- Details

-

ASTM A501 seamless steel pipe is a kind of carbon steel structure seamless steel pipe that complies with the standards of the American Society for Testing and Materials (ASTM), and is mainly used in fields such as Bridges, buildings, and mechanical manufacturing. The following is a detailed description from four aspects: characteristics, uses, standard requirements, and differences from ASTM A500:

I. Characteristics

High strength and uniformity

Seamless tubes are manufactured through thermoforming processes, featuring no weld defects and uniform material strength distribution. They are suitable for structural scenarios that require high pressure or high stress. For instance, the minimum yield strength of its B-grade material can reach 345 MPa, which is significantly higher than that of ordinary carbon steel.

Good processing performance

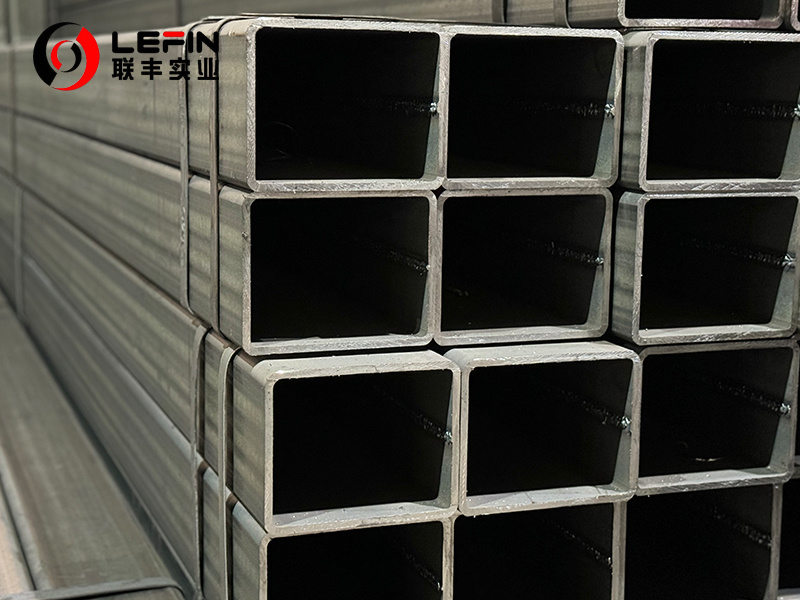

The thermoforming process endows it with excellent plasticity, allowing it to be processed into square, rectangular or irregular-shaped structural tubes through bending, welding and other methods, meeting diverse engineering requirements.

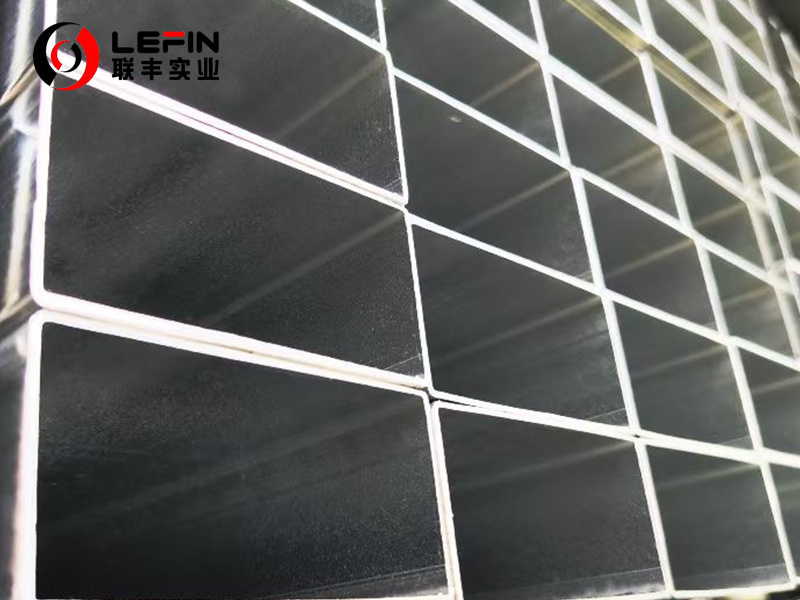

Flexible surface treatment

Steel pipes can be provided with black (ungalvanized) or hot-dip galvanized surfaces. The latter can effectively resist corrosion, extend service life, and is suitable for outdoor or humid environments.

Wide range of sizes

The outer diameter of the circular pipe covers NPS 1/2 to NPS 24 (approximately 15-600 mm), and the wall thickness ranges from 0.109 to 1.000 inches (2.77-25.4 mm), which can meet the structural design requirements of different specifications.

II. Uses

Architecture and Bridges

It is used for constructing frames, supporting structures, bridge trusses, etc., such as columns and beams in buildings, as well as load-bearing components of Bridges.

Mechanical manufacturing

As raw materials for mechanical parts, such as crane booms, structural components of railway vehicles, and connecting parts in air conditioning equipment (such as oil separators).

General structural engineering

It is suitable for scenarios that require reliable structural support, such as industrial equipment brackets, warehouse shelves, etc.III. Standard Requirements

(1) Material grade and mechanical properties

- Grade A: Minimum yield strength 250 MPa, suitable for general structural loads.

- Grade B: Minimum yield strength 345 MPa, suitable for high-stress environments.

- Tensile strength and elongation: The standard does not explicitly provide specific values, but it usually requires the material to have good ductility to ensure structural safety (please refer to the latest standard document).

(2) Chemical Composition

The main component is carbon steel. The specific element contents need to comply with the ASTM A501 standard (such as carbon, manganese, phosphorus, sulfur, etc.), but the search results do not provide detailed values. It is necessary to refer to the original standard.

(3) Manufacturing process

Hot forming: Formed through hot rolling or forging processes to ensure the material's density and strength.

Seamless manufacturing: No weld seams, avoiding welding defects and enhancing overall performance.

(4) Inspection and Testing

Tensile test: Verify the yield strength and tensile strength of the material.

Flattening test: Applicable to circular tubes, to examine their resistance to deformation.

Dimensional tolerance: Outer diameter, wall thickness, Angle, etc. must comply with the standard provisions. For example, the outer diameter tolerance of circular pipes is ±1% (for large sizes) or ±0.020 inches (for small sizes).

(5) Surface quality

The inner and outer surfaces of the steel pipe should be smooth, free of cracks, scars and other defects, and the galvanized coating should be evenly attached.

IV. Differences from ASTM A500

Comparison items ASTM A501 ASTM A500 Manufacturing process Hot forming (hot rolling or forging), seamless or welded Cold forming (cold rolling or cold bending), seamless or welded Material grades Grade A (250 MPa), Grade B (345 MPa). Grade A (269 MPa), Grade B (315 MPa), Grade C (345 MPa), Grade D (415 MPa). Mechanical properties Grade B yield strength 345 MPa, tensile strength not specified (usually higher than 400 MPa). Grade B yield strength: 315 MPa, tensile strength: 400 MPa. Grade D requires heat treatment to enhance performance. Application scenarios Buildings, Bridges, and high-stress mechanical structures. Mechanical parts, automotive structures, cold-formed components (such as guardrails, signs). Size range The maximum outer diameter of the circular tube is NPS 24 (600 mm), and the wall thickness is 0.109-1.000 inches. The maximum circumference is 88 inches (2,235 mm), and the wall thickness is no more than 1 inch (25.4 mm). Surface treatment The surface treatment is black or hot-dip galvanized. It is usually black and can be galvanized as an option. Typical applications Large structures that require high strength and weather resistance. Small and medium-sized structural components that require cold forming processing.

STEEL PIPE ASTM A501 SEAMLESS

Subcategory

Keyword

- Details

-

ASTM A501 seamless steel pipe is a kind of carbon steel structure seamless steel pipe that complies with the standards of the American Society for Testing and Materials (ASTM), and is mainly used in fields such as Bridges, buildings, and mechanical manufacturing. The following is a detailed description from four aspects: characteristics, uses, standard requirements, and differences from ASTM A500:

I. Characteristics

High strength and uniformity

Seamless tubes are manufactured through thermoforming processes, featuring no weld defects and uniform material strength distribution. They are suitable for structural scenarios that require high pressure or high stress. For instance, the minimum yield strength of its B-grade material can reach 345 MPa, which is significantly higher than that of ordinary carbon steel.

Good processing performance

The thermoforming process endows it with excellent plasticity, allowing it to be processed into square, rectangular or irregular-shaped structural tubes through bending, welding and other methods, meeting diverse engineering requirements.

Flexible surface treatment

Steel pipes can be provided with black (ungalvanized) or hot-dip galvanized surfaces. The latter can effectively resist corrosion, extend service life, and is suitable for outdoor or humid environments.

Wide range of sizes

The outer diameter of the circular pipe covers NPS 1/2 to NPS 24 (approximately 15-600 mm), and the wall thickness ranges from 0.109 to 1.000 inches (2.77-25.4 mm), which can meet the structural design requirements of different specifications.

II. Uses

Architecture and Bridges

It is used for constructing frames, supporting structures, bridge trusses, etc., such as columns and beams in buildings, as well as load-bearing components of Bridges.

Mechanical manufacturing

As raw materials for mechanical parts, such as crane booms, structural components of railway vehicles, and connecting parts in air conditioning equipment (such as oil separators).

General structural engineering

It is suitable for scenarios that require reliable structural support, such as industrial equipment brackets, warehouse shelves, etc.III. Standard Requirements

(1) Material grade and mechanical properties

- Grade A: Minimum yield strength 250 MPa, suitable for general structural loads.

- Grade B: Minimum yield strength 345 MPa, suitable for high-stress environments.

- Tensile strength and elongation: The standard does not explicitly provide specific values, but it usually requires the material to have good ductility to ensure structural safety (please refer to the latest standard document).

(2) Chemical Composition

The main component is carbon steel. The specific element contents need to comply with the ASTM A501 standard (such as carbon, manganese, phosphorus, sulfur, etc.), but the search results do not provide detailed values. It is necessary to refer to the original standard.

(3) Manufacturing process

Hot forming: Formed through hot rolling or forging processes to ensure the material's density and strength.

Seamless manufacturing: No weld seams, avoiding welding defects and enhancing overall performance.

(4) Inspection and Testing

Tensile test: Verify the yield strength and tensile strength of the material.

Flattening test: Applicable to circular tubes, to examine their resistance to deformation.

Dimensional tolerance: Outer diameter, wall thickness, Angle, etc. must comply with the standard provisions. For example, the outer diameter tolerance of circular pipes is ±1% (for large sizes) or ±0.020 inches (for small sizes).

(5) Surface quality

The inner and outer surfaces of the steel pipe should be smooth, free of cracks, scars and other defects, and the galvanized coating should be evenly attached.

IV. Differences from ASTM A500

Comparison items ASTM A501 ASTM A500 Manufacturing process Hot forming (hot rolling or forging), seamless or welded Cold forming (cold rolling or cold bending), seamless or welded Material grades Grade A (250 MPa), Grade B (345 MPa). Grade A (269 MPa), Grade B (315 MPa), Grade C (345 MPa), Grade D (415 MPa). Mechanical properties Grade B yield strength 345 MPa, tensile strength not specified (usually higher than 400 MPa). Grade B yield strength: 315 MPa, tensile strength: 400 MPa. Grade D requires heat treatment to enhance performance. Application scenarios Buildings, Bridges, and high-stress mechanical structures. Mechanical parts, automotive structures, cold-formed components (such as guardrails, signs). Size range The maximum outer diameter of the circular tube is NPS 24 (600 mm), and the wall thickness is 0.109-1.000 inches. The maximum circumference is 88 inches (2,235 mm), and the wall thickness is no more than 1 inch (25.4 mm). Surface treatment The surface treatment is black or hot-dip galvanized. It is usually black and can be galvanized as an option. Typical applications Large structures that require high strength and weather resistance. Small and medium-sized structural components that require cold forming processing.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn