- Details

-

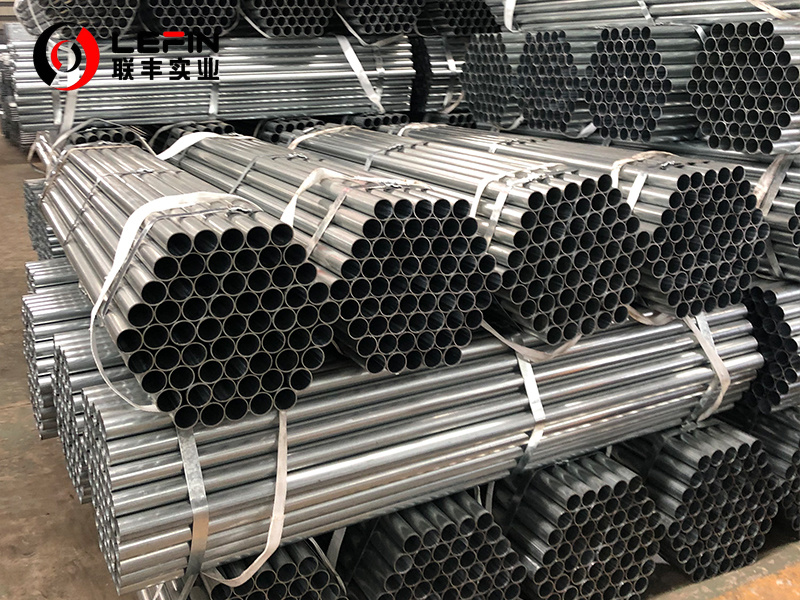

ASTM A123 is the core standard for hot-dip galvanized coatings of steel products, which is particularly crucial for galvanized steel pipes. The following table can help you quickly grasp the key points of ASTM A123 galvanized steel pipes in terms of standard requirements, unique features and main applications.

Category Key points Core requirements of the standard Process: Hot-dip galvanizing; Zinc coating thickness: According to the thickness classification requirements of steel (for example, for steel pipes, it is usually 45-75μm);

Zinc purity: ≥98% Quality inspection: There are strict regulations on thickness, uniformity and adhesion

Unique feature/

Advantage:

Excellent corrosion resistance;

The zinc-iron alloy layer is firmly bonded and has high hardness.

It has the cathodic protection effect of a "sacrificial anode".

Comprehensive protection, including the interiors of complex components

Typical application fields Including building structures (frames, guardrails, scaffolding);

Infrastructure (plumbing and heating works, fire protection systems);

Transportation (component manufacturing)

Agriculture (greenhouses, irrigation systems)

🏗️The specific requirements of standard

ASTM A123 standard has clear and detailed regulations on the process of hot-dip galvanizing, coating quality, materials used and testing methods.

• Process and zinc coating characteristics:

The standard requires the use of hot-dip galvanizing process. The galvanized layer formed is not a single pure zinc layer, but an alloy layer structure composed of the Gamma layer, Delta layer, Zeta layer and the outermost Eta layer (pure zinc layer) formed successively from the base steel to the outside. These alloy layers have different iron contents, and their hardness is even higher than that of the base steel. Therefore, the coating is wear-resistant and has good adhesion. The standard also requires that the average zinc content of the molten metal in the galvanizing bath be no less than 98% (by weight percentage), and allows the addition of trace amounts of elements such as aluminum and nickel to improve the appearance and processability of the coating.

• Zinc coating thickness:

The standard stipulates the corresponding minimum average coating thickness requirements based on the material category (such as structural steel, steel plates, steel strips, bars, steel pipes, wire rods, etc.) and the thickness of the steel. For instance, for "steel pipes and pipe products", the minimum average coating thickness requirement varies depending on the thickness of the steel, typically ranging from 45 microns to 75 microns. The standard also has strict regulations on sampling, the number of measurement points (usually no less than 5 points on one sample), and the calculation of average values.

• Quality and Inspection:

The galvanized coating should be continuous and uniform. Minor roughness related to the chemical composition or reaction of the base steel is allowed, but there should be no obvious defects that affect usage. The standard also includes requirements and methods for the adhesion of the coating (such as hammering tests) and the repair of missed coating damage (which must be carried out in accordance with the A780 standard, with a limited repair area). The standard stipulates that products with a surface area greater than 160 square inches need to be sampled and tested in different zones.

💡 Unique product advantages

The galvanized steel pipes produced based on the ASTM A123 standard have the following main advantages:

• Outstanding corrosion resistance and long-lasting protection:

The hot-dip galvanized coating first acts as a physical barrier, isolating the steel substrate from the corrosive environment. More importantly, when the coating is damaged, zinc will act as a "sacrificial anode" and corrode preferentially, thereby protecting the internal steel. This cathodic protection effect is not available in many other coatings. The corrosion rate of the zinc coating in the atmosphere is extremely slow, approximately 1/17 to 1/18 of that of steel, which gives galvanized steel pipes a very long service life.

• Comprehensive and robust protective coating:

The hot-dip galvanizing process enables zinc liquid to penetrate every corner of the pipe, even providing a uniform protective coating on the inner walls and recesses. The coverage integrity is usually superior to that of manual painting. The zinc-iron alloy layer formed during the galvanizing process has high hardness and good wear resistance.

• Balancing economic benefits and reliability:

Although the initial cost may be slightly higher, galvanized steel pipes require almost no maintenance throughout their long service life, and the cost-effectiveness throughout their entire life cycle is remarkable. In addition, galvanizing treatment is a strict quality control process carried out in professional factories, and the quality of its coating is reliable and stable.

🏗️ Applications

ASTM A123 galvanized steel pipes are widely used in many important fields due to their excellent corrosion resistance and strong durability.

• Architecture and Structure:

Commonly used in the structural frames of buildings, stair railings, road guardrails, scaffolding, etc. In these application scenarios, steel pipes need to be exposed to the atmosphere for a long time, and good corrosion resistance is of vital importance.

• Infrastructure and public utilities:

Commonly used in plumbing projects (such as water supply pipes), fire protection systems, and cable protection pipes in the power and telecommunications fields. Its corrosion resistance ensures the safety of water supply and the reliability of the system.

• Industry and Agriculture:

In the oil and gas industry, it can be used for transporting oil and gas. In the agricultural field, it is widely used in irrigation systems, the framework structure of greenhouse sheds, and the manufacturing of agricultural machinery.

ASTM A123 GI STEEL PIPE

Subcategory

Keyword

- Details

-

ASTM A123 is the core standard for hot-dip galvanized coatings of steel products, which is particularly crucial for galvanized steel pipes. The following table can help you quickly grasp the key points of ASTM A123 galvanized steel pipes in terms of standard requirements, unique features and main applications.

Category Key points Core requirements of the standard Process: Hot-dip galvanizing; Zinc coating thickness: According to the thickness classification requirements of steel (for example, for steel pipes, it is usually 45-75μm);

Zinc purity: ≥98% Quality inspection: There are strict regulations on thickness, uniformity and adhesion

Unique feature/

Advantage:

Excellent corrosion resistance;

The zinc-iron alloy layer is firmly bonded and has high hardness.

It has the cathodic protection effect of a "sacrificial anode".

Comprehensive protection, including the interiors of complex components

Typical application fields Including building structures (frames, guardrails, scaffolding);

Infrastructure (plumbing and heating works, fire protection systems);

Transportation (component manufacturing)

Agriculture (greenhouses, irrigation systems)

🏗️The specific requirements of standard

ASTM A123 standard has clear and detailed regulations on the process of hot-dip galvanizing, coating quality, materials used and testing methods.

• Process and zinc coating characteristics:

The standard requires the use of hot-dip galvanizing process. The galvanized layer formed is not a single pure zinc layer, but an alloy layer structure composed of the Gamma layer, Delta layer, Zeta layer and the outermost Eta layer (pure zinc layer) formed successively from the base steel to the outside. These alloy layers have different iron contents, and their hardness is even higher than that of the base steel. Therefore, the coating is wear-resistant and has good adhesion. The standard also requires that the average zinc content of the molten metal in the galvanizing bath be no less than 98% (by weight percentage), and allows the addition of trace amounts of elements such as aluminum and nickel to improve the appearance and processability of the coating.

• Zinc coating thickness:

The standard stipulates the corresponding minimum average coating thickness requirements based on the material category (such as structural steel, steel plates, steel strips, bars, steel pipes, wire rods, etc.) and the thickness of the steel. For instance, for "steel pipes and pipe products", the minimum average coating thickness requirement varies depending on the thickness of the steel, typically ranging from 45 microns to 75 microns. The standard also has strict regulations on sampling, the number of measurement points (usually no less than 5 points on one sample), and the calculation of average values.

• Quality and Inspection:

The galvanized coating should be continuous and uniform. Minor roughness related to the chemical composition or reaction of the base steel is allowed, but there should be no obvious defects that affect usage. The standard also includes requirements and methods for the adhesion of the coating (such as hammering tests) and the repair of missed coating damage (which must be carried out in accordance with the A780 standard, with a limited repair area). The standard stipulates that products with a surface area greater than 160 square inches need to be sampled and tested in different zones.

💡 Unique product advantages

The galvanized steel pipes produced based on the ASTM A123 standard have the following main advantages:

• Outstanding corrosion resistance and long-lasting protection:

The hot-dip galvanized coating first acts as a physical barrier, isolating the steel substrate from the corrosive environment. More importantly, when the coating is damaged, zinc will act as a "sacrificial anode" and corrode preferentially, thereby protecting the internal steel. This cathodic protection effect is not available in many other coatings. The corrosion rate of the zinc coating in the atmosphere is extremely slow, approximately 1/17 to 1/18 of that of steel, which gives galvanized steel pipes a very long service life.

• Comprehensive and robust protective coating:

The hot-dip galvanizing process enables zinc liquid to penetrate every corner of the pipe, even providing a uniform protective coating on the inner walls and recesses. The coverage integrity is usually superior to that of manual painting. The zinc-iron alloy layer formed during the galvanizing process has high hardness and good wear resistance.

• Balancing economic benefits and reliability:

Although the initial cost may be slightly higher, galvanized steel pipes require almost no maintenance throughout their long service life, and the cost-effectiveness throughout their entire life cycle is remarkable. In addition, galvanizing treatment is a strict quality control process carried out in professional factories, and the quality of its coating is reliable and stable.

🏗️ Applications

ASTM A123 galvanized steel pipes are widely used in many important fields due to their excellent corrosion resistance and strong durability.

• Architecture and Structure:

Commonly used in the structural frames of buildings, stair railings, road guardrails, scaffolding, etc. In these application scenarios, steel pipes need to be exposed to the atmosphere for a long time, and good corrosion resistance is of vital importance.

• Infrastructure and public utilities:

Commonly used in plumbing projects (such as water supply pipes), fire protection systems, and cable protection pipes in the power and telecommunications fields. Its corrosion resistance ensures the safety of water supply and the reliability of the system.

• Industry and Agriculture:

In the oil and gas industry, it can be used for transporting oil and gas. In the agricultural field, it is widely used in irrigation systems, the framework structure of greenhouse sheds, and the manufacturing of agricultural machinery.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn