- Details

-

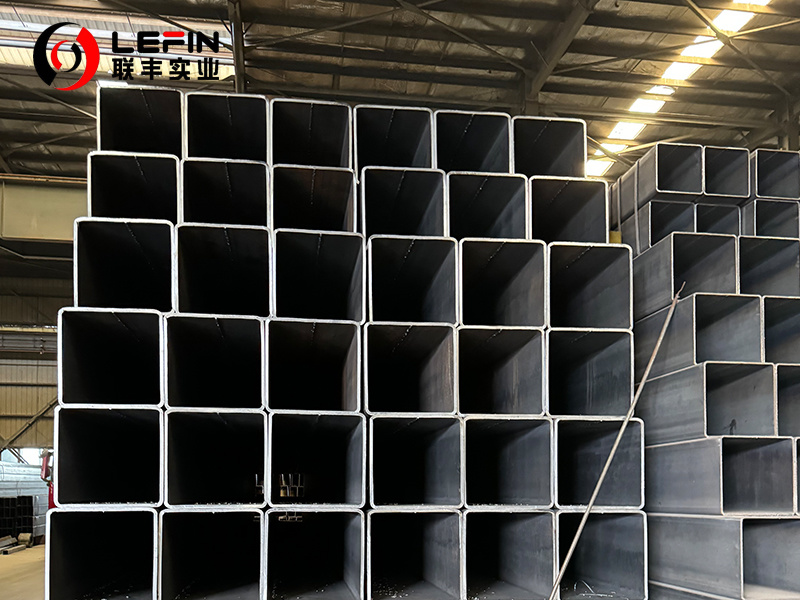

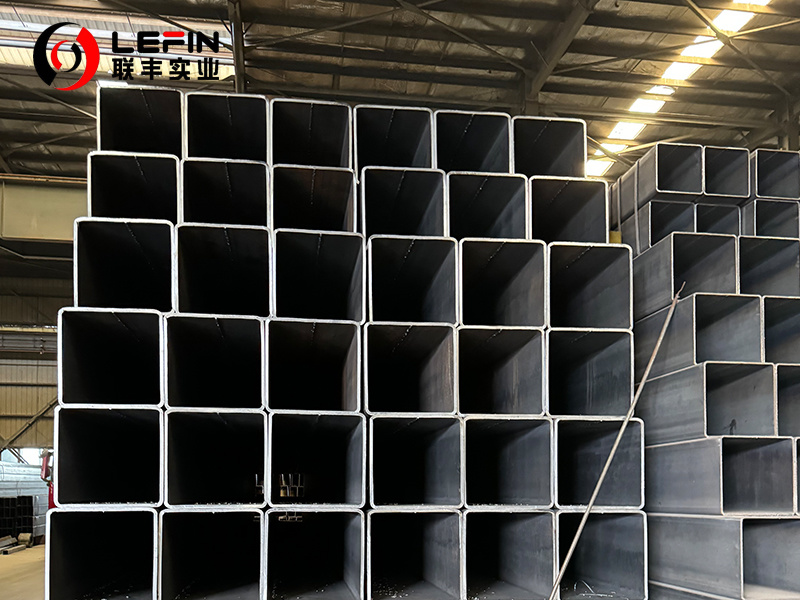

EN 10219 is the European standard for cold-formed welded structural hollow profiles, applicable to non-alloy and fine-grained steels. This type of steel pipe is widely used in fields such as construction, mechanical manufacturing, and infrastructure building.

To help you quickly understand the differences among various steel grades in the EN 10219 standard, I summarize the key information in a table:

EN 10219 comparison of major steel grades

Steel grade Minimum yield strength (MPa) Impact toughness requirements Main Features Applicable scenarios S235JRH

≥ 235 Room temperature Has good weldability and formability , with no specific impact toughness requirements General structural components and mechanical parts S275J0H ≥ 275 0°C Has a higher strength than S235JRH and is suitable for structures that bear higher loads Static load environments such as building structures and mechanical frames. S275J2H ≥ 275 -20°C The strength is the same as that of S275J0H, but it is more suitable for low-temperature environments. J2 indicates that it guarantees impact performance at -20°C Structural components in low-temperature environments. S355J0H ≥ 355 0°C High-strength steel, used for structures bearing heavy loads Structures in large-scale buildings and engineering projects that bear relatively high static loads. S355J2H ≥ 355 -20°C Has the same strength as S355J0H, but it is used in lower-temperature environments. J2 indicates that it guarantees impact performance at -20°C. Bridges, heavy machinery and other situations that may be subjected to certain dynamic loads or low-temperature environments. S355K2H ≥ 355 -20°C Strength is the same as S355J0H/J2H, but it offers higher impact toughness and better minimum impact energy.K2 indicates superior impact performance at -20°C. Heavy structures, offshore platforms or high dynamic load environments with higher requirements for impact toughness. S355NH ≥ 355

(thickness≤16mm)

-50°C Fine-grained steel, usually normalized or hot-rolled, features excellent weldability and outstanding toughness, suitable for low-temperature and high-impact environments. Bridge engineering, offshore platforms, heavy machinery, power facilities (such as transmission towers), etc. Interpret steel grade

There are specific rules for naming steel grades in EN 10219:

- The letter "S" stands for Structural Steel.

- Subsequent numbers (such as 235, 275, 355) : indicate the minimum yield strength (unit: MPa) when the thickness is ≤16mm.

- Impact toughness code:

JR: Room temperature impact performance.

J0: Impact performance at 0°C.

J2 or K2: Impact performance at -20°C (K2 usually indicates a higher impact energy than J2).

L: -50°C impact performance (commonly seen in fine-grained steels, such as S355NLH).

- The letter "H" stands for Hollow sections.

How to choose the right grade of steel?

When choosing steel grades, the following points should be mainly considered:

1.Strength requirements:

Select based on the load requirements of the structural design (such as 235MPa, 275MPa, 355MPa).

2. Ambient temperature and toughness:If the structure is in a low-temperature environment or may be subjected to impact loads, steel grades with good low-temperature impact toughness (such as J2, K2 or NL/L) should be selected.

3. Cost consideration:Under the premise of meeting performance requirements, choose steel grades with higher cost performance. For instance, when there are no special requirements for low temperatures, S235JRH may be more economical than S355J2H.

4. Processing and Welding:Almost all EN 10219 steel grades have good weldability. However, for steels with higher strength or higher carbon equivalent (CEV), more attention should be paid during welding to prevent cold cracking.

5. Corrosive environment:If it is used in a damp or corrosive environment, EN 10219 steel pipes with surface treatments such as hot-dip galvanizing can be considered.

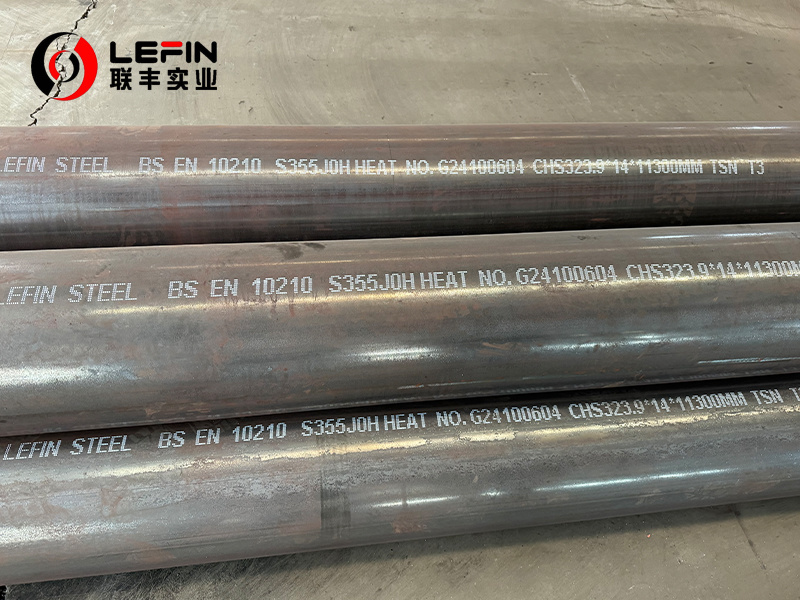

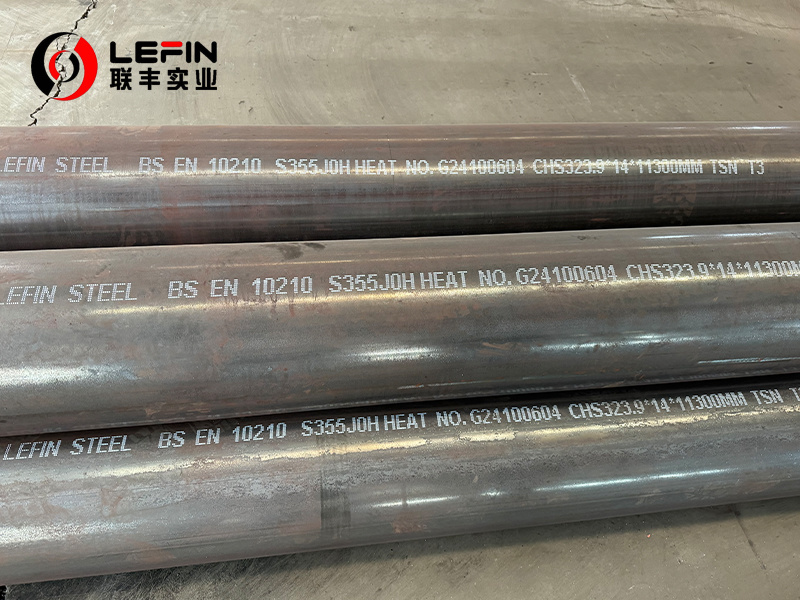

The difference between EN 10219 and EN 10210

You may also encounter the EN 10210 standard, which is also the European standard for structural hollow profiles, but there are key differences between the two:

Characteristics EN 10219 (Cold Forming) EN 10210 (Hot Forming) Manufacturing Technique Cold bending forming, welding at room temperature Hot rolling or hot drawing forming Inner Stress The residual stress is relatively high The residual stress is relatively low Dimensional Accuracy It is usually higher and has a smoother surface Slightly wider tolerance Impact Toughness Relatively low It is usually better because the thermal working process improves the microstructure Typical applications Static or low-impact load fields such as building structures (frames, pillars), mechanical manufacturing, guardrails, and supports Fields such as Bridges, offshore platforms, heavy machinery, and cranes that are subject to high dynamic loads or impacts Summary

When choosing EN 10219 steel pipes, the key is to match your project requirements: strength, ambient temperature (especially impact toughness), budget, and whether special treatments (such as galvanizing) are needed.

Steel Pipe EN 10219

Subcategory

Keyword

- Details

-

EN 10219 is the European standard for cold-formed welded structural hollow profiles, applicable to non-alloy and fine-grained steels. This type of steel pipe is widely used in fields such as construction, mechanical manufacturing, and infrastructure building.

To help you quickly understand the differences among various steel grades in the EN 10219 standard, I summarize the key information in a table:

EN 10219 comparison of major steel grades

Steel grade Minimum yield strength (MPa) Impact toughness requirements Main Features Applicable scenarios S235JRH

≥ 235 Room temperature Has good weldability and formability , with no specific impact toughness requirements General structural components and mechanical parts S275J0H ≥ 275 0°C Has a higher strength than S235JRH and is suitable for structures that bear higher loads Static load environments such as building structures and mechanical frames. S275J2H ≥ 275 -20°C The strength is the same as that of S275J0H, but it is more suitable for low-temperature environments. J2 indicates that it guarantees impact performance at -20°C Structural components in low-temperature environments. S355J0H ≥ 355 0°C High-strength steel, used for structures bearing heavy loads Structures in large-scale buildings and engineering projects that bear relatively high static loads. S355J2H ≥ 355 -20°C Has the same strength as S355J0H, but it is used in lower-temperature environments. J2 indicates that it guarantees impact performance at -20°C. Bridges, heavy machinery and other situations that may be subjected to certain dynamic loads or low-temperature environments. S355K2H ≥ 355 -20°C Strength is the same as S355J0H/J2H, but it offers higher impact toughness and better minimum impact energy.K2 indicates superior impact performance at -20°C. Heavy structures, offshore platforms or high dynamic load environments with higher requirements for impact toughness. S355NH ≥ 355

(thickness≤16mm)

-50°C Fine-grained steel, usually normalized or hot-rolled, features excellent weldability and outstanding toughness, suitable for low-temperature and high-impact environments. Bridge engineering, offshore platforms, heavy machinery, power facilities (such as transmission towers), etc. Interpret steel grade

There are specific rules for naming steel grades in EN 10219:

- The letter "S" stands for Structural Steel.

- Subsequent numbers (such as 235, 275, 355) : indicate the minimum yield strength (unit: MPa) when the thickness is ≤16mm.

- Impact toughness code:

JR: Room temperature impact performance.

J0: Impact performance at 0°C.

J2 or K2: Impact performance at -20°C (K2 usually indicates a higher impact energy than J2).

L: -50°C impact performance (commonly seen in fine-grained steels, such as S355NLH).

- The letter "H" stands for Hollow sections.

How to choose the right grade of steel?

When choosing steel grades, the following points should be mainly considered:

1.Strength requirements:

Select based on the load requirements of the structural design (such as 235MPa, 275MPa, 355MPa).

2. Ambient temperature and toughness:If the structure is in a low-temperature environment or may be subjected to impact loads, steel grades with good low-temperature impact toughness (such as J2, K2 or NL/L) should be selected.

3. Cost consideration:Under the premise of meeting performance requirements, choose steel grades with higher cost performance. For instance, when there are no special requirements for low temperatures, S235JRH may be more economical than S355J2H.

4. Processing and Welding:Almost all EN 10219 steel grades have good weldability. However, for steels with higher strength or higher carbon equivalent (CEV), more attention should be paid during welding to prevent cold cracking.

5. Corrosive environment:If it is used in a damp or corrosive environment, EN 10219 steel pipes with surface treatments such as hot-dip galvanizing can be considered.

The difference between EN 10219 and EN 10210

You may also encounter the EN 10210 standard, which is also the European standard for structural hollow profiles, but there are key differences between the two:

Characteristics EN 10219 (Cold Forming) EN 10210 (Hot Forming) Manufacturing Technique Cold bending forming, welding at room temperature Hot rolling or hot drawing forming Inner Stress The residual stress is relatively high The residual stress is relatively low Dimensional Accuracy It is usually higher and has a smoother surface Slightly wider tolerance Impact Toughness Relatively low It is usually better because the thermal working process improves the microstructure Typical applications Static or low-impact load fields such as building structures (frames, pillars), mechanical manufacturing, guardrails, and supports Fields such as Bridges, offshore platforms, heavy machinery, and cranes that are subject to high dynamic loads or impacts Summary

When choosing EN 10219 steel pipes, the key is to match your project requirements: strength, ambient temperature (especially impact toughness), budget, and whether special treatments (such as galvanizing) are needed.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn