- Details

-

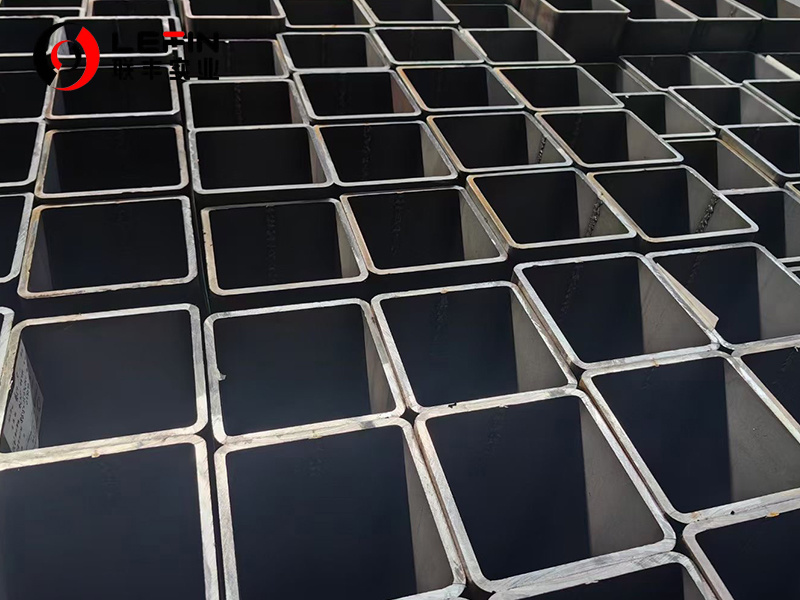

EN10210 is a European standard, whose full name is "Hot finished structural hollow sections of non-alloy and fine grain steels", that is, "hot working structural hollow sections of non-alloy and fine grain steel". This standard specifies in detail its chemical composition, mechanical properties, dimensional tolerances and testing methods.

The unique features of EN10210 seamless pipe:

The core feature of EN10210 seamless pipe lies in its "hot forming" process and strict standard requirements, which distinguishes it from ordinary welded pipes and other standard seamless pipes.

1. Excellent mechanical properties and uniformity

◦ Hot forming process:EN10210 seamless tubes are produced through hot extrusion or hot piercing. The steel billet is heated above the recrystallization temperature and then formed. This process eliminates the internal stress of the material and refines the grain structure, thereby making the mechanical properties of the pipe (such as tensile strength, yield strength, and impact toughness) very uniform and stable throughout the entire cross-section.

◦ Comparison with welded pipes:

The weld seam of welded pipes (such as EN10219 cold-formed pipes) is a relatively weak area, and its performance differs from that of the base material. Seamless pipes have no weld seams, so they have consistent performance and higher reliability.

2. Precise chemical composition and performance guarantee:

This standard imposes strict restrictions on the chemical composition of steel, such as the content of carbon, manganese, sulfur and phosphorus, ensuring good weldability, formability and toughness.The standard clearly stipulates the minimum yield strength, tensile strength and impact energy that different steel grades (such as S235JRH, S275J0H, S355J2H, S355K2H, etc.) must achieve (especially the Charpy V-notch impact test at 0°C or -20°C). This traceable and guaranteed performance is the basis for its application in critical structures.

3. Excellent dimensional accuracy and surface quality:

The standard has strict tolerance requirements for the outer diameter, wall thickness, ellipticity and straightness of pipes.As it is thermoformed, the inner surface of the pipe has no weld scars or burrs, and the outer surface has been treated (such as shot blasting for rust removal), with high quality, which is convenient for subsequent spraying and anti-corrosion treatment.

4. Good processability:

Due to its uniform metallographic structure and stable performance, EN10210 seamless tubes are highly suitable for subsequent processing such as bending, flanging, cutting and welding, and are less prone to cracking or performance degradation.In short, the uniqueness of EN10210 seamless pipe lies in the fact that it offers a high-performance, highly reliable, weld-free and isotropic structural material through thermoforming processes and strict quality control in accordance with European standards.

Common application fields

It is precisely because of the above outstanding characteristics that EN10210 seamless pipes are widely used in fields with extremely high requirements for safety, reliability and load-bearing capacity:

1. Architecture and Structural Engineering (the main field) :

The roofs and main supporting structures of large public buildings: airport terminals, sports venues, exhibition centers, and shopping centers. These Spaces require large-span trusses and grid structures, and seamless pipes are the ideal choice for manufacturing these key load-bearing components.High-rise buildings: Used as main load-bearing structural components such as columns and beams.

Bridge construction: It is used for the piers and deck support structures of pedestrian overpasses and highway Bridges.

2. Machinery and Heavy Equipment Manufacturing:

- Construction machinery: booms, support legs and chassis frames of excavators, cranes and concrete pump trucks. These parts are subjected to tremendous alternating stress and impact loads, which impose extremely high requirements on the fatigue strength and toughness of the material.

- Agricultural machinery: Chassis and load-bearing components of heavy-duty tractors and harvesters.

- Hydraulic cylinder barrel: High-quality seamless tubes are the core material for manufacturing hydraulic cylinder bodies.

3. Energy and transportation sector:

- Wind power generation: It is used to manufacture the supporting structural components and platforms inside the wind turbine tower.

- Offshore platform: A modular structure for oil drilling platforms.

- Roll-on/roll-off ships and trucks: used for manufacturing frames and load-bearing skeletons.

4. Other high-end applications:

- Stage lighting stand: In situations where high intensity and aesthetic appeal are required.

- High-end furniture and decoration: By taking advantage of its elegant arc transitions and structural sense, products that combine functionality and aesthetics are designed.

Summary

Characteristics

EN10210 hot-formed seamless pipe

Common welded pipe (such as EN10219)

Manufacturing Technique

Hot extrusion/piercing without weld seams

Cold bending followed by high-frequency welding with weld seams

Uniformity Of Performance

Excellent, and the performance of the entire cross-section is consistent

There are performance differences between the weld area and the base material

Loading Capacity

It has a high pressure-bearing capacity and good fatigue resistance, but relatively low performance.

The weld seam is a potential weak point

Size Range

The wall thickness is usually relatively thick, and the size specifications are relatively few.

The wall thickness is relatively thin, and the size specifications are very flexible

Cost

Relatively high

Relatively low

Chief Application

Key load-bearing structures, heavy machinery

General structures for high-pressure applications, supports, and low-stress environments

Therefore, when your project has extremely high requirements for structural integrity, safety and dynamic load capacity, EN10210 seamless pipe is usually the preferred material.

EN 10210 SEAMLESS PIPE

Subcategory

Keyword

- Details

-

EN10210 is a European standard, whose full name is "Hot finished structural hollow sections of non-alloy and fine grain steels", that is, "hot working structural hollow sections of non-alloy and fine grain steel". This standard specifies in detail its chemical composition, mechanical properties, dimensional tolerances and testing methods.

The unique features of EN10210 seamless pipe:

The core feature of EN10210 seamless pipe lies in its "hot forming" process and strict standard requirements, which distinguishes it from ordinary welded pipes and other standard seamless pipes.

1. Excellent mechanical properties and uniformity

◦ Hot forming process:EN10210 seamless tubes are produced through hot extrusion or hot piercing. The steel billet is heated above the recrystallization temperature and then formed. This process eliminates the internal stress of the material and refines the grain structure, thereby making the mechanical properties of the pipe (such as tensile strength, yield strength, and impact toughness) very uniform and stable throughout the entire cross-section.

◦ Comparison with welded pipes:

The weld seam of welded pipes (such as EN10219 cold-formed pipes) is a relatively weak area, and its performance differs from that of the base material. Seamless pipes have no weld seams, so they have consistent performance and higher reliability.

2. Precise chemical composition and performance guarantee:

This standard imposes strict restrictions on the chemical composition of steel, such as the content of carbon, manganese, sulfur and phosphorus, ensuring good weldability, formability and toughness.The standard clearly stipulates the minimum yield strength, tensile strength and impact energy that different steel grades (such as S235JRH, S275J0H, S355J2H, S355K2H, etc.) must achieve (especially the Charpy V-notch impact test at 0°C or -20°C). This traceable and guaranteed performance is the basis for its application in critical structures.

3. Excellent dimensional accuracy and surface quality:

The standard has strict tolerance requirements for the outer diameter, wall thickness, ellipticity and straightness of pipes.As it is thermoformed, the inner surface of the pipe has no weld scars or burrs, and the outer surface has been treated (such as shot blasting for rust removal), with high quality, which is convenient for subsequent spraying and anti-corrosion treatment.

4. Good processability:

Due to its uniform metallographic structure and stable performance, EN10210 seamless tubes are highly suitable for subsequent processing such as bending, flanging, cutting and welding, and are less prone to cracking or performance degradation.In short, the uniqueness of EN10210 seamless pipe lies in the fact that it offers a high-performance, highly reliable, weld-free and isotropic structural material through thermoforming processes and strict quality control in accordance with European standards.

Common application fields

It is precisely because of the above outstanding characteristics that EN10210 seamless pipes are widely used in fields with extremely high requirements for safety, reliability and load-bearing capacity:

1. Architecture and Structural Engineering (the main field) :

The roofs and main supporting structures of large public buildings: airport terminals, sports venues, exhibition centers, and shopping centers. These Spaces require large-span trusses and grid structures, and seamless pipes are the ideal choice for manufacturing these key load-bearing components.High-rise buildings: Used as main load-bearing structural components such as columns and beams.

Bridge construction: It is used for the piers and deck support structures of pedestrian overpasses and highway Bridges.

2. Machinery and Heavy Equipment Manufacturing:

- Construction machinery: booms, support legs and chassis frames of excavators, cranes and concrete pump trucks. These parts are subjected to tremendous alternating stress and impact loads, which impose extremely high requirements on the fatigue strength and toughness of the material.

- Agricultural machinery: Chassis and load-bearing components of heavy-duty tractors and harvesters.

- Hydraulic cylinder barrel: High-quality seamless tubes are the core material for manufacturing hydraulic cylinder bodies.

3. Energy and transportation sector:

- Wind power generation: It is used to manufacture the supporting structural components and platforms inside the wind turbine tower.

- Offshore platform: A modular structure for oil drilling platforms.

- Roll-on/roll-off ships and trucks: used for manufacturing frames and load-bearing skeletons.

4. Other high-end applications:

- Stage lighting stand: In situations where high intensity and aesthetic appeal are required.

- High-end furniture and decoration: By taking advantage of its elegant arc transitions and structural sense, products that combine functionality and aesthetics are designed.

Summary

Characteristics

EN10210 hot-formed seamless pipe

Common welded pipe (such as EN10219)

Manufacturing Technique

Hot extrusion/piercing without weld seams

Cold bending followed by high-frequency welding with weld seams

Uniformity Of Performance

Excellent, and the performance of the entire cross-section is consistent

There are performance differences between the weld area and the base material

Loading Capacity

It has a high pressure-bearing capacity and good fatigue resistance, but relatively low performance.

The weld seam is a potential weak point

Size Range

The wall thickness is usually relatively thick, and the size specifications are relatively few.

The wall thickness is relatively thin, and the size specifications are very flexible

Cost

Relatively high

Relatively low

Chief Application

Key load-bearing structures, heavy machinery

General structures for high-pressure applications, supports, and low-stress environments

Therefore, when your project has extremely high requirements for structural integrity, safety and dynamic load capacity, EN10210 seamless pipe is usually the preferred material.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn