- Details

-

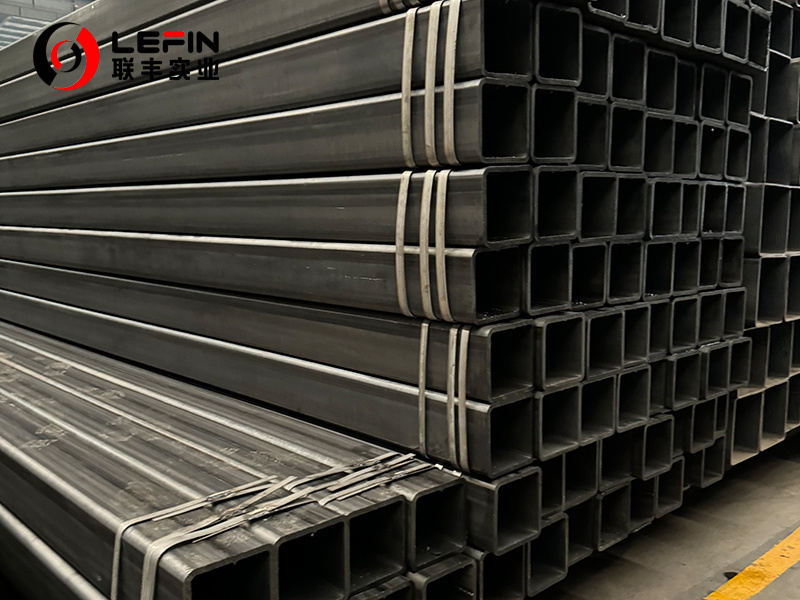

HOLLOW SECTION EN 10219 S235JRH is a cold-formed welded hollow structural profile that conforms to European standards. The following is a detailed introduction:

Standard Overview:

EN 10219 is a European standard for delivery technical conditions and conformity assessment of cold-formed welded hollow structural profiles without subsequent heat treatment for load-bearing structures in buildings such as houses and civil engineering. This standard sets out requirements and assessment methods for the dimensions, chemical composition, mechanical properties, surface conditions, etc. of the products.

Material characteristics:

S235JRH is a low alloy high strength steel. Its yield strength is 235MPa, featuring excellent tensile strength and ductility. It also has outstanding weldability, making it easy to connect with other materials. It is suitable for applications that need to bear large loads.

Chemical composition:

The chemical composition of S235JRH is similar to that of S235JR, mainly including a carbon (C) content not exceeding 0.22%, a silicon (Si) content not exceeding 0.35%, a manganese (Mn) content not exceeding 1.40%, a phosphorus (P) content not exceeding 0.045%, and a sulfur (S) content not exceeding 0.045%. And it may contain trace amounts of copper (Cu) and nickel (Ni).

Mechanical properties:

Its yield strength range is 235-355 mpa, and the tensile strength range is 370-500 mpa. It has certain impact toughness and elongation, which can meet the mechanical requirements of general structural engineering.

Cross-sectional shape and size:

Cross-sectional shapes typically include circular, square, rectangular, etc. According to the EN 10219-2 standard, the maximum outer diameter of circular hollow profiles can reach 2500mm, the maximum external dimensions of square hollow profiles are 500mm×500mm, the maximum external dimensions of rectangular hollow profiles are 500mm×300mm, and the maximum wall thickness is 40mm.

Application fields:

Due to its excellent performance, S235JRH is often used in building steel structures, such as building frames and factory plant construction, and is also suitable for metal welded structures in construction machinery, offshore platforms, etc., providing strength and support for the structure.

Processing and surface treatment:

It is usually made of hot-rolled steel strips through cold forming and welding. After forming, surface treatments such as hot-dip galvanizing can be carried out as required to enhance corrosion resistance and meet the needs of fields such as the fencing industry that have requirements for surface quality and corrosion resistance.

HOLLOW SECTION EN 10219 S235JRH

Subcategory

Keyword

- Details

-

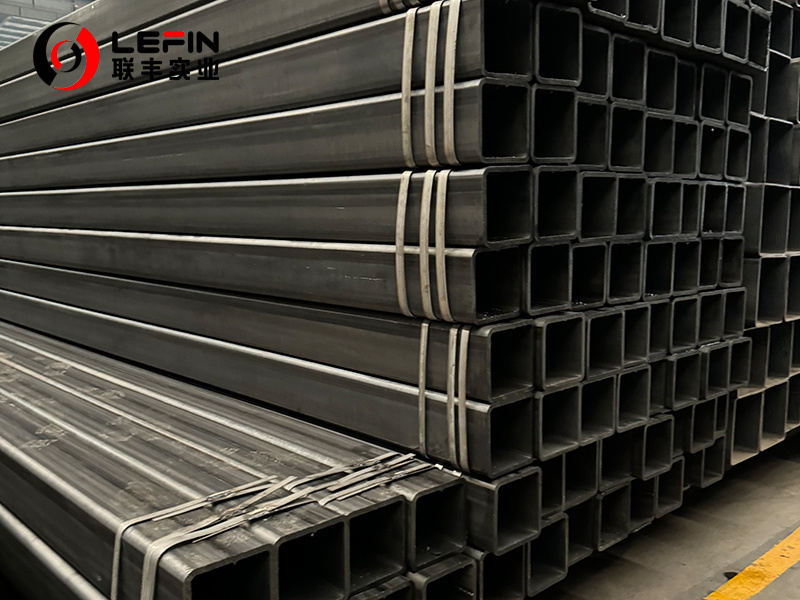

HOLLOW SECTION EN 10219 S235JRH is a cold-formed welded hollow structural profile that conforms to European standards. The following is a detailed introduction:

Standard Overview:

EN 10219 is a European standard for delivery technical conditions and conformity assessment of cold-formed welded hollow structural profiles without subsequent heat treatment for load-bearing structures in buildings such as houses and civil engineering. This standard sets out requirements and assessment methods for the dimensions, chemical composition, mechanical properties, surface conditions, etc. of the products.

Material characteristics:

S235JRH is a low alloy high strength steel. Its yield strength is 235MPa, featuring excellent tensile strength and ductility. It also has outstanding weldability, making it easy to connect with other materials. It is suitable for applications that need to bear large loads.

Chemical composition:

The chemical composition of S235JRH is similar to that of S235JR, mainly including a carbon (C) content not exceeding 0.22%, a silicon (Si) content not exceeding 0.35%, a manganese (Mn) content not exceeding 1.40%, a phosphorus (P) content not exceeding 0.045%, and a sulfur (S) content not exceeding 0.045%. And it may contain trace amounts of copper (Cu) and nickel (Ni).

Mechanical properties:

Its yield strength range is 235-355 mpa, and the tensile strength range is 370-500 mpa. It has certain impact toughness and elongation, which can meet the mechanical requirements of general structural engineering.

Cross-sectional shape and size:

Cross-sectional shapes typically include circular, square, rectangular, etc. According to the EN 10219-2 standard, the maximum outer diameter of circular hollow profiles can reach 2500mm, the maximum external dimensions of square hollow profiles are 500mm×500mm, the maximum external dimensions of rectangular hollow profiles are 500mm×300mm, and the maximum wall thickness is 40mm.

Application fields:

Due to its excellent performance, S235JRH is often used in building steel structures, such as building frames and factory plant construction, and is also suitable for metal welded structures in construction machinery, offshore platforms, etc., providing strength and support for the structure.

Processing and surface treatment:

It is usually made of hot-rolled steel strips through cold forming and welding. After forming, surface treatments such as hot-dip galvanizing can be carried out as required to enhance corrosion resistance and meet the needs of fields such as the fencing industry that have requirements for surface quality and corrosion resistance.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn