- Details

-

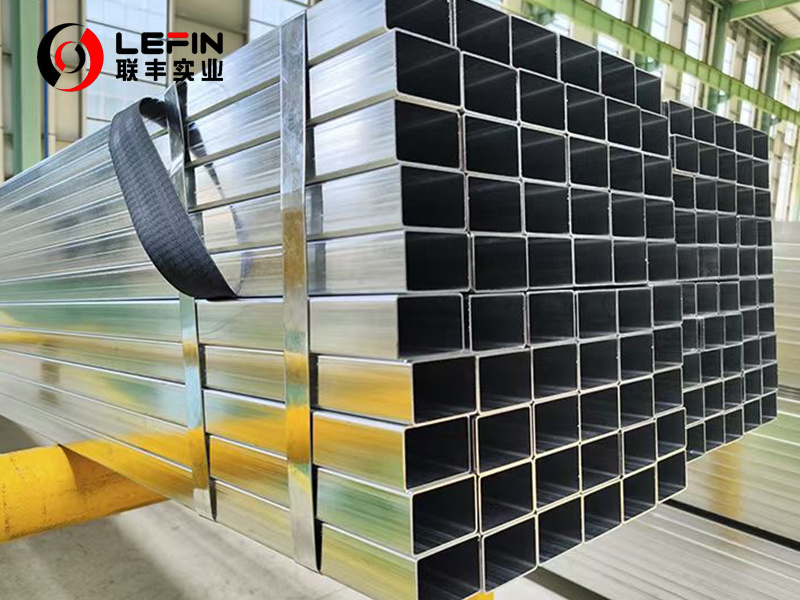

Standard EN 10255, whose full name is "Technical Delivery Conditions for Welded and Non-Alloy Steel Threaded Pipes and Smooth End Pipes", mainly stipulates the dimensions, tolerances and technical requirements of circular cross-section welded steel pipes used in piping systems.

When it is combined with "galvanized hollow steel sections", it usually refers to welded steel pipes that meet this standard and have undergone hot-dip galvanizing treatment, which are often used for structural support rather than fluid transportation.

The following table summarizes the core information of EN 10255 galvanized hollow steel sections to help you understand it quickly.

Project Explanation Product form Welded steel pipes with circular cross-sections are usually hollow Common standards EN 10255 (for the steel pipe itself), the galvanizing process may refer to other standards (such as ISO-related standards) Typical galvanizing process Hot-dip galvanizing usually has a galvanized coating thickness of no less than 35μm, and can reach 200μm when high protection requirements are met Common materials Non-alloy steel (such as S235JR grades, etc.) Main features Strong corrosion resistance, high structural strength, long service life, and uniform specifications for easy design and construction Typical application scenarios Building structure frames, greenhouse sheds, heavy-duty shelves, guardrails, cable trays, support structures for mechanical equipment, etc 💡 Key points of use and construction

In order to ensure that the performance of EN 10255 galvanized hollow steel sections is fully exerted, the following points should be noted during construction and use:

Process hole design:For closed or semi-closed components that require hot-dip galvanizing, process holes must be reasonably set. This is to ensure that the zinc liquid can flow in smoothly and the air can be discharged smoothly, thereby obtaining a complete and uniform coating. The diameter of the process holes is generally recommended to be no less than 15 millimeters and should be set at the highest and lowest points of the component.

Connection method:Besides the traditional welding and bolt connection, for the construction of frame structures, dedicated connection parts (such as corner codes, bases, etc.) are often used for assembly. This method is fast, adjustable, and does not damage the galvanized layer.

On-site cutting and welding protection:If on-site cutting or welding is required, it will cause damage to the galvanized coating in the cut or weld area. It is essential to carry out anti-corrosion repairs on these areas, such as using zinc-rich primer and special galvanized touch-up paint for strict treatment; otherwise, rusting will start from here.

Storage and handling:During storage and handling, care should be taken to avoid severe scratches on the surface galvanized layer to prevent affecting its anti-corrosion performance.

💎 Summary

EN 10255 galvanized hollow steel section is a structural material with both good mechanical properties and excellent corrosion resistance. It is particularly suitable for occasions where there are high requirements for durability, structural stability and anti-corrosion ability.

EN 10255 GALVANIZED HOLLOW SECTIONS

Subcategory

Keyword

- Details

-

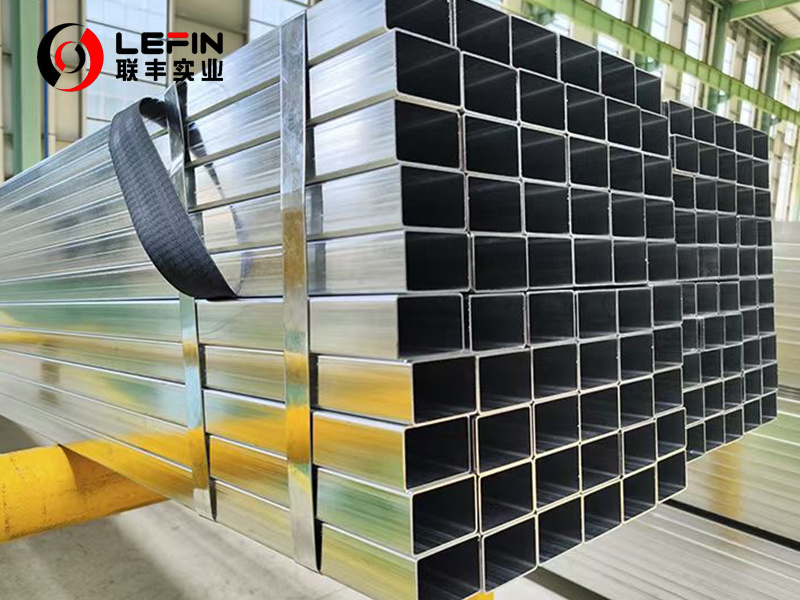

Standard EN 10255, whose full name is "Technical Delivery Conditions for Welded and Non-Alloy Steel Threaded Pipes and Smooth End Pipes", mainly stipulates the dimensions, tolerances and technical requirements of circular cross-section welded steel pipes used in piping systems.

When it is combined with "galvanized hollow steel sections", it usually refers to welded steel pipes that meet this standard and have undergone hot-dip galvanizing treatment, which are often used for structural support rather than fluid transportation.

The following table summarizes the core information of EN 10255 galvanized hollow steel sections to help you understand it quickly.

Project Explanation Product form Welded steel pipes with circular cross-sections are usually hollow Common standards EN 10255 (for the steel pipe itself), the galvanizing process may refer to other standards (such as ISO-related standards) Typical galvanizing process Hot-dip galvanizing usually has a galvanized coating thickness of no less than 35μm, and can reach 200μm when high protection requirements are met Common materials Non-alloy steel (such as S235JR grades, etc.) Main features Strong corrosion resistance, high structural strength, long service life, and uniform specifications for easy design and construction Typical application scenarios Building structure frames, greenhouse sheds, heavy-duty shelves, guardrails, cable trays, support structures for mechanical equipment, etc 💡 Key points of use and construction

In order to ensure that the performance of EN 10255 galvanized hollow steel sections is fully exerted, the following points should be noted during construction and use:

Process hole design:For closed or semi-closed components that require hot-dip galvanizing, process holes must be reasonably set. This is to ensure that the zinc liquid can flow in smoothly and the air can be discharged smoothly, thereby obtaining a complete and uniform coating. The diameter of the process holes is generally recommended to be no less than 15 millimeters and should be set at the highest and lowest points of the component.

Connection method:Besides the traditional welding and bolt connection, for the construction of frame structures, dedicated connection parts (such as corner codes, bases, etc.) are often used for assembly. This method is fast, adjustable, and does not damage the galvanized layer.

On-site cutting and welding protection:If on-site cutting or welding is required, it will cause damage to the galvanized coating in the cut or weld area. It is essential to carry out anti-corrosion repairs on these areas, such as using zinc-rich primer and special galvanized touch-up paint for strict treatment; otherwise, rusting will start from here.

Storage and handling:During storage and handling, care should be taken to avoid severe scratches on the surface galvanized layer to prevent affecting its anti-corrosion performance.

💎 Summary

EN 10255 galvanized hollow steel section is a structural material with both good mechanical properties and excellent corrosion resistance. It is particularly suitable for occasions where there are high requirements for durability, structural stability and anti-corrosion ability.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn