- Details

-

EN10255 is the core standard formulated by the European Union for non-alloy steel welded threaded pipes. The full name is "Non-alloy steel tubes suitable for welding, threading and other joining methods". The following is a detailed analysis from three aspects: technical features, application scenarios, and core advantages

I. Technical features

1. Materials and Classification

• Material:Non-alloy quality steel (such as grade S195T, steel grade 1.0026) is adopted, in compliance with EN 10027 standard, and has good weldability and machinability.• Classification: It is divided into two series, Medium and Heavy, based on wall thickness, covering three specified thickness types to meet different pressure-bearing requirements.

2. Dimensions and specifications

• Outer diameter range: 10.2mm - 165.1mm (corresponding to thread dimensions from 1/8" to 6"), meeting the demands from small pipes to large-scale engineering pipelines.•Tolerance control: The standard has strict requirements for dimensional tolerances to ensure the accuracy of thread fit and sealing performance.

3. Key performance requirements

• Mechanical properties: It is necessary to pass tests such as yield strength (≥195 MPa) and tensile strength to ensure structural stability.• Functional tests: including gas-liquid sealing property (Tightness), fire resistance Reaction (Reaction to fire), Durability (Durability) and hazardous substance detection, in compliance with EU building materials regulation CPR (EU) No 305/2011.

• End processing: Multiple pipe end processing options (such as threading, beveling) are provided to adapt to different connection methods.

4. Surface treatment

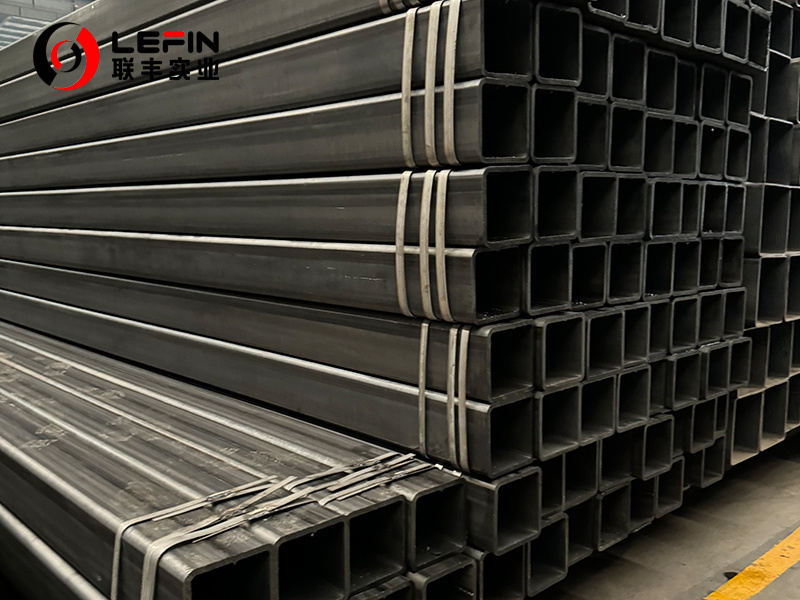

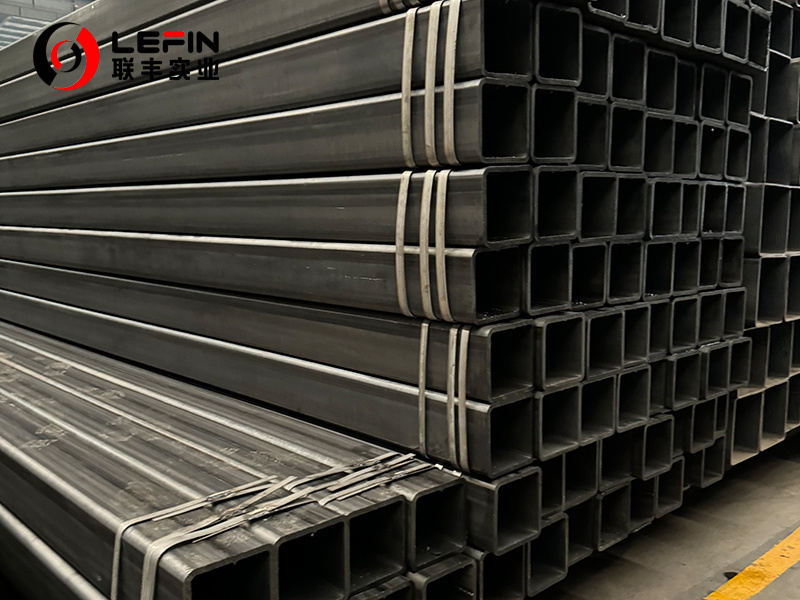

Optional galvanized (anti-rust), clear varnish or black paint coatings are available to enhance corrosion resistance and extend service life (especially in damp or chemical environments).

II. Application scenarios

EN10255 steel pipes, with their high compatibility and reliability, are widely used in the following fields:

1. Architecture and Infrastructure- Pipeline systems for transporting water, gas and fuel (such as heating/cooling networks).

- Building structure support components, curtain wall frames, solar brackets (such as torque tubes for photovoltaic tracking systems).

2. Industrial systems

- Fire protection pipelines (conforming to FM1630/UL852 standards), compressor pipelines, heat exchanger pipelines.

- Oil and gas casing, slit pipe and pile pipe (in accordance with API 5CT/5L standards).

3. Special fields

- Automotive chassis structural components, storage equipment frames.

- Food/pharmaceutical fluid delivery pipelines with high cleanliness requirements (requiring food-grade coating).

III. Core strengths

1. Strong process adaptability

Optimized for welding and threaded connections, it supports multiple processing methods (bending, stamping, cutting), reducing installation complexity.2. Long service life and economy

Galvanization or coating treatment provides excellent rust prevention and reduces maintenance frequency.Standardized production reduces customization costs

3. Compliance and Security

Mandatory CE certification (Mode 3 or Mode 4) requires testing by a notified body (such as NB1922) or factory audits to ensure compliance with EU building product safety regulations.It simultaneously meets multiple national standards such as API, JIS, and ISO, and supports global project procurement.

4. Multi-functional scalability

By adjusting the wall thickness series (medium/heavy-duty) and surface treatment, it can be adapted to a wide range of scenarios from low-pressure water pipes to high-pressure gas pipes.IV. Certification requirements (CE marking)

The export of EN10255 steel pipes to the European Union needs to go through the following procedures

- Test items: Fire resistance reaction, yield strength, sealing performance, durability, and detection of harmful substances.

- Authentication Mode:

- System 3: Notified Body (NB) tests samples and issues certificates;

- System 4: Factory self-testing + signing of Performance Declaration (DoP) + NB review and certification.

- Marking specification: The CE label must include manufacturer information, standard number (EN10255:2015), performance grade and NB organization number.

specification comparison table

Features Medium Series Heavy Series Notes wall thickness standard thicken vailable in three thicknesses outer diameter 10.2-165.1mm 10.2-165.1mm thread size of 1/8" - 6" Yield strength ≥195 MPa ≥215 MPa adjusted according to the grade Applicable scenarios Low-pressure fluid high-pressure/structural support heavy-duty gas pipes summary

EN10255 steel pipes, with their standardized design, high process compatibility and strict safety certification, have become the preferred choice for building and industrial pipelines. Its core value lies in: achieving long-term anti-corrosion through material optimization and galvanizing process; Compatible with multiple connection scenarios such as welding and threading; It meets the mainstream global certifications (CE/API/JIS), and is particularly suitable for engineering projects that need to comply with the EU CPR regulations. When purchasing, pay attention to the wall thickness series and coating type, and select the matching model in combination with the application pressure and environment.

EN10255 STEEL PIPES

Subcategory

Keyword

- Details

-

EN10255 is the core standard formulated by the European Union for non-alloy steel welded threaded pipes. The full name is "Non-alloy steel tubes suitable for welding, threading and other joining methods". The following is a detailed analysis from three aspects: technical features, application scenarios, and core advantages

I. Technical features

1. Materials and Classification

• Material:Non-alloy quality steel (such as grade S195T, steel grade 1.0026) is adopted, in compliance with EN 10027 standard, and has good weldability and machinability.• Classification: It is divided into two series, Medium and Heavy, based on wall thickness, covering three specified thickness types to meet different pressure-bearing requirements.

2. Dimensions and specifications

• Outer diameter range: 10.2mm - 165.1mm (corresponding to thread dimensions from 1/8" to 6"), meeting the demands from small pipes to large-scale engineering pipelines.•Tolerance control: The standard has strict requirements for dimensional tolerances to ensure the accuracy of thread fit and sealing performance.

3. Key performance requirements

• Mechanical properties: It is necessary to pass tests such as yield strength (≥195 MPa) and tensile strength to ensure structural stability.• Functional tests: including gas-liquid sealing property (Tightness), fire resistance Reaction (Reaction to fire), Durability (Durability) and hazardous substance detection, in compliance with EU building materials regulation CPR (EU) No 305/2011.

• End processing: Multiple pipe end processing options (such as threading, beveling) are provided to adapt to different connection methods.

4. Surface treatment

Optional galvanized (anti-rust), clear varnish or black paint coatings are available to enhance corrosion resistance and extend service life (especially in damp or chemical environments).

II. Application scenarios

EN10255 steel pipes, with their high compatibility and reliability, are widely used in the following fields:

1. Architecture and Infrastructure- Pipeline systems for transporting water, gas and fuel (such as heating/cooling networks).

- Building structure support components, curtain wall frames, solar brackets (such as torque tubes for photovoltaic tracking systems).

2. Industrial systems

- Fire protection pipelines (conforming to FM1630/UL852 standards), compressor pipelines, heat exchanger pipelines.

- Oil and gas casing, slit pipe and pile pipe (in accordance with API 5CT/5L standards).

3. Special fields

- Automotive chassis structural components, storage equipment frames.

- Food/pharmaceutical fluid delivery pipelines with high cleanliness requirements (requiring food-grade coating).

III. Core strengths

1. Strong process adaptability

Optimized for welding and threaded connections, it supports multiple processing methods (bending, stamping, cutting), reducing installation complexity.2. Long service life and economy

Galvanization or coating treatment provides excellent rust prevention and reduces maintenance frequency.Standardized production reduces customization costs

3. Compliance and Security

Mandatory CE certification (Mode 3 or Mode 4) requires testing by a notified body (such as NB1922) or factory audits to ensure compliance with EU building product safety regulations.It simultaneously meets multiple national standards such as API, JIS, and ISO, and supports global project procurement.

4. Multi-functional scalability

By adjusting the wall thickness series (medium/heavy-duty) and surface treatment, it can be adapted to a wide range of scenarios from low-pressure water pipes to high-pressure gas pipes.IV. Certification requirements (CE marking)

The export of EN10255 steel pipes to the European Union needs to go through the following procedures

- Test items: Fire resistance reaction, yield strength, sealing performance, durability, and detection of harmful substances.

- Authentication Mode:

- System 3: Notified Body (NB) tests samples and issues certificates;

- System 4: Factory self-testing + signing of Performance Declaration (DoP) + NB review and certification.

- Marking specification: The CE label must include manufacturer information, standard number (EN10255:2015), performance grade and NB organization number.

specification comparison table

Features Medium Series Heavy Series Notes wall thickness standard thicken vailable in three thicknesses outer diameter 10.2-165.1mm 10.2-165.1mm thread size of 1/8" - 6" Yield strength ≥195 MPa ≥215 MPa adjusted according to the grade Applicable scenarios Low-pressure fluid high-pressure/structural support heavy-duty gas pipes summary

EN10255 steel pipes, with their standardized design, high process compatibility and strict safety certification, have become the preferred choice for building and industrial pipelines. Its core value lies in: achieving long-term anti-corrosion through material optimization and galvanizing process; Compatible with multiple connection scenarios such as welding and threading; It meets the mainstream global certifications (CE/API/JIS), and is particularly suitable for engineering projects that need to comply with the EU CPR regulations. When purchasing, pay attention to the wall thickness series and coating type, and select the matching model in combination with the application pressure and environment.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn