- Details

-

EN 10219 S235JRH is a cold-formed welded structural steel pipe widely used in construction, mechanical manufacturing and infrastructure fields, in compliance with the European standard EN 10219. The following is a detailed analysis of its core features:

1. Material properties and standard requirements

Chemical composition (limits of key elements) :

- Carbon (C) : ≤0.20%

- Manganese (Mn) : 0.60% - 0.90%

- Silicon (Si), phosphorus (P), sulfur (S) : Strictly limit impurity content (P≤0.035%, S≤0.035%).Low-carbon design ensures good weldability and plasticity, and manganese enhances strength.

Mechanical properties:

- Yield strength (Rp0.2) : ≥235 MPa

- Tensile strength (Rm) : 340-480 MPa

- Elongation (A) : ≥23% High elongation indicates excellent plasticity of the material and is suitable for scenarios that require bending or impact.

2. Specifications and dimensional tolerances

Section type and range:

- Round pipe: Outer diameter 88.9-2540mm (wall thickness 2.5-25.4mm)

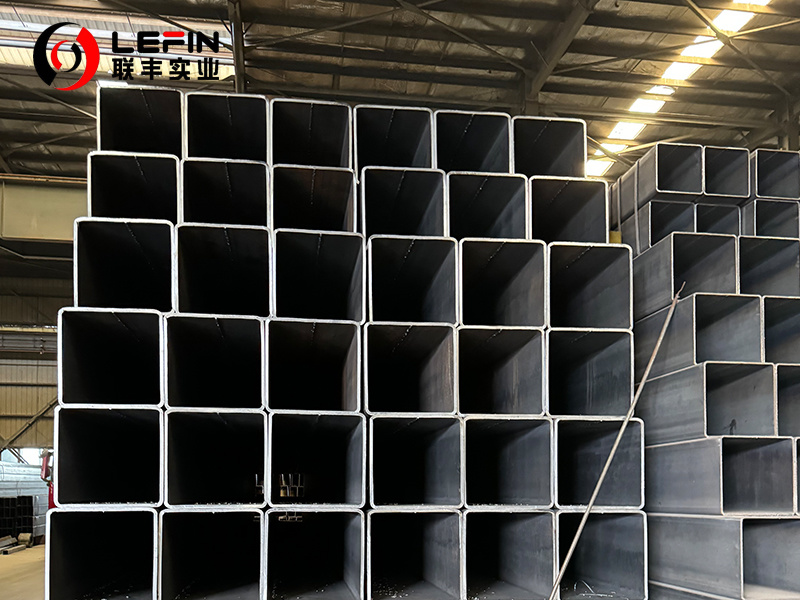

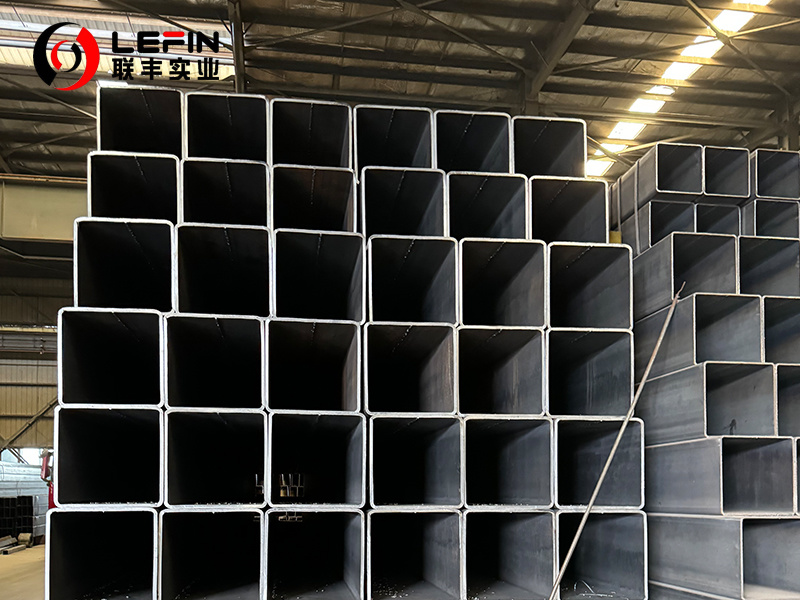

- Square tubes (SHS) : Side length 20-800 mm (wall thickness 2-30 mm)

- Rectangular tubes (RHS) : Long side 20-750mm, short side 20-500mm. Common specifications include 50×50× 3-5mm square tubes, which are used for lightweight structures.

Tolerance requirements:

- Side length tolerance: ± 1.5mm

- Wall thickness tolerance: ±10% the cold forming process ensures high dimensional accuracy and is suitable for precise assembly.

3. Production process and quality control

Manufacturing process:

- Cold bending forming: The steel plate is bent at room temperature and then formed by high-frequency resistance welding (ERW) or submerged arc welding (SAW).

- No heat treatment: No heat treatment is carried out after welding, retaining the cold working hardening effect (strength increases, but residual stress is relatively high).

- Surface treatment: Galvanizing (anti-corrosion) or black annealing (forming an oxide layer to resist corrosion) is available.

Quality inspection:

- Mechanical tests: Tensile and impact tests for each batch (impact toughness at -20℃ must meet the standard).

- Non-destructive testing (NDT) : 100% ultrasonic/radiographic testing of weld seams.

- Water pressure test: Maintain for more than 5 seconds, and the pressure is calculated according to the standard.

4. Application fields

- Building structure: High-rise frame, support columns, roof trusses (high dimensional accuracy facilitates assembly).

- Mechanical manufacturing: Conveying equipment brackets, crane booms (good weldability is required).

- Municipal engineering: Road guardrails, bridge ancillary structures (galvanized anti-corrosion version).

- Other fields: Furniture manufacturing (industrial style design), photovoltaic brackets, billboards.

5. Selection suggestions and certification requirements

Applicable scenario selection:

- Recommended EN 10219 S235JRH: mainly for static loads (such as building supports), cost-sensitive, and requires high precision.

- Unsuitable scenarios: High impact loads (such as crane main beams) or high-temperature environments (>350℃), in which case the thermoforming standard EN 10210 (such as S355J2H) should be selected.

CE certification requirements:

- Compulsory certification: Exports to the EU must comply with the CPR Regulation (EU 305/2011).

- Certified content:

- Initial type inspection (ITT) : Mechanical property and impact toughness tests.

- Factory Production Control (FPC) : Full-process quality system audit.

- Mark usage: After certification, the CE mark can be affixed and a Performance Declaration (DoP) can be issued.

6. Maintenance advice

Maintenance and upkeep

- Regularly check for surface rust. It is recommended to apply anti-corrosion paint (such as inorganic zinc-rich paint) in open-air environments.

- Avoid overloading to prevent plastic deformation.

summary

EN 10219 S235JRH, with its high precision, good weldability and cost-effectiveness, has become the preferred choice for static structural applications. However, it should be noted that its residual stress is relatively high and it is not suitable for dynamic load scenarios. When selecting the type, the engineering requirements should be taken into account. The qualifications and certification documents of the suppliers should be strictly reviewed, and regular maintenance should be carried out to extend the service life.

STEEL PIPE EN 10219 S235JRH

Subcategory

Keyword

- Details

-

EN 10219 S235JRH is a cold-formed welded structural steel pipe widely used in construction, mechanical manufacturing and infrastructure fields, in compliance with the European standard EN 10219. The following is a detailed analysis of its core features:

1. Material properties and standard requirements

Chemical composition (limits of key elements) :

- Carbon (C) : ≤0.20%

- Manganese (Mn) : 0.60% - 0.90%

- Silicon (Si), phosphorus (P), sulfur (S) : Strictly limit impurity content (P≤0.035%, S≤0.035%).Low-carbon design ensures good weldability and plasticity, and manganese enhances strength.

Mechanical properties:

- Yield strength (Rp0.2) : ≥235 MPa

- Tensile strength (Rm) : 340-480 MPa

- Elongation (A) : ≥23% High elongation indicates excellent plasticity of the material and is suitable for scenarios that require bending or impact.

2. Specifications and dimensional tolerances

Section type and range:

- Round pipe: Outer diameter 88.9-2540mm (wall thickness 2.5-25.4mm)

- Square tubes (SHS) : Side length 20-800 mm (wall thickness 2-30 mm)

- Rectangular tubes (RHS) : Long side 20-750mm, short side 20-500mm. Common specifications include 50×50× 3-5mm square tubes, which are used for lightweight structures.

Tolerance requirements:

- Side length tolerance: ± 1.5mm

- Wall thickness tolerance: ±10% the cold forming process ensures high dimensional accuracy and is suitable for precise assembly.

3. Production process and quality control

Manufacturing process:

- Cold bending forming: The steel plate is bent at room temperature and then formed by high-frequency resistance welding (ERW) or submerged arc welding (SAW).

- No heat treatment: No heat treatment is carried out after welding, retaining the cold working hardening effect (strength increases, but residual stress is relatively high).

- Surface treatment: Galvanizing (anti-corrosion) or black annealing (forming an oxide layer to resist corrosion) is available.

Quality inspection:

- Mechanical tests: Tensile and impact tests for each batch (impact toughness at -20℃ must meet the standard).

- Non-destructive testing (NDT) : 100% ultrasonic/radiographic testing of weld seams.

- Water pressure test: Maintain for more than 5 seconds, and the pressure is calculated according to the standard.

4. Application fields

- Building structure: High-rise frame, support columns, roof trusses (high dimensional accuracy facilitates assembly).

- Mechanical manufacturing: Conveying equipment brackets, crane booms (good weldability is required).

- Municipal engineering: Road guardrails, bridge ancillary structures (galvanized anti-corrosion version).

- Other fields: Furniture manufacturing (industrial style design), photovoltaic brackets, billboards.

5. Selection suggestions and certification requirements

Applicable scenario selection:

- Recommended EN 10219 S235JRH: mainly for static loads (such as building supports), cost-sensitive, and requires high precision.

- Unsuitable scenarios: High impact loads (such as crane main beams) or high-temperature environments (>350℃), in which case the thermoforming standard EN 10210 (such as S355J2H) should be selected.

CE certification requirements:

- Compulsory certification: Exports to the EU must comply with the CPR Regulation (EU 305/2011).

- Certified content:

- Initial type inspection (ITT) : Mechanical property and impact toughness tests.

- Factory Production Control (FPC) : Full-process quality system audit.

- Mark usage: After certification, the CE mark can be affixed and a Performance Declaration (DoP) can be issued.

6. Maintenance advice

Maintenance and upkeep

- Regularly check for surface rust. It is recommended to apply anti-corrosion paint (such as inorganic zinc-rich paint) in open-air environments.

- Avoid overloading to prevent plastic deformation.

summary

EN 10219 S235JRH, with its high precision, good weldability and cost-effectiveness, has become the preferred choice for static structural applications. However, it should be noted that its residual stress is relatively high and it is not suitable for dynamic load scenarios. When selecting the type, the engineering requirements should be taken into account. The qualifications and certification documents of the suppliers should be strictly reviewed, and regular maintenance should be carried out to extend the service life.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn