- Details

-

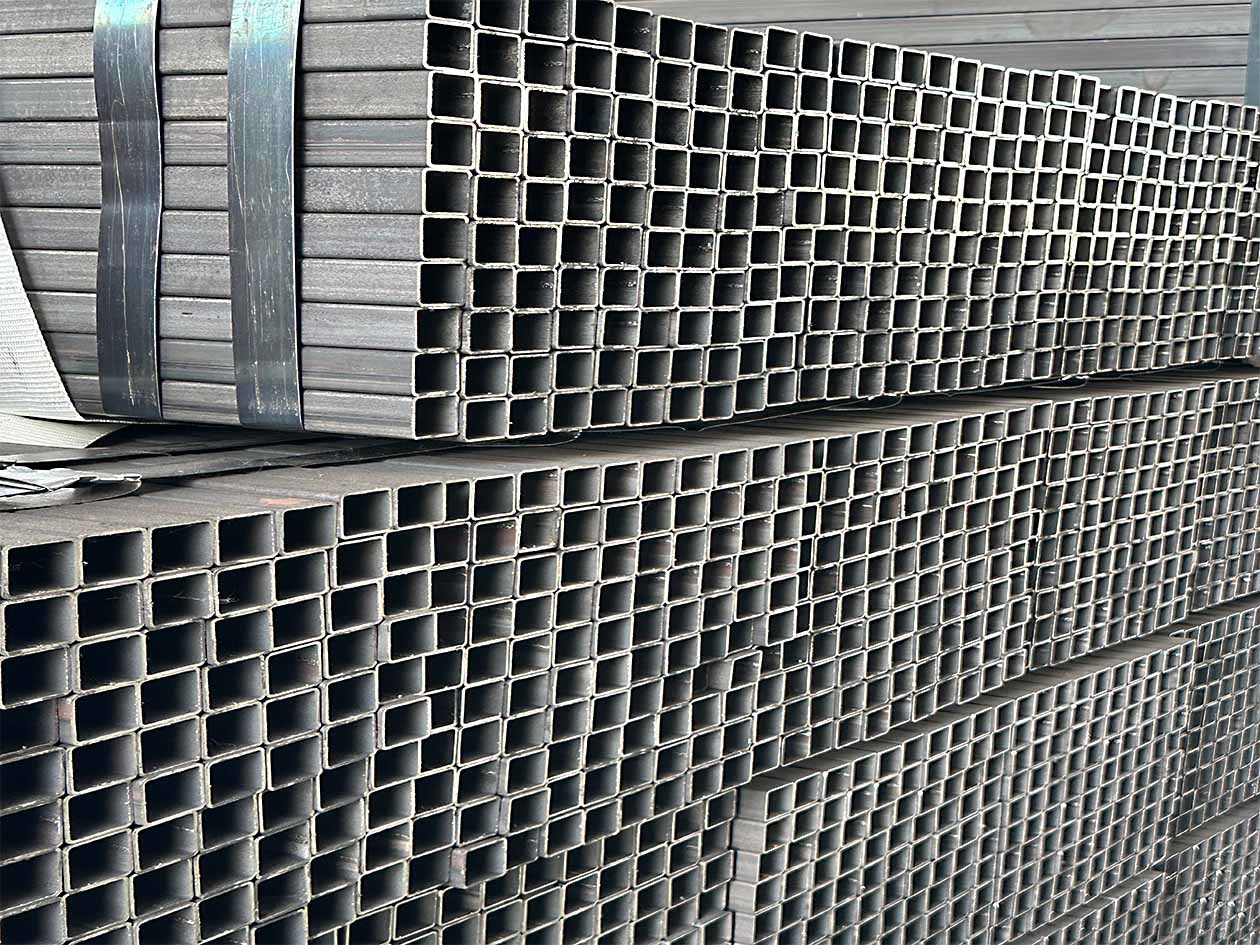

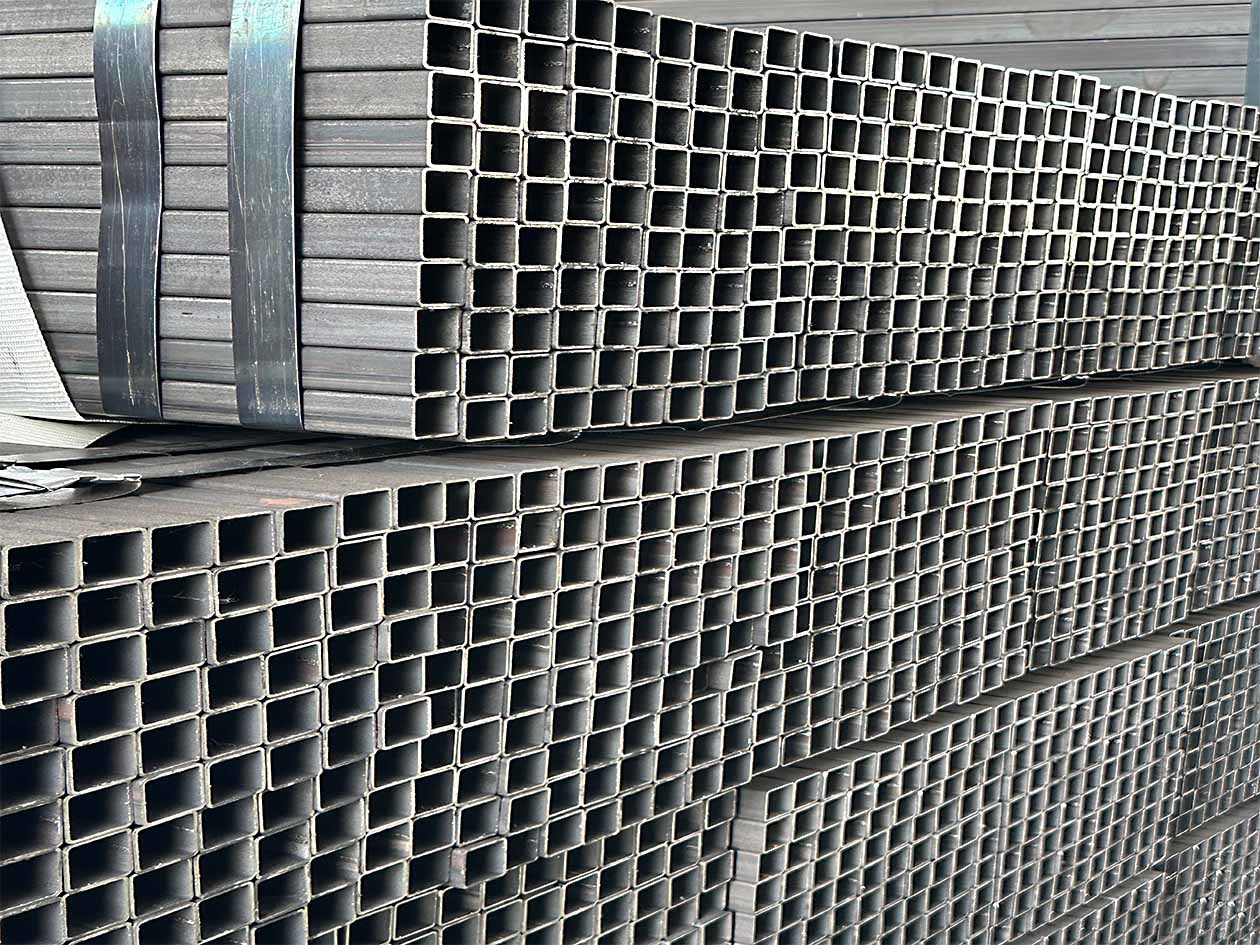

JIS G3101 SS400 is a very common Japanese standard for carbon structural steel, which stipulates the technical requirements of SS400 steel. Although the standard name is "Rolled Steels", steel that meets the chemical composition and mechanical properties requirements of this standard (including SS400) is often used to make pipes.

I. Standards and material requirements

JIS G3101 is a Japanese industrial standard for rolled steel used in general structures. SS400 is a grade under this standard. Among them, "SS" stands for "General Structure Usage Steel", and "400" indicates that its minimum tensile strength is 400 mpa (but the actual specified value is slightly different, see below).

1. Chemical composition requirements:

The requirements for chemical composition of SS400 are relatively lenient, with a greater emphasis on ensuring mechanical properties. Its typical range of chemical compositions is as follows:Carbon (C) ≤ 0.17% Silicon (Si) ≤ 0.5% Manganese (Mn) ≤ 1.4% Phosphorus (P) ≤ 0.035% Sulfur (S) ≤ 0.035% This relatively low carbon content and specific element ratio endow it with excellent weldability and formability.

2. Mechanical performance requirements:

This is the core requirement of SS400, and its mechanical performance must meet the following standards:Yield Strength ≥ 235 MPa Tensile Strength 340-470 MPa Elongation ≥ 24% (depending on the sample specification) 3. Dimensions and Shape:

JIS G3101 itself mainly stipulates the material of steel. The dimensions, shapes and allowable deviations of its specific products (such as steel plates, section steel, bar steel, etc.) need to refer to other corresponding JIS product standards.For example, if it is a steel pipe, its manufacturing and dimensional tolerances will follow the relevant JIS standards for steel pipes (such as JIS G3466, etc.).

For a more intuitive comparison of its main performance indicators, please refer to the table below:

Attribute categories Specific requirements scope remarks Chemical composition Carbon (C) ≤ 0.17% - Silicon (Si) ≤ 0.5% - Manganese (Mn) ≤ 1.4% - Phosphorus (P) ≤ 0.035% - Sulfur (S) ≤ 0.035% - Mechanical properties Yield strength ≥ 235 MPa - Tensile strength 340-470 MPa - Elongation ≥ 24% is determined by the specification of the sample II. Main application fields

Thanks to its excellent comprehensive performance, weldability and relatively low cost, SS400 steel is widely used in various structural and mechanical manufacturing fields.

• Architecture and civil Engineering:

This is the most traditional application field of SS400. It is often used to manufacture steel frame structures, trusses, beams, columns, support components, etc. for high-rise buildings, factory workshops, Bridges, etc.

• Mechanical manufacturing:

It is used for manufacturing various mechanical components, equipment frames, shells, bases, etc. that do not require high strength performance.

• Vehicles and Transportation:

Manufacturing of chassis frames, structural components for automobiles and motorcycles, as well as containers.

• Piping system:

Although JIS G3101 itself is not a dedicated standard for piping, SS400 steel plates and strips are often used to manufacture welded steel pipes (such as ERW welded pipes) for transporting low-pressure fluids like water, gas, and oil, and are widely applied in building water pipes, structural pipes, guardrails, etc.

• Other fields:

It is also commonly used in power transmission towers, internal structures of ships, boilers and non-pressure vessels, as well as various Angle steels, channel steels, H-beams and other profiles.

III. Selection and usage precautions

When choosing and using products made of SS400 material, there are several points that need special attention:

1.The conceptual difference between "Pipe" and "Tube" :

In the standard systems of Europe, America and Japan, "Pipe" and "Tube" often differ.

Pipe (piping) :

Generally refers to the pipe used for transporting fluids. Its specifications are usually indicated by the nominal diameter (NPS) and wall thickness series (Sch.), with more emphasis on the inner diameter and conveying capacity. Pipes made of SS400 fall into this category.

Tube (pipe material) :

Generally refers to a tubular object used for structural support, heat exchange (such as boiler tubes), etc. Its specifications are usually indicated by precise outer diameter and wall thickness, with more emphasis on dimensional accuracy and mechanical properties.

This is a concept that needs to be clarified when ordering and reading standards.

2. Product Form and Processing:

SS400 not only refers to steel pipes but also a type of steel material. It can be rolled into various shapes, such as steel plates, flat steel, round steel, square steel, Angle steel, H-beams, etc. Steel pipes are just one form of its downstream products.

3. Welding performance:

Due to its low carbon equivalent, SS400 usually has good welding performance. However, it is still necessary to follow the appropriate welding process specifications, especially in cold environments or when welding thick plates, to prevent cracks.

4. Corrosion resistance:

SS400 is a carbon steel and does not have the same corrosion resistance as stainless steel. When used in damp or corrosive environments, anti-corrosion measures such as coating and galvanizing need to be taken.

5. Standard Equivalence and Substitution:

In different countries or regions, materials with similar performance to SS400 are often sought.

Europe: S235JR is a common equivalent material. The United States: ASTM A36 is a common approximate material. Although the performance is similar, there may be subtle differences in specific chemical composition and inspection requirements. When substituting, relevant standards should be carefully checked.

IV. Summary

JIS G3101 SS400 is a carbon structural steel with good comprehensive performance and economic practicality. Its quality is ensured by controlling its mechanical properties rather than chemical composition. Due to its moderate strength, excellent welding and forming capabilities, it is widely used in multiple fields ranging from construction and Bridges to mechanical vehicles.

Although JIS G3101 itself is not a special standard for pipes, SS400 steel pipes made of it play an important role in the fields of low-pressure fluid transportation and structural pipes. As long as its non-corrosion-resistant property is noted and appropriate protective measures are taken, it can play a reliable role in various occasions.

JIS 3101 SS400 PIPE

Subcategory

Keyword

- Details

-

JIS G3101 SS400 is a very common Japanese standard for carbon structural steel, which stipulates the technical requirements of SS400 steel. Although the standard name is "Rolled Steels", steel that meets the chemical composition and mechanical properties requirements of this standard (including SS400) is often used to make pipes.

I. Standards and material requirements

JIS G3101 is a Japanese industrial standard for rolled steel used in general structures. SS400 is a grade under this standard. Among them, "SS" stands for "General Structure Usage Steel", and "400" indicates that its minimum tensile strength is 400 mpa (but the actual specified value is slightly different, see below).

1. Chemical composition requirements:

The requirements for chemical composition of SS400 are relatively lenient, with a greater emphasis on ensuring mechanical properties. Its typical range of chemical compositions is as follows:Carbon (C) ≤ 0.17% Silicon (Si) ≤ 0.5% Manganese (Mn) ≤ 1.4% Phosphorus (P) ≤ 0.035% Sulfur (S) ≤ 0.035% This relatively low carbon content and specific element ratio endow it with excellent weldability and formability.

2. Mechanical performance requirements:

This is the core requirement of SS400, and its mechanical performance must meet the following standards:Yield Strength ≥ 235 MPa Tensile Strength 340-470 MPa Elongation ≥ 24% (depending on the sample specification) 3. Dimensions and Shape:

JIS G3101 itself mainly stipulates the material of steel. The dimensions, shapes and allowable deviations of its specific products (such as steel plates, section steel, bar steel, etc.) need to refer to other corresponding JIS product standards.For example, if it is a steel pipe, its manufacturing and dimensional tolerances will follow the relevant JIS standards for steel pipes (such as JIS G3466, etc.).

For a more intuitive comparison of its main performance indicators, please refer to the table below:

Attribute categories Specific requirements scope remarks Chemical composition Carbon (C) ≤ 0.17% - Silicon (Si) ≤ 0.5% - Manganese (Mn) ≤ 1.4% - Phosphorus (P) ≤ 0.035% - Sulfur (S) ≤ 0.035% - Mechanical properties Yield strength ≥ 235 MPa - Tensile strength 340-470 MPa - Elongation ≥ 24% is determined by the specification of the sample II. Main application fields

Thanks to its excellent comprehensive performance, weldability and relatively low cost, SS400 steel is widely used in various structural and mechanical manufacturing fields.

• Architecture and civil Engineering:

This is the most traditional application field of SS400. It is often used to manufacture steel frame structures, trusses, beams, columns, support components, etc. for high-rise buildings, factory workshops, Bridges, etc.

• Mechanical manufacturing:

It is used for manufacturing various mechanical components, equipment frames, shells, bases, etc. that do not require high strength performance.

• Vehicles and Transportation:

Manufacturing of chassis frames, structural components for automobiles and motorcycles, as well as containers.

• Piping system:

Although JIS G3101 itself is not a dedicated standard for piping, SS400 steel plates and strips are often used to manufacture welded steel pipes (such as ERW welded pipes) for transporting low-pressure fluids like water, gas, and oil, and are widely applied in building water pipes, structural pipes, guardrails, etc.

• Other fields:

It is also commonly used in power transmission towers, internal structures of ships, boilers and non-pressure vessels, as well as various Angle steels, channel steels, H-beams and other profiles.

III. Selection and usage precautions

When choosing and using products made of SS400 material, there are several points that need special attention:

1.The conceptual difference between "Pipe" and "Tube" :

In the standard systems of Europe, America and Japan, "Pipe" and "Tube" often differ.

Pipe (piping) :

Generally refers to the pipe used for transporting fluids. Its specifications are usually indicated by the nominal diameter (NPS) and wall thickness series (Sch.), with more emphasis on the inner diameter and conveying capacity. Pipes made of SS400 fall into this category.

Tube (pipe material) :

Generally refers to a tubular object used for structural support, heat exchange (such as boiler tubes), etc. Its specifications are usually indicated by precise outer diameter and wall thickness, with more emphasis on dimensional accuracy and mechanical properties.

This is a concept that needs to be clarified when ordering and reading standards.

2. Product Form and Processing:

SS400 not only refers to steel pipes but also a type of steel material. It can be rolled into various shapes, such as steel plates, flat steel, round steel, square steel, Angle steel, H-beams, etc. Steel pipes are just one form of its downstream products.

3. Welding performance:

Due to its low carbon equivalent, SS400 usually has good welding performance. However, it is still necessary to follow the appropriate welding process specifications, especially in cold environments or when welding thick plates, to prevent cracks.

4. Corrosion resistance:

SS400 is a carbon steel and does not have the same corrosion resistance as stainless steel. When used in damp or corrosive environments, anti-corrosion measures such as coating and galvanizing need to be taken.

5. Standard Equivalence and Substitution:

In different countries or regions, materials with similar performance to SS400 are often sought.

Europe: S235JR is a common equivalent material. The United States: ASTM A36 is a common approximate material. Although the performance is similar, there may be subtle differences in specific chemical composition and inspection requirements. When substituting, relevant standards should be carefully checked.

IV. Summary

JIS G3101 SS400 is a carbon structural steel with good comprehensive performance and economic practicality. Its quality is ensured by controlling its mechanical properties rather than chemical composition. Due to its moderate strength, excellent welding and forming capabilities, it is widely used in multiple fields ranging from construction and Bridges to mechanical vehicles.

Although JIS G3101 itself is not a special standard for pipes, SS400 steel pipes made of it play an important role in the fields of low-pressure fluid transportation and structural pipes. As long as its non-corrosion-resistant property is noted and appropriate protective measures are taken, it can play a reliable role in various occasions.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn