- Details

-

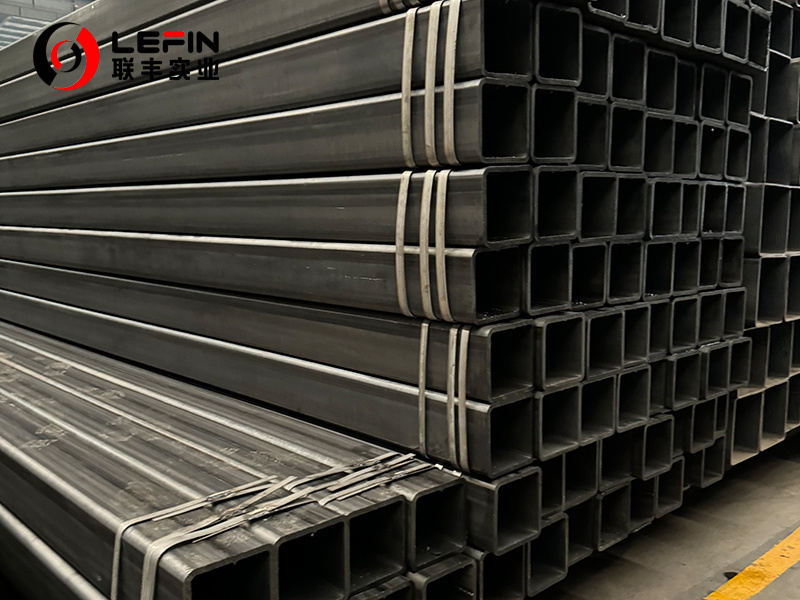

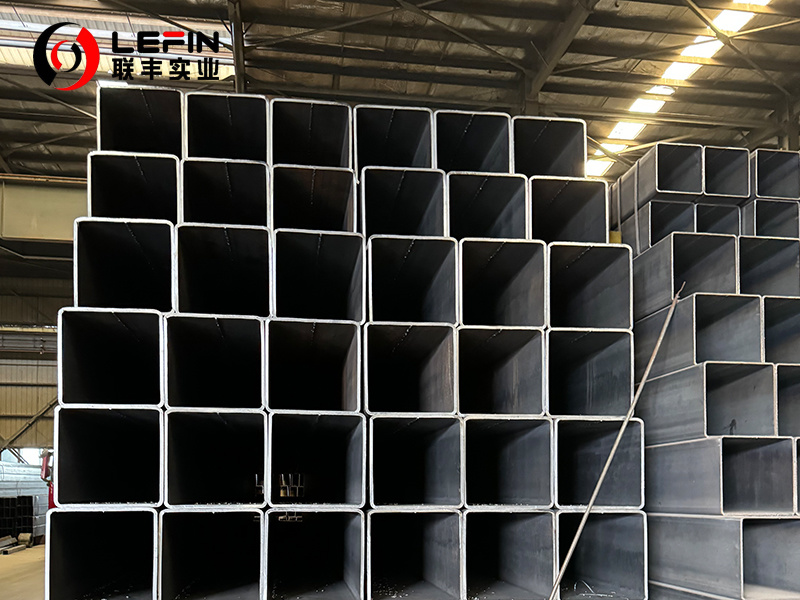

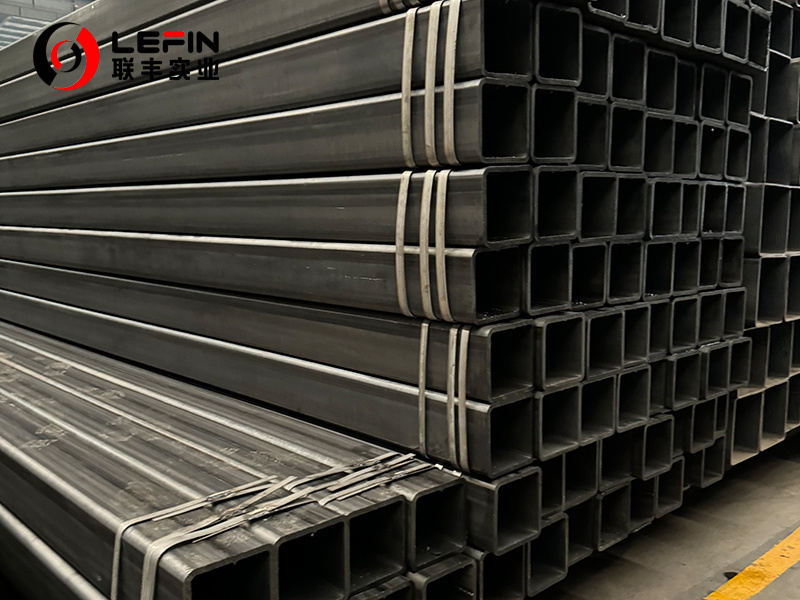

EN10025 GI pipes combine steel that complies with the European structural steel standard EN10025 with a galvanizing (GI) protection process, making them a widely used material in construction, engineering and other fields.

The main features of each division of the EN10025 standard

Standard division Core Content Typical steel grade examples Applicable product forms

EN 10025-1 General Technical Delivery conditions are the general outline for all divisions. - Hot-rolled flat and long products (excluding structural hollow profiles and tubes). EN 10025-2 Non-alloy structural steel, with good weldability and formability S235JR, S275JR, and S355JR Hot-rolled products EN 10025-3 Normalized/Normalized rolled weldable fine-grained structural steel, with superior toughness S275N, S275NL, S355N and S355NL Hot-rolled products EN 10025-4 Hot mechanical rolling weldable fine-grained structural steel, high strength obtained through controlled rolling and controlled cooling. S355M, S355ML Hot-rolled products EN 10025-5 Improved atmospheric corrosion-resistant structural steel (weathering steel), suitable for exposed environments. S235J0W and S355J2W Hot-rolled products EN 10025-6 High yield strength structural steel in quenched and tempered state, with the highest strength grade. S460Q, S690QL Flat rolled materials (steel plates and thin plates). 💡 How to choose EN10025 GI pipe

When facing EN10025 GI pipes of different specifications, you can consider the following aspects to make an appropriate choice:

- Clarify the application scenarios:

First, determine the main purpose of the pipeline. Is it used for building structures, mechanical manufacturing, or for transporting fluids such as water and gas? Different applications have different emphases on the strength, toughness, corrosion resistance and weldability of pipes.

- Assess the usage environment:

What kind of environment will the pipeline be in? Indoor or outdoor? Have you come into contact with corrosive media or been in a high-humidity environment? This is directly related to how much corrosion-resistant galvanized coating you need and whether you need to consider weathering steel as stipulated in EN10025-5.

- Determine mechanical property requirements:

Based on the design load, determine the minimum yield strength (such as S235, S355, S460, etc.) and toughness indicators (such as impact energy requirements for JR, J0, J2, etc.) of the required pipeline.

- Consider the processing technology:

Does the pipe require subsequent processing such as bending and welding? This requires you to pay attention to the carbon equivalent (CEV) of the steel to ensure good weldability and its formability.

EN10025 GI PIPE combines the EN10025 structural steel standard with the Galvanized Iron (GI) anti-corrosion process and is a type of steel widely used in construction, engineering and other fields.

Project Specific requirements or common options Material standard EN 10025-2 (such as S235JR, S275JR, S355JR) Galvanized type Pre-galvanized, zinc coating weight Z40-80g/m²;

Or Hot-dip galvanized, with a zinc coating weight of Z200-600g/m²

Common specification Outside diameter: 1/2 inch - 24 inches (approximately 21.3mm - 610mm);

Wall thickness: 0.4mm - 12mm or SCH10s-XS;

Length: 1m - 12m or customized

Mechanical properties It is necessary to meet the requirements of EN10025 for the corresponding steel grades (such as yield strength and tensile strength) End processing Plain, bevel, Threaded Chief application Building structures, fluid transportation (water, gas), mechanical manufacturing, and agricultural greenhouses 🔧 Understand the technical requirements

The core of EN10025 GI PIPE lies in simultaneously meeting the requirements of material performance and anti-corrosion performance.

- Regarding the EN10025 standard:

EN10025 is a European standard for structural steel, covering multiple sections. The commonly used materials for GI Pipe are non-alloy structural steels in EN 10025-2, such as S235JR, S275JR, and S355JR. These grades have good strength and solderability. The standard clearly stipulates the chemical composition of steel (such as carbon equivalent CEV, which affects weldability) and mechanical properties (such as yield strength ReH, tensile strength Rm, elongation).

- Regarding galvanization (GI) :

The galvanized coating is the key to anti-corrosion. There are mainly two ways:

- Pre-galvanized: Pipes are directly rolled and welded from galvanized steel strips. The zinc coating is usually thin, about 40 to 80 grams per square meter.

- Hot-dip galvanized: Galvanizing black pipes by immersing them in molten zinc. The zinc coating is relatively thick, usually 200 to 600 grams per square meter, which has stronger anti-corrosion ability and is more durable.

- Other technical details:

For pipes, attention should also be paid to dimensional tolerances, end treatment methods (such as flat ends, bevels for welding, or threaded connections), as well as possible quality inspections such as water pressure tests or eddy current tests.

Main application fields

EN10025 GI PIPE is widely used in: Due to its structural strength and corrosion resistance

- Architecture and Structural Engineering:

Commonly used in steel frame structures of factories and warehouses, auxiliary components of Bridges, roof trusses, construction scaffolding and guardrails, etc.

- Fluid transportation:

It is used for transporting fluids such as water, gas, and low-pressure steam, and is commonly found in fire protection pipelines, municipal water supply networks, etc.

- In the field of mechanical manufacturing and industry:

It serves as the casing, bracket, and component of the conveying system for mechanical equipment, and is also used in the structure of certain equipment in chemical plants and the mining industry.

- Agriculture and horticulture:

Commonly used as the frame structure for building greenhouse sheds.

Other uses: It can also be seen in substation facilities, traffic sign poles, street lamp poles, etc.

⚠️ Purchase and use notes

When choosing and using EN10025 GI PIPE, there are several points that need special attention:

1. Clarify requirements:

Select the appropriate zinc coating thickness of the galvanizing type based on the corrosiveness of the usage environment (indoor, outdoor, humid or chemical environment). Select the appropriate strength grade (such as S235JR, S355JR) and wall thickness of the pipe according to the load requirements of the structural design.

2. Pay attention to weldability:If welding is required, pay attention to the carbon equivalent (CEV) of the steel. A high CEV value may affect the welding performance and increase the risk of cracking.

3. Check quality documents:When purchasing, request the Material Certificate (MTC) from the supplier to ensure that the product complies with the EN10025 standard and the required galvanized coating requirements. A third-party inspection may be requested when necessary.

4. Storage and Installation:Try to avoid bumps and damages to the zinc coating. If the zinc coating is scratched, it should be repaired in time with special zinc-rich anti-corrosion paint to maintain the overall anti-corrosion effect.

💎 summary

EN10025 GI PIPE is a steel product that combines performance and anti-corrosion ability, and is suitable for various occasions where structural strength and durability are required.

EN 10255 GI PIPE

Subcategory

Keyword

- Details

-

EN10025 GI pipes combine steel that complies with the European structural steel standard EN10025 with a galvanizing (GI) protection process, making them a widely used material in construction, engineering and other fields.

The main features of each division of the EN10025 standard

Standard division Core Content Typical steel grade examples Applicable product forms

EN 10025-1 General Technical Delivery conditions are the general outline for all divisions. - Hot-rolled flat and long products (excluding structural hollow profiles and tubes). EN 10025-2 Non-alloy structural steel, with good weldability and formability S235JR, S275JR, and S355JR Hot-rolled products EN 10025-3 Normalized/Normalized rolled weldable fine-grained structural steel, with superior toughness S275N, S275NL, S355N and S355NL Hot-rolled products EN 10025-4 Hot mechanical rolling weldable fine-grained structural steel, high strength obtained through controlled rolling and controlled cooling. S355M, S355ML Hot-rolled products EN 10025-5 Improved atmospheric corrosion-resistant structural steel (weathering steel), suitable for exposed environments. S235J0W and S355J2W Hot-rolled products EN 10025-6 High yield strength structural steel in quenched and tempered state, with the highest strength grade. S460Q, S690QL Flat rolled materials (steel plates and thin plates). 💡 How to choose EN10025 GI pipe

When facing EN10025 GI pipes of different specifications, you can consider the following aspects to make an appropriate choice:

- Clarify the application scenarios:

First, determine the main purpose of the pipeline. Is it used for building structures, mechanical manufacturing, or for transporting fluids such as water and gas? Different applications have different emphases on the strength, toughness, corrosion resistance and weldability of pipes.

- Assess the usage environment:

What kind of environment will the pipeline be in? Indoor or outdoor? Have you come into contact with corrosive media or been in a high-humidity environment? This is directly related to how much corrosion-resistant galvanized coating you need and whether you need to consider weathering steel as stipulated in EN10025-5.

- Determine mechanical property requirements:

Based on the design load, determine the minimum yield strength (such as S235, S355, S460, etc.) and toughness indicators (such as impact energy requirements for JR, J0, J2, etc.) of the required pipeline.

- Consider the processing technology:

Does the pipe require subsequent processing such as bending and welding? This requires you to pay attention to the carbon equivalent (CEV) of the steel to ensure good weldability and its formability.

EN10025 GI PIPE combines the EN10025 structural steel standard with the Galvanized Iron (GI) anti-corrosion process and is a type of steel widely used in construction, engineering and other fields.

Project Specific requirements or common options Material standard EN 10025-2 (such as S235JR, S275JR, S355JR) Galvanized type Pre-galvanized, zinc coating weight Z40-80g/m²;

Or Hot-dip galvanized, with a zinc coating weight of Z200-600g/m²

Common specification Outside diameter: 1/2 inch - 24 inches (approximately 21.3mm - 610mm);

Wall thickness: 0.4mm - 12mm or SCH10s-XS;

Length: 1m - 12m or customized

Mechanical properties It is necessary to meet the requirements of EN10025 for the corresponding steel grades (such as yield strength and tensile strength) End processing Plain, bevel, Threaded Chief application Building structures, fluid transportation (water, gas), mechanical manufacturing, and agricultural greenhouses 🔧 Understand the technical requirements

The core of EN10025 GI PIPE lies in simultaneously meeting the requirements of material performance and anti-corrosion performance.

- Regarding the EN10025 standard:

EN10025 is a European standard for structural steel, covering multiple sections. The commonly used materials for GI Pipe are non-alloy structural steels in EN 10025-2, such as S235JR, S275JR, and S355JR. These grades have good strength and solderability. The standard clearly stipulates the chemical composition of steel (such as carbon equivalent CEV, which affects weldability) and mechanical properties (such as yield strength ReH, tensile strength Rm, elongation).

- Regarding galvanization (GI) :

The galvanized coating is the key to anti-corrosion. There are mainly two ways:

- Pre-galvanized: Pipes are directly rolled and welded from galvanized steel strips. The zinc coating is usually thin, about 40 to 80 grams per square meter.

- Hot-dip galvanized: Galvanizing black pipes by immersing them in molten zinc. The zinc coating is relatively thick, usually 200 to 600 grams per square meter, which has stronger anti-corrosion ability and is more durable.

- Other technical details:

For pipes, attention should also be paid to dimensional tolerances, end treatment methods (such as flat ends, bevels for welding, or threaded connections), as well as possible quality inspections such as water pressure tests or eddy current tests.

Main application fields

EN10025 GI PIPE is widely used in: Due to its structural strength and corrosion resistance

- Architecture and Structural Engineering:

Commonly used in steel frame structures of factories and warehouses, auxiliary components of Bridges, roof trusses, construction scaffolding and guardrails, etc.

- Fluid transportation:

It is used for transporting fluids such as water, gas, and low-pressure steam, and is commonly found in fire protection pipelines, municipal water supply networks, etc.

- In the field of mechanical manufacturing and industry:

It serves as the casing, bracket, and component of the conveying system for mechanical equipment, and is also used in the structure of certain equipment in chemical plants and the mining industry.

- Agriculture and horticulture:

Commonly used as the frame structure for building greenhouse sheds.

Other uses: It can also be seen in substation facilities, traffic sign poles, street lamp poles, etc.

⚠️ Purchase and use notes

When choosing and using EN10025 GI PIPE, there are several points that need special attention:

1. Clarify requirements:

Select the appropriate zinc coating thickness of the galvanizing type based on the corrosiveness of the usage environment (indoor, outdoor, humid or chemical environment). Select the appropriate strength grade (such as S235JR, S355JR) and wall thickness of the pipe according to the load requirements of the structural design.

2. Pay attention to weldability:If welding is required, pay attention to the carbon equivalent (CEV) of the steel. A high CEV value may affect the welding performance and increase the risk of cracking.

3. Check quality documents:When purchasing, request the Material Certificate (MTC) from the supplier to ensure that the product complies with the EN10025 standard and the required galvanized coating requirements. A third-party inspection may be requested when necessary.

4. Storage and Installation:Try to avoid bumps and damages to the zinc coating. If the zinc coating is scratched, it should be repaired in time with special zinc-rich anti-corrosion paint to maintain the overall anti-corrosion effect.

💎 summary

EN10025 GI PIPE is a steel product that combines performance and anti-corrosion ability, and is suitable for various occasions where structural strength and durability are required.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn