry standards and regulations to ensure safety, performance, and durability.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn