- Details

-

Introduction

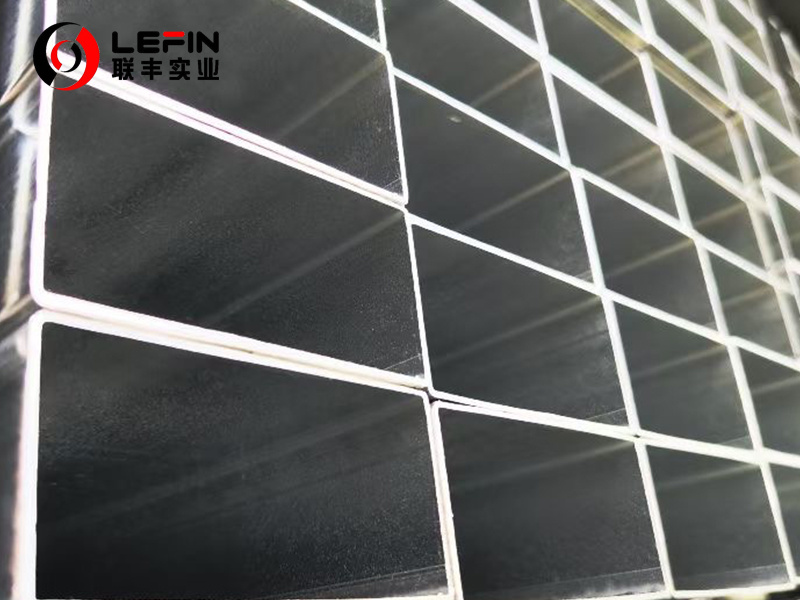

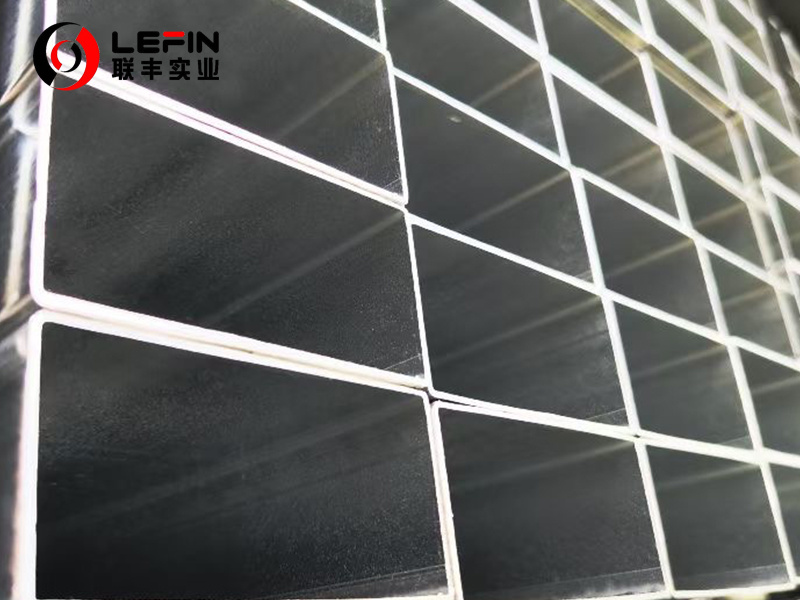

ASTM A1085 is a standard specification for Cold-Formed, Welded, High-Strength, Low-Alloy Structural Tubing in round, square, and rectangular shapes, intended for use in structural applications. Introduced in 2013, it represents a significant advancement over older standards like A500 by offering enhanced performance, greater predictability in design strength, and improved durability.This standard was developed through a collaboration between the American Institute of Steel Construction (AISC), the Steel Tube Institute (STI), and ASTM International to provide a product that allows for more efficient and economical structural design.

Key Characteristics- Higher Strength-to-Weight Ratio:

A1085 specifies a minimum yield strength (Fy) of 50 ksi (345 MPa) and a minimum tensile strength (Fu) of 62 ksi (427 MPa). This is higher than the typical grades in A500 (Grade B: Fy = 46 ksi, Grade C: Fy = 50 ksi) and allows engineers to use less material to achieve the same load-bearing capacity, leading to lighter and often more cost-effective structures.

- Enhanced Ductility and Toughness:

It requires a minimum elongation of 18%, which is higher than the requirements for A500. This ensures the steel is more ductile, meaning it can undergo significant deformation before fracture-a critical property for absorbing energy in seismic events or preventing brittle failure.

- Stricter Chemical Composition (Chemistry):

A1085 has tighter controls on the chemical elements like carbon, phosphorus, and sulfur. It also includes maximum limits for Carbon Equivalent (CE) to ensure excellent weldability and to minimize the risk of cracking in the heat-affected zone during fabrication.

- Superior Dimensional Tolerances:

The tolerances for cross-sectional dimensions (e.g., outside dimensions, wall thickness) and straightness are tighter and more stringent than those for A500. This results in members that are more uniform and predictable, which simplifies fabrication and fit-up, especially in complex connections.

- Direct Use of Specified Minimum Yield Strength:

This is a major advantage for structural designers. The AISC Steel Construction Manual allows designers to use the full specified minimum yield strength (50 ksi) in their calculations without the strength reduction factors required for A500 material. This leads to simpler, more direct, and more efficient design.

Applications

The enhanced properties of ASTM A1085 HSS make it ideal for demanding structural applications where performance, efficiency, and reliability are paramount:- Seismic-Resistant Framing: Its high ductility and toughness make it an excellent choice for moment frames and braced frames in earthquake-prone areas.

- Long-Span Trusses and Arches: The high strength-to-weight ratio allows for longer spans with less self-weight.

- High-Rise Buildings: Used as columns and braces, where saving weight on upper floors can have a significant cascading effect on the entire structure's design.

- Heavily Loaded Columns: The combination of high strength and good ductility provides an efficient solution for supporting large loads.

- Bridge Components: Used in various bridge elements where durability and high performance are required.

- Architecturally Exposed Structural Steel (AESS): The tight dimensional tolerances result in cleaner lines and better fit, making it suitable for structures where the steel is intentionally left exposed for aesthetic reasons.

Comparison With Other Common ASTM Standards

Feature ASTM A1085 ASTM A500 Grade C ASTM A500 Grade B ASTM A501 (Hot-Formed) Yield Strength (Fy) 50 ksi (345 MPa) 50 ksi (345 MPa) 46 ksi (317 MPa) 36 ksi (250 MPa) Tensile Strength (Fu) 62 ksi (427 MPa) 62 ksi (427 MPa) 58 ksi (400 MPa) 58 ksi (400 MPa) Min. Elongation 18% 14% 14% 14% Chemistry Control Stringent; Max CE for weldability Less Stringent Less Stringent Less Stringent Dimensional Tolerances Tightest Standard (Commercial) Standard (Commercial) Standard (Commercial) Primary Manufacturing Cold-Formed & Welded Cold-Formed & Welded Cold-Formed & Welded Hot-Formed & Welded Key Advantage High performance, ductility, design efficiency. Full Fy can be used. General purpose, widely available. Most common, cost-effective for many uses. Good for heavy sections, but largely superseded. AISC Design Strength Can use Fy = 50 ksi directly Must use Fy = 0.9 * 50 = 45 ksi (for rectangular HSS) Must use Fy = 0.9 * 46 = 41.4 ksi (for rectangular HSS) Can use Fy = 36 ksi directly Summary

- vs. A500: While A500 Grade C has the same published minimum yield strength (50 ksi), A1085 is a superior product in almost every way. It guarantees better ductility, tighter chemistry control for welding, and stricter dimensional tolerances. Crucially, for design, A1085 allows the use of the full 50 ksi yield strength, whereas A500 requires a reduction, making A1085 materially more efficient.

- vs. A501: A501 is an older standard for hot-formed tubing. It has a much lower yield strength (36 ksi) and generally poorer dimensional properties. A1085 (and A500) have largely replaced A501 for most structural applications due to their superior and more consistent properties.

In conclusion, ASTM A1085 is a premium, high-performance HSS designed for modern, efficient, and resilient structural design. It offers tangible benefits over A500 and A501, particularly in applications where its enhanced properties can be fully utilized to create safer, lighter, and more economical structures.

ASTM A1085 Hollow Structural Sections (HHS)

Subcategory

Keyword

- Details

-

Introduction

ASTM A1085 is a standard specification for Cold-Formed, Welded, High-Strength, Low-Alloy Structural Tubing in round, square, and rectangular shapes, intended for use in structural applications. Introduced in 2013, it represents a significant advancement over older standards like A500 by offering enhanced performance, greater predictability in design strength, and improved durability.This standard was developed through a collaboration between the American Institute of Steel Construction (AISC), the Steel Tube Institute (STI), and ASTM International to provide a product that allows for more efficient and economical structural design.

Key Characteristics- Higher Strength-to-Weight Ratio:

A1085 specifies a minimum yield strength (Fy) of 50 ksi (345 MPa) and a minimum tensile strength (Fu) of 62 ksi (427 MPa). This is higher than the typical grades in A500 (Grade B: Fy = 46 ksi, Grade C: Fy = 50 ksi) and allows engineers to use less material to achieve the same load-bearing capacity, leading to lighter and often more cost-effective structures.

- Enhanced Ductility and Toughness:

It requires a minimum elongation of 18%, which is higher than the requirements for A500. This ensures the steel is more ductile, meaning it can undergo significant deformation before fracture-a critical property for absorbing energy in seismic events or preventing brittle failure.

- Stricter Chemical Composition (Chemistry):

A1085 has tighter controls on the chemical elements like carbon, phosphorus, and sulfur. It also includes maximum limits for Carbon Equivalent (CE) to ensure excellent weldability and to minimize the risk of cracking in the heat-affected zone during fabrication.

- Superior Dimensional Tolerances:

The tolerances for cross-sectional dimensions (e.g., outside dimensions, wall thickness) and straightness are tighter and more stringent than those for A500. This results in members that are more uniform and predictable, which simplifies fabrication and fit-up, especially in complex connections.

- Direct Use of Specified Minimum Yield Strength:

This is a major advantage for structural designers. The AISC Steel Construction Manual allows designers to use the full specified minimum yield strength (50 ksi) in their calculations without the strength reduction factors required for A500 material. This leads to simpler, more direct, and more efficient design.

Applications

The enhanced properties of ASTM A1085 HSS make it ideal for demanding structural applications where performance, efficiency, and reliability are paramount:- Seismic-Resistant Framing: Its high ductility and toughness make it an excellent choice for moment frames and braced frames in earthquake-prone areas.

- Long-Span Trusses and Arches: The high strength-to-weight ratio allows for longer spans with less self-weight.

- High-Rise Buildings: Used as columns and braces, where saving weight on upper floors can have a significant cascading effect on the entire structure's design.

- Heavily Loaded Columns: The combination of high strength and good ductility provides an efficient solution for supporting large loads.

- Bridge Components: Used in various bridge elements where durability and high performance are required.

- Architecturally Exposed Structural Steel (AESS): The tight dimensional tolerances result in cleaner lines and better fit, making it suitable for structures where the steel is intentionally left exposed for aesthetic reasons.

Comparison With Other Common ASTM Standards

Feature ASTM A1085 ASTM A500 Grade C ASTM A500 Grade B ASTM A501 (Hot-Formed) Yield Strength (Fy) 50 ksi (345 MPa) 50 ksi (345 MPa) 46 ksi (317 MPa) 36 ksi (250 MPa) Tensile Strength (Fu) 62 ksi (427 MPa) 62 ksi (427 MPa) 58 ksi (400 MPa) 58 ksi (400 MPa) Min. Elongation 18% 14% 14% 14% Chemistry Control Stringent; Max CE for weldability Less Stringent Less Stringent Less Stringent Dimensional Tolerances Tightest Standard (Commercial) Standard (Commercial) Standard (Commercial) Primary Manufacturing Cold-Formed & Welded Cold-Formed & Welded Cold-Formed & Welded Hot-Formed & Welded Key Advantage High performance, ductility, design efficiency. Full Fy can be used. General purpose, widely available. Most common, cost-effective for many uses. Good for heavy sections, but largely superseded. AISC Design Strength Can use Fy = 50 ksi directly Must use Fy = 0.9 * 50 = 45 ksi (for rectangular HSS) Must use Fy = 0.9 * 46 = 41.4 ksi (for rectangular HSS) Can use Fy = 36 ksi directly Summary

- vs. A500: While A500 Grade C has the same published minimum yield strength (50 ksi), A1085 is a superior product in almost every way. It guarantees better ductility, tighter chemistry control for welding, and stricter dimensional tolerances. Crucially, for design, A1085 allows the use of the full 50 ksi yield strength, whereas A500 requires a reduction, making A1085 materially more efficient.

- vs. A501: A501 is an older standard for hot-formed tubing. It has a much lower yield strength (36 ksi) and generally poorer dimensional properties. A1085 (and A500) have largely replaced A501 for most structural applications due to their superior and more consistent properties.

In conclusion, ASTM A1085 is a premium, high-performance HSS designed for modern, efficient, and resilient structural design. It offers tangible benefits over A500 and A501, particularly in applications where its enhanced properties can be fully utilized to create safer, lighter, and more economical structures.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn