- Details

-

Overview

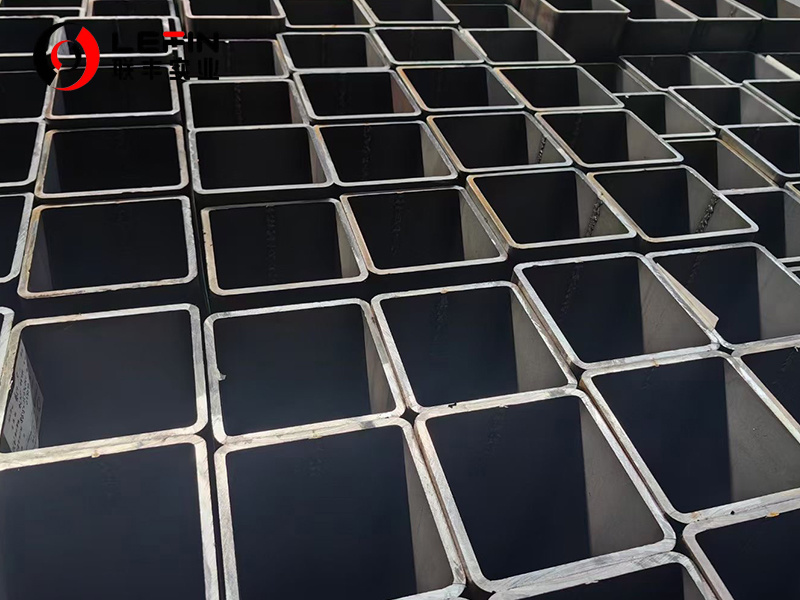

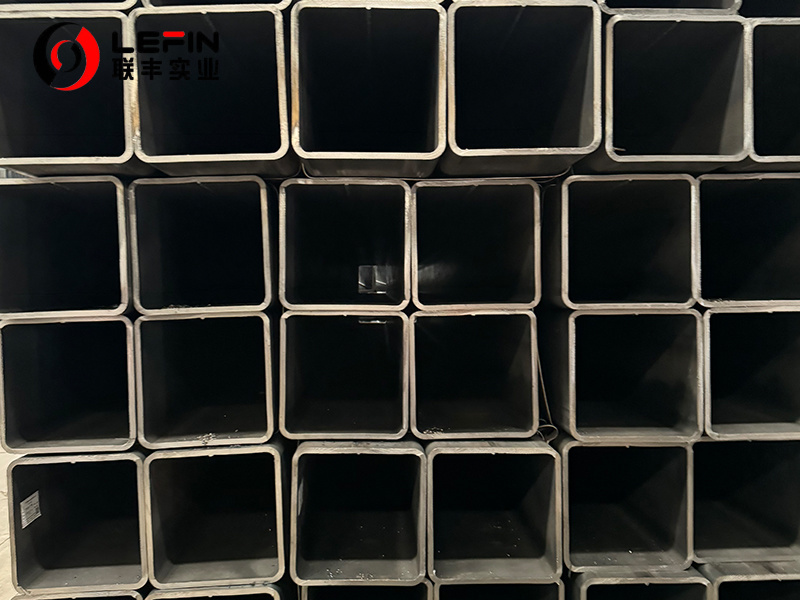

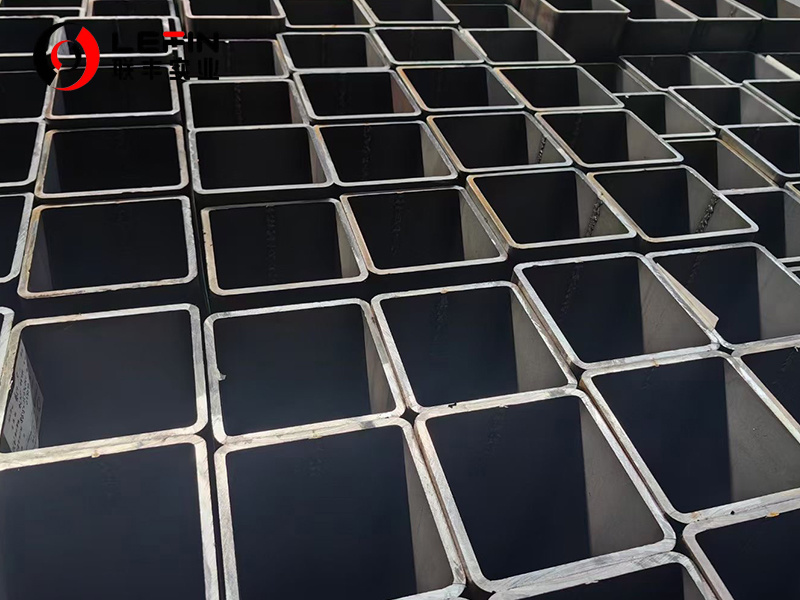

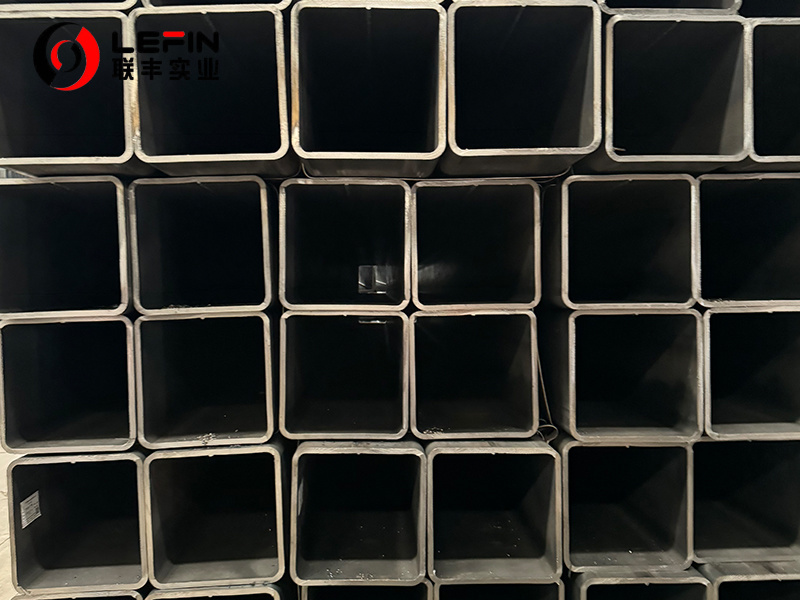

ASTM A501 is a standard specification for hot-formed welded and seamless carbon steel structural tubing used in construction, bridges, and other load-bearing applications. It covers round, square, rectangular, and special-shaped steel tubes designed for structural purposes, offering high strength and weldability.

Key Features:Standard ASTM A501/A501M Material Carbon steel with specified mechanical properties Manufacture Hot-formed weleded and seamless Grade Grade A, Grade B, and Grade C Shape Round, square, rectangular, or special shapes Strength High yield and tensile strength, suitable for structural applications. Round tubing Dimensions Diameters 1 – 48 in. [25 – 1220 mm] and wall thickness of 0.095 – 4.00 in. [2.5 – 100 mm] Free download ASTM A501/A501M – 2021.pdf

Dimension:

Hollow Section Shape (HSS) Outer Diameter Wall Thickness Square and rectangular tubing 1.0 – 16 in [25 – 405 mm] 0.095 – 1.0 in [2.5 – 25 mm] Round tubing 1.0 – 48 in [25 – 1220 mm] 0.095 – 4.0 in [2.5 – 100 mm]

Chemical Composition (Requirements)

Composition, % Grade A Grade B and Grade C Heat Analysis Product Analysis Heat Analysis Product Analysis Carbon, max B 0.26 0.30 0.22 0.26 Manganese, max B - - 1.40 1.45 Phosphorus, max 0.035 0.045 0.030 0.040 Sulfur, max 0.035 0.045 0.020 0.030 Copper, min

(when copper steel is specified)0.20 0.18 0.20 0.18 B For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.60 % by heat analysis and 1.65 % by-product analysis.

Mechanical Properties

Property Wall Thickness

in [mm]Grade A Grade B Grade C Tensile strength, min, psi [MPa] All 58,000 [400] 65000 [448] 70,000 [483] Yield strength, min, psi [MPa] ≤ 1 [25] 39,000 [270] 46,000 [315] 50,000 [345] >1 [25] and ≤ 2 [50] 38,000 [260] 45,000 [310] 49,000 [340] >2 [50] and ≤ 3 [76] 36,500 [250] 42,500 [290] 47,500 [330] >3 [76] and ≤ 4 [100] 35,000 [240] 40,000 [280] 46,000 [315] Elongation, min, % - 25 24 23 Impact Energy min, average, ft/Ibf [J] - 20 [27] 20 [27] 20 [27] min, single, ft/Ibf [J] - 14 [19] 14 [19] 14 [19] Tolerance

Tolerance Shape Outer Diameter >2 in [50 mm] ±1 % all ≤ 2 in [50 mm] ±1/48 in [0.50 mm] Wall Thickness -10 % all Weight -3.5 % – +10% all Length (L) ≤ 7m [22 ft] -1/4 in – +1/2 in [-6 mm – +13 mm] all 7-14m [22-44 ft] -1/4 in – +3/4 in [-6 mm – +19 mm] Straightness Lengths (L) are ft: L/40 (Results in inch);

Lengths (L) are m: 2L (Results in mm);all Squareness of Sides ±1° square and rectangular Radius of Corners each outside corner of the section shall not exceed two times the specified wall thickness. square, rectangular, and special shapes Twist not vary more than 1/12 in [2.1 mm] plus 1/144 in/ft [0.5 mm/m] square, rectangular, and special shapes Concavity and Convexity 1 % from the outside dimension square, rectangular, and special shapes ASTM A501 structural pipe is mostly available in random lengths of 16-22 ft (5-7 m) or 32-44 ft (10-14 m), and can also be supplied in specified lengths.

Applications

ASTM A501 steel tubes are widely used in:Structural frameworks (buildings, bridges, towers)

Construction supports (columns, beams, trusses)

Industrial equipment (scaffolding, machinery frames)

Infrastructure projects (highway guardrails, sign structures)

Advantages

Cost-effective: Lower production costs compared to cold-formed tubes (e.g., ASTM A500).High strength-to-weight ratio: Suitable for heavy-load structures.

Weldability & Formability: Easily welded and fabricated into complex shapes.

Durability: Resistant to deformation under stress.

Comparison With Other Standards

ASTM A500: Cold-formed structural tubing with tighter tolerances but higher cost.ASTM A53: General-purpose pipe (not specifically for structural use).

ASTM A1085: Improved properties and sustainability features.

Conclusion

ASTM A501 steel tubes are a versatile, economical choice for structural applications where high strength and weldability are critical. Their hot-formed manufacturing process ensures robustness, making them ideal for construction and heavy engineering projects.

ASTM A501 Steel Structural Tubing

Subcategory

Keyword

- Details

-

Overview

ASTM A501 is a standard specification for hot-formed welded and seamless carbon steel structural tubing used in construction, bridges, and other load-bearing applications. It covers round, square, rectangular, and special-shaped steel tubes designed for structural purposes, offering high strength and weldability.

Key Features:Standard ASTM A501/A501M Material Carbon steel with specified mechanical properties Manufacture Hot-formed weleded and seamless Grade Grade A, Grade B, and Grade C Shape Round, square, rectangular, or special shapes Strength High yield and tensile strength, suitable for structural applications. Round tubing Dimensions Diameters 1 – 48 in. [25 – 1220 mm] and wall thickness of 0.095 – 4.00 in. [2.5 – 100 mm] Free download ASTM A501/A501M – 2021.pdf

Dimension:

Hollow Section Shape (HSS) Outer Diameter Wall Thickness Square and rectangular tubing 1.0 – 16 in [25 – 405 mm] 0.095 – 1.0 in [2.5 – 25 mm] Round tubing 1.0 – 48 in [25 – 1220 mm] 0.095 – 4.0 in [2.5 – 100 mm]

Chemical Composition (Requirements)

Composition, % Grade A Grade B and Grade C Heat Analysis Product Analysis Heat Analysis Product Analysis Carbon, max B 0.26 0.30 0.22 0.26 Manganese, max B - - 1.40 1.45 Phosphorus, max 0.035 0.045 0.030 0.040 Sulfur, max 0.035 0.045 0.020 0.030 Copper, min

(when copper steel is specified)0.20 0.18 0.20 0.18 B For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.60 % by heat analysis and 1.65 % by-product analysis.

Mechanical Properties

Property Wall Thickness

in [mm]Grade A Grade B Grade C Tensile strength, min, psi [MPa] All 58,000 [400] 65000 [448] 70,000 [483] Yield strength, min, psi [MPa] ≤ 1 [25] 39,000 [270] 46,000 [315] 50,000 [345] >1 [25] and ≤ 2 [50] 38,000 [260] 45,000 [310] 49,000 [340] >2 [50] and ≤ 3 [76] 36,500 [250] 42,500 [290] 47,500 [330] >3 [76] and ≤ 4 [100] 35,000 [240] 40,000 [280] 46,000 [315] Elongation, min, % - 25 24 23 Impact Energy min, average, ft/Ibf [J] - 20 [27] 20 [27] 20 [27] min, single, ft/Ibf [J] - 14 [19] 14 [19] 14 [19] Tolerance

Tolerance Shape Outer Diameter >2 in [50 mm] ±1 % all ≤ 2 in [50 mm] ±1/48 in [0.50 mm] Wall Thickness -10 % all Weight -3.5 % – +10% all Length (L) ≤ 7m [22 ft] -1/4 in – +1/2 in [-6 mm – +13 mm] all 7-14m [22-44 ft] -1/4 in – +3/4 in [-6 mm – +19 mm] Straightness Lengths (L) are ft: L/40 (Results in inch);

Lengths (L) are m: 2L (Results in mm);all Squareness of Sides ±1° square and rectangular Radius of Corners each outside corner of the section shall not exceed two times the specified wall thickness. square, rectangular, and special shapes Twist not vary more than 1/12 in [2.1 mm] plus 1/144 in/ft [0.5 mm/m] square, rectangular, and special shapes Concavity and Convexity 1 % from the outside dimension square, rectangular, and special shapes ASTM A501 structural pipe is mostly available in random lengths of 16-22 ft (5-7 m) or 32-44 ft (10-14 m), and can also be supplied in specified lengths.

Applications

ASTM A501 steel tubes are widely used in:Structural frameworks (buildings, bridges, towers)

Construction supports (columns, beams, trusses)

Industrial equipment (scaffolding, machinery frames)

Infrastructure projects (highway guardrails, sign structures)

Advantages

Cost-effective: Lower production costs compared to cold-formed tubes (e.g., ASTM A500).High strength-to-weight ratio: Suitable for heavy-load structures.

Weldability & Formability: Easily welded and fabricated into complex shapes.

Durability: Resistant to deformation under stress.

Comparison With Other Standards

ASTM A500: Cold-formed structural tubing with tighter tolerances but higher cost.ASTM A53: General-purpose pipe (not specifically for structural use).

ASTM A1085: Improved properties and sustainability features.

Conclusion

ASTM A501 steel tubes are a versatile, economical choice for structural applications where high strength and weldability are critical. Their hot-formed manufacturing process ensures robustness, making them ideal for construction and heavy engineering projects.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn