- Details

-

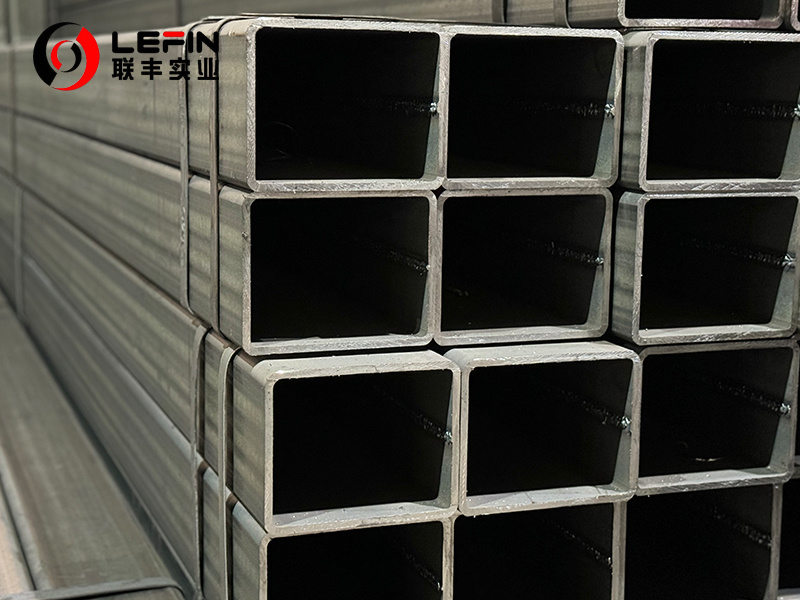

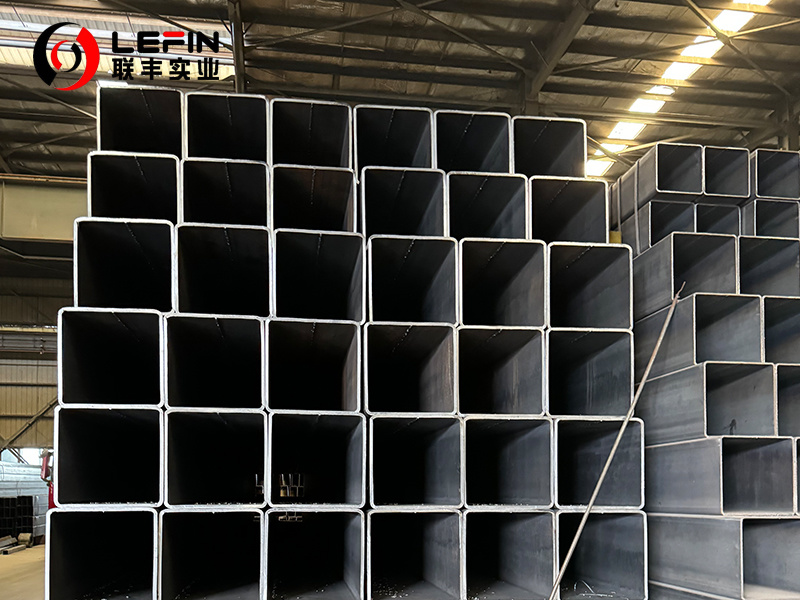

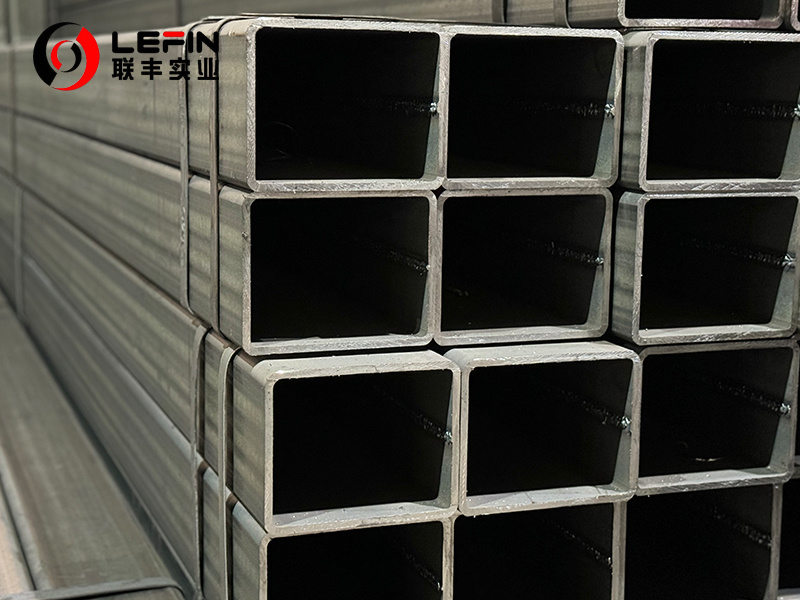

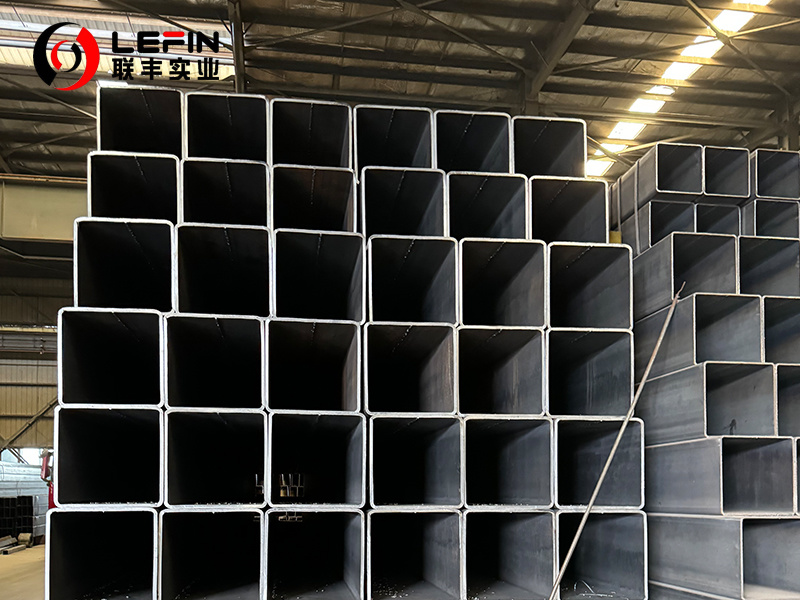

ASTM A500 is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round, square, rectangular, and other shapes. These tubes are used in construction, bridges, general structural applications, and other load-bearing purposes.

Material & Manufacturing

A500 Gr. A, B, C, D(Steel Grades): Different grades with varying mechanical properties.Welded Tubing: Formed from flat-rolled steel and welded longitudinally.

Seamless Tubing: Produced by piercing a solid billet, then cold-drawn to final dimensions.

Cold-Forming Process: Tubing is shaped at room temperature, enhancing strength and surface finish.

Material Requirements

Chemical composition varies slightly between grades but generally includes carbon, manganese, phosphorus, sulfur, and other trace elements.Element Grade A Grade B Grade C Grade D Carbon (C) 0.26(Heat Analysis)

0.30(Product Analysis)0.26(Heat Analysis)

0.30(Product Analysis)0.23(Heat Analysis)

0.27(Product Analysis)0.26(Heat Analysis)

0.30(Product Analysis)Manganese (Mn) 1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)Phosphorus (P) 0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)Sulfur (S) 0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)Copper (Cu) 0.20(Heat Analysis)

0.18(Product Analysis)0.20(Heat Analysis)

0.18(Product Analysis)0.20 (Heat Analysis)

0.18 (Product Analysis)0.20(Heat Analysis)

0.18(Product Analysis)Tensile & Yield Strength:

Grade Tensile Strength (min, ksi) Yield Strength (min, ksi) Elongation (% in 2") A 45 33 (round) / 39 (shapes) 25 B 58 42 (round) / 46 (shapes) 23 C 62 50 21 D 58 36 23

Dimensional Tolerances

Outside Dimensions (OD): Varies by shape (round, square, rectangular).Wall Thickness: Must meet specified minimums; tolerances depend on manufacturing method.

Length: Typically supplied in random or specified cut lengths.

Mechanical Testing

Tensile Test: Determines yield strength, tensile strength, and elongation.Flattening Test (for welded tubes): Ensures weld integrity by flattening a sample without cracking.

Bend Test (optional): Checks ductility.

Applications

Structural Framing (buildings, bridges, towers).Mechanical Components (supports, frames, machinery).

Architectural & Aesthetic Uses (exposed structural elements).

Comparison With Similar Standards

ASTM A501: Hot-formed tubing (less precise tolerances).ASTM A53: General-purpose pipe (not strictly structural).

Key Notes:

Cold-forming enhances strength vs. hot-formed tubes (e.g., ASTM A501).Not intended for high-temperature/pressure service (use ASTM A106 or A53 instead).

Summary

ASTM A500 is a widely used standard for cold-formed welded and seamless carbon steel structural tubing, available in round, square, rectangular, and other shapes. It covers multiple grades (A, B, C, D) with varying chemical compositions and mechanical properties, ensuring suitability for load-bearing applications in construction, bridges, and machinery. The cold-forming process enhances strength and dimensional precision, while stringent testing (tensile, flattening, hardness) guarantees quality. Unlike pressure-rated standards (e.g., ASTM A53), A500 focuses on structural integrity, offering excellent yield and tensile strength with tight tolerances. Proper marking and certification ensure traceability, making it a reliable choice for engineers and architects requiring durable, high-performance steel tubing.

ASTM A500 Carbon Steel Structural Tubing

Subcategory

Keyword

- Details

-

ASTM A500 is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round, square, rectangular, and other shapes. These tubes are used in construction, bridges, general structural applications, and other load-bearing purposes.

Material & Manufacturing

A500 Gr. A, B, C, D(Steel Grades): Different grades with varying mechanical properties.Welded Tubing: Formed from flat-rolled steel and welded longitudinally.

Seamless Tubing: Produced by piercing a solid billet, then cold-drawn to final dimensions.

Cold-Forming Process: Tubing is shaped at room temperature, enhancing strength and surface finish.

Material Requirements

Chemical composition varies slightly between grades but generally includes carbon, manganese, phosphorus, sulfur, and other trace elements.Element Grade A Grade B Grade C Grade D Carbon (C) 0.26(Heat Analysis)

0.30(Product Analysis)0.26(Heat Analysis)

0.30(Product Analysis)0.23(Heat Analysis)

0.27(Product Analysis)0.26(Heat Analysis)

0.30(Product Analysis)Manganese (Mn) 1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)1.35(Heat Analysis)

1.40(Product Analysis)Phosphorus (P) 0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)Sulfur (S) 0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)0.035(Heat Analysis)

0.045(Product Analysis)Copper (Cu) 0.20(Heat Analysis)

0.18(Product Analysis)0.20(Heat Analysis)

0.18(Product Analysis)0.20 (Heat Analysis)

0.18 (Product Analysis)0.20(Heat Analysis)

0.18(Product Analysis)Tensile & Yield Strength:

Grade Tensile Strength (min, ksi) Yield Strength (min, ksi) Elongation (% in 2") A 45 33 (round) / 39 (shapes) 25 B 58 42 (round) / 46 (shapes) 23 C 62 50 21 D 58 36 23

Dimensional Tolerances

Outside Dimensions (OD): Varies by shape (round, square, rectangular).Wall Thickness: Must meet specified minimums; tolerances depend on manufacturing method.

Length: Typically supplied in random or specified cut lengths.

Mechanical Testing

Tensile Test: Determines yield strength, tensile strength, and elongation.Flattening Test (for welded tubes): Ensures weld integrity by flattening a sample without cracking.

Bend Test (optional): Checks ductility.

Applications

Structural Framing (buildings, bridges, towers).Mechanical Components (supports, frames, machinery).

Architectural & Aesthetic Uses (exposed structural elements).

Comparison With Similar Standards

ASTM A501: Hot-formed tubing (less precise tolerances).ASTM A53: General-purpose pipe (not strictly structural).

Key Notes:

Cold-forming enhances strength vs. hot-formed tubes (e.g., ASTM A501).Not intended for high-temperature/pressure service (use ASTM A106 or A53 instead).

Summary

ASTM A500 is a widely used standard for cold-formed welded and seamless carbon steel structural tubing, available in round, square, rectangular, and other shapes. It covers multiple grades (A, B, C, D) with varying chemical compositions and mechanical properties, ensuring suitability for load-bearing applications in construction, bridges, and machinery. The cold-forming process enhances strength and dimensional precision, while stringent testing (tensile, flattening, hardness) guarantees quality. Unlike pressure-rated standards (e.g., ASTM A53), A500 focuses on structural integrity, offering excellent yield and tensile strength with tight tolerances. Proper marking and certification ensure traceability, making it a reliable choice for engineers and architects requiring durable, high-performance steel tubing.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn