- Details

-

Manufacturing of steel pipe base

Hot-dip galvanized steel pipes first require the production of the steel pipe base (black pipe), mainly using the welded pipe process.- Forming: The coiled steel strip is unrolled and leveled, and then gradually rolled into a round tube shape through a series of rolling dies.

- Welding:The edges of the formed steel pipes are longitudinally welded through techniques such as high-frequency resistance welding to form a sealed pipe body. Welding quality is of vital importance and must comply with strict specifications (such as the WPS welding procedure specifications).

Pretreatment before galvanizing

This is the most crucial step to ensure the quality of galvanizing. The aim is to make the surface of the steel pipe reach a "clean and activated" state, ensuring that the zinc layer can adhere firmly:

- Degreasing: Use alkaline degreasing solution or specific chemical solutions (such as degreasing solution containing phospholipids, fatty acid glycerides) to remove oil stains, lubricants and other organic contaminants on the surface of steel pipes.

- Pickling: Immerse the steel pipe in a hydrochloric acid solution (with a concentration typically ranging from 18% to 30%) to remove rust and oxide scale from the surface. Sometimes, acid solutions of different concentrations are used for segmented treatment to enhance the effect.

- Rinsing: Rinse with clean water to thoroughly remove any remaining acid and reaction products (iron salts).

- Flux treatment: Immerse the washed steel pipes in a mixed solution of ammonium chloride and zinc chloride as a flux. This can form a protective film on the surface of the steel pipe, preventing re-oxidation and enhancing the wetting ability of the zinc liquid on the steel substrate.

- Drying: Dry the steel pipes coated with flux at 100°C - 200°C to prevent zinc liquid splashing due to rapid evaporation of water when immersed in the zinc pot.

Core link of hot-dip galvanizing

The steel pipes that have undergone pretreatment enter the core galvanizing stage:Hot-dip galvanizing:

- Steel pipes are immersed in molten zinc liquid with a temperature strictly controlled between 440°C and 460°C. The impregnation time is determined by the specifications of the steel pipe and the required thickness of the zinc coating, usually ranging from a few seconds to several minutes. During this process, iron and zinc undergo a diffusion reaction, forming a strong zinc-iron alloy layer.

Zinc coating control:

- When the steel pipe leaves the zinc bath, a "circular air knife" (injecting compressed air or nitrogen) is used for purging, or the thickness of the pure zinc coating is controlled and the surface is made uniform and smooth by wiping methods such as steel wire, asbestos clamps, and charcoal.

Post-plating treatment and inspection

After the steel pipes are taken out of the furnace, they still need to undergo subsequent processing to ensure the quality of the final product.Cooling:

- After galvanization, the steel pipes will be rapidly cooled. Usually, they are first blown clean by a fan and then enter a water tank for water cooling. Rapid cooling can fix the structure of the zinc layer and prevent the alloy layer from growing excessively and becoming brittle.

Passivation:

- After cooling, the steel pipe is immersed in or sprayed with passivation solution (such as chromate solution or environmentally friendly passivation solution containing molybdenum sulfate, sodium silicate and other components) to form a denser protective film on the surface of the zinc layer, further enhancing its corrosion resistance.

Inspection and packaging:

- Finally, the steel pipes are inspected for the thickness, uniformity, adhesion and surface quality of the zinc coating. Qualified products are printed with marks and then packaged before leaving the factory.

Performance advantages and applications

The hot-dip galvanized steel pipes obtained through the above-mentioned complex process have a zinc-iron alloy layer that is firmly bonded to the steel pipe base, providing long-lasting anti-corrosion protection (with a service life of up to 50 years under standard conditions), and have low maintenance costs.This makes it widely applied in:

- In the field of architecture: used as roof supports, building frames and fencing.

- Public utilities: Used for clean water delivery, gas pipelines (Note: There is a trend of replacement in some fields), and fire protection systems.

- In the industrial field: It is used as a pipe network in industrial environments such as chemical engineering and mining, as well as pipes in HVAC (Heating, Ventilation and Air Conditioning) systems.

- Protective purpose: As a protective sleeve for wires and cables.

It is hoped that this detailed interpretation can help you have a comprehensive understanding of the manufacturing process of hot-dip galvanized steel pipes. If you have further interest in a specific aspect or the differences among various standards, I would be more than happy to provide you with more information.

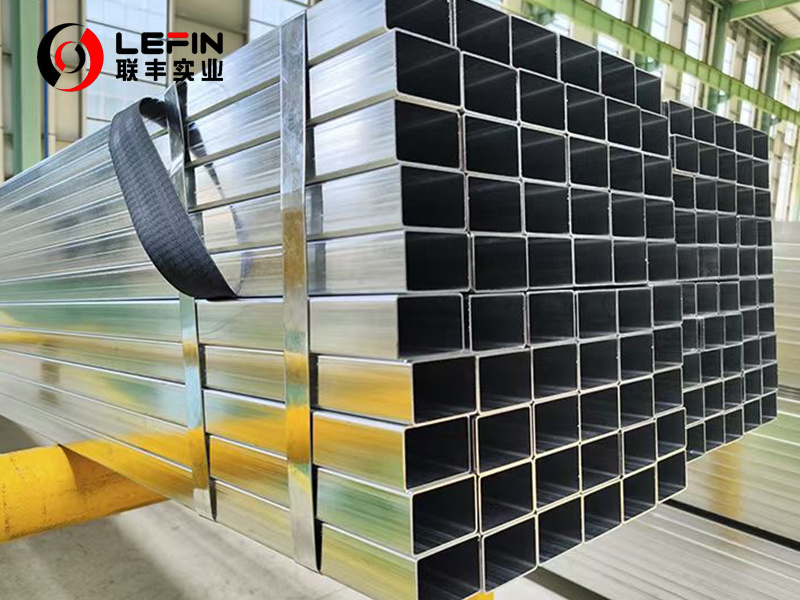

HOT DIP GALVANIZED STEEL PIPE

Subcategory

Keyword

- Details

-

Manufacturing of steel pipe base

Hot-dip galvanized steel pipes first require the production of the steel pipe base (black pipe), mainly using the welded pipe process.- Forming: The coiled steel strip is unrolled and leveled, and then gradually rolled into a round tube shape through a series of rolling dies.

- Welding:The edges of the formed steel pipes are longitudinally welded through techniques such as high-frequency resistance welding to form a sealed pipe body. Welding quality is of vital importance and must comply with strict specifications (such as the WPS welding procedure specifications).

Pretreatment before galvanizing

This is the most crucial step to ensure the quality of galvanizing. The aim is to make the surface of the steel pipe reach a "clean and activated" state, ensuring that the zinc layer can adhere firmly:

- Degreasing: Use alkaline degreasing solution or specific chemical solutions (such as degreasing solution containing phospholipids, fatty acid glycerides) to remove oil stains, lubricants and other organic contaminants on the surface of steel pipes.

- Pickling: Immerse the steel pipe in a hydrochloric acid solution (with a concentration typically ranging from 18% to 30%) to remove rust and oxide scale from the surface. Sometimes, acid solutions of different concentrations are used for segmented treatment to enhance the effect.

- Rinsing: Rinse with clean water to thoroughly remove any remaining acid and reaction products (iron salts).

- Flux treatment: Immerse the washed steel pipes in a mixed solution of ammonium chloride and zinc chloride as a flux. This can form a protective film on the surface of the steel pipe, preventing re-oxidation and enhancing the wetting ability of the zinc liquid on the steel substrate.

- Drying: Dry the steel pipes coated with flux at 100°C - 200°C to prevent zinc liquid splashing due to rapid evaporation of water when immersed in the zinc pot.

Core link of hot-dip galvanizing

The steel pipes that have undergone pretreatment enter the core galvanizing stage:Hot-dip galvanizing:

- Steel pipes are immersed in molten zinc liquid with a temperature strictly controlled between 440°C and 460°C. The impregnation time is determined by the specifications of the steel pipe and the required thickness of the zinc coating, usually ranging from a few seconds to several minutes. During this process, iron and zinc undergo a diffusion reaction, forming a strong zinc-iron alloy layer.

Zinc coating control:

- When the steel pipe leaves the zinc bath, a "circular air knife" (injecting compressed air or nitrogen) is used for purging, or the thickness of the pure zinc coating is controlled and the surface is made uniform and smooth by wiping methods such as steel wire, asbestos clamps, and charcoal.

Post-plating treatment and inspection

After the steel pipes are taken out of the furnace, they still need to undergo subsequent processing to ensure the quality of the final product.Cooling:

- After galvanization, the steel pipes will be rapidly cooled. Usually, they are first blown clean by a fan and then enter a water tank for water cooling. Rapid cooling can fix the structure of the zinc layer and prevent the alloy layer from growing excessively and becoming brittle.

Passivation:

- After cooling, the steel pipe is immersed in or sprayed with passivation solution (such as chromate solution or environmentally friendly passivation solution containing molybdenum sulfate, sodium silicate and other components) to form a denser protective film on the surface of the zinc layer, further enhancing its corrosion resistance.

Inspection and packaging:

- Finally, the steel pipes are inspected for the thickness, uniformity, adhesion and surface quality of the zinc coating. Qualified products are printed with marks and then packaged before leaving the factory.

Performance advantages and applications

The hot-dip galvanized steel pipes obtained through the above-mentioned complex process have a zinc-iron alloy layer that is firmly bonded to the steel pipe base, providing long-lasting anti-corrosion protection (with a service life of up to 50 years under standard conditions), and have low maintenance costs.This makes it widely applied in:

- In the field of architecture: used as roof supports, building frames and fencing.

- Public utilities: Used for clean water delivery, gas pipelines (Note: There is a trend of replacement in some fields), and fire protection systems.

- In the industrial field: It is used as a pipe network in industrial environments such as chemical engineering and mining, as well as pipes in HVAC (Heating, Ventilation and Air Conditioning) systems.

- Protective purpose: As a protective sleeve for wires and cables.

It is hoped that this detailed interpretation can help you have a comprehensive understanding of the manufacturing process of hot-dip galvanized steel pipes. If you have further interest in a specific aspect or the differences among various standards, I would be more than happy to provide you with more information.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn