- Details

-

Overview

Structural steel angles, categorized as equal leg angles and unequal leg angles, are fundamental L-shaped sections widely used in construction, industrial frameworks, and mechanical applications. Their versatility, strength, and ease of fabrication make them essential components in load-bearing structures, bracing systems, and architectural designs. Below is a detailed comparison of their characteristics, applications, and differences.

Equal Leg Angles

Definition

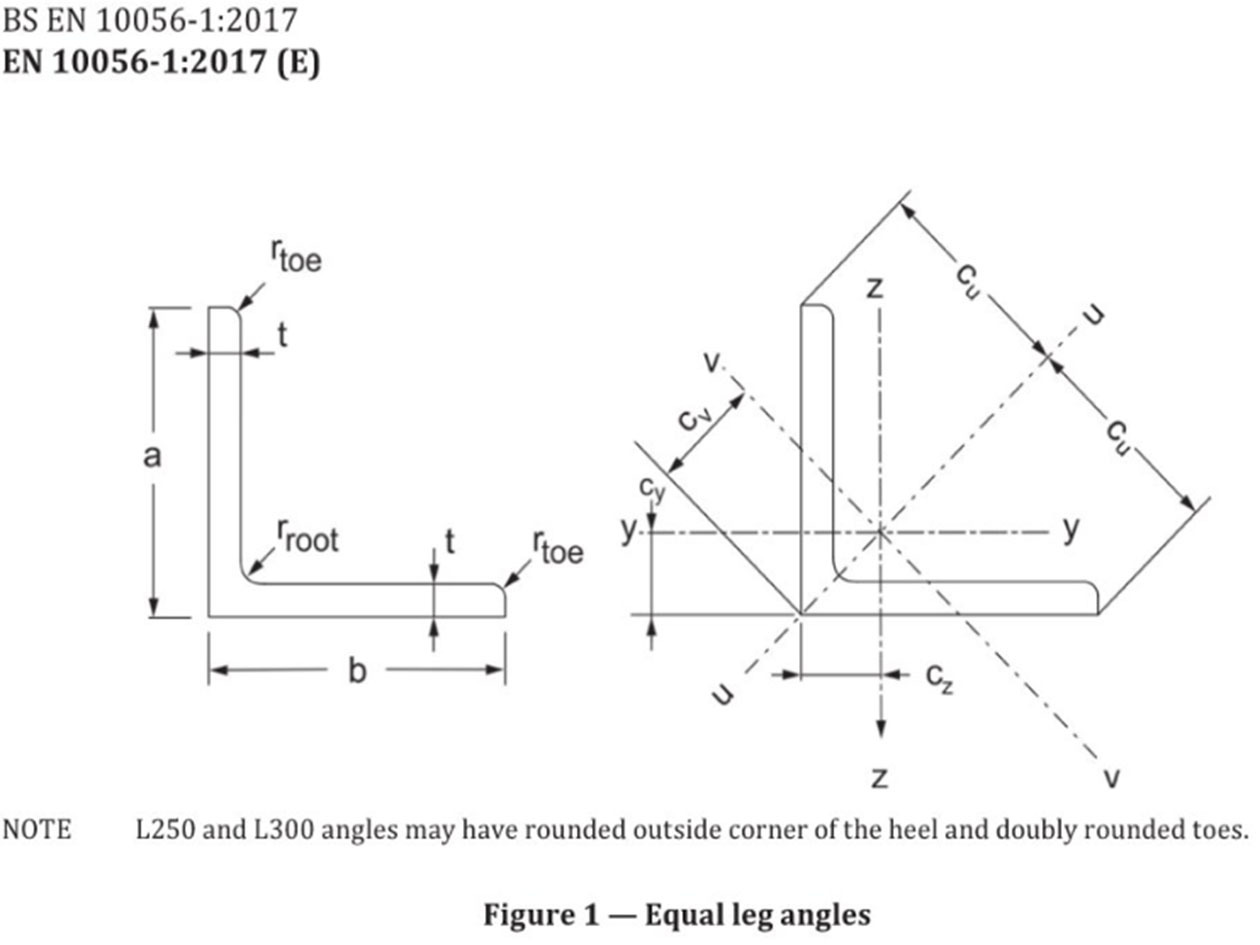

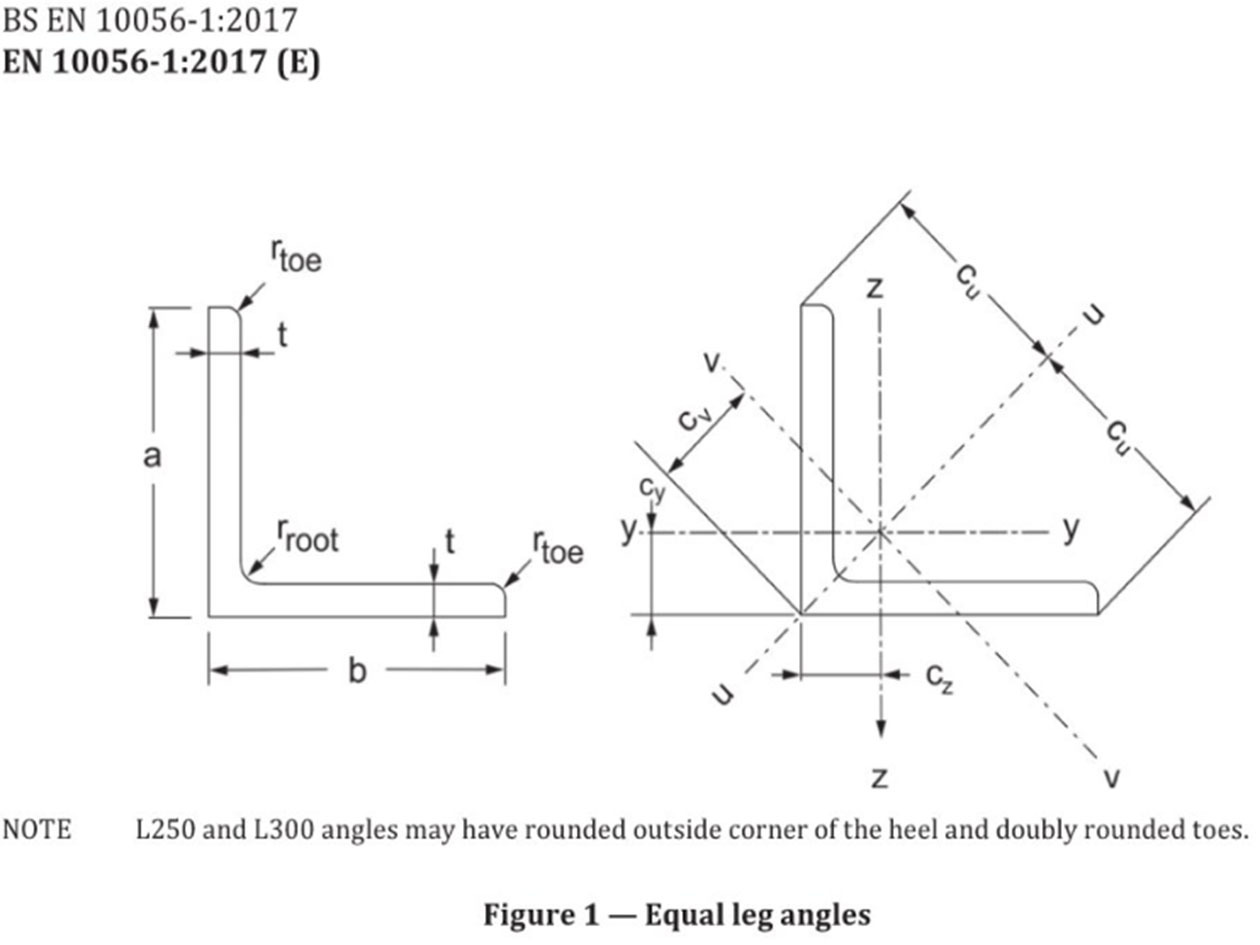

Equal leg angles are structural steel profiles where the lengths of the two legs are identical. This symmetry makes them particularly useful in applications where uniformity and balance are required.Dimensions

● Leg Length: The length of each leg is the same. For example, a 50mm x 50mm equal leg angle means both legs are 50mm in length.

● Thickness: The of thickness the steel can vary depending on the required load-bearing capacity. Typical thicknesses range from a few millimeters to several centimeters for heavier applications.

● Length: Equal leg angles are usually available in standard, lengths such as 6 meters or 12 meters, but they can be cut to custom lengths as needed.

Applications

● Construction: Equal leg angles are commonly used in building frames, trusses, and supports Their. symmetrical shape allows for easy connection to other structural members.

● Fencing: They are often used in the construction of steel fences and gates due to their strength and aesthetic appeal. -Infrastructure ****: In bridges and other infrastructure projects, equal leg angles can be used as supports or reinforcements.

● Mechanical Engineering: They are used in the fabrication of machine frames and supports for equipment.

Advantages

● Ease of Design: The uniformity of equal leg angles simplifies design calculations and makes it easier to create symmetrical structures.

● Versatility: They can be easily welded or bolted to other steel members, making them suitable for a wide range of applications.

● Strength: The equal distribution of material provides good load-bearing capacity in both directions.

Unequal Leg Angles

Definition

Unequal leg angles, as the name suggests, have legs of different lengths. This design allows for greater flexibility in structural applications where different load-bearing requirements exist in different directions.Dimensions

● Leg Lengths: The lengths of the legs vary. For example, a 50mm x 30mm unequal leg angle has one leg that is 50mm long and the other that is 30mm long.

● Thickness: Similar to equal leg angles, the thickness can vary based on the required strength. Thicker sections are used for heavier loads.

● Length: Like equal leg angles, they are available in standard lengths but can be customized.

Applications

● Building Construction: Unequal leg angles are often used in roof trusses, where the longer leg can support more weight or span a greater distance.

● Beams and Columns: In structural frames, unequal leg angles can be used to create beams or columns with different load-bearing capacities in different directions.

● Support Structures: They are used in support structures for machinery or equipment where the load distribution is uneven.

● Infrastructure: In bridge construction, unequal leg angles can be used to create supports that match the varying load requirements of the structure.

Advantages

● Customization: The ability to have different leg lengths allows for more tailored designs to meet specific structural requirements.

● Efficiency: By using unequal leg angles, engineers can optimize the use of material, reducing waste and cost while still achieving the required strength.

● Flexibility: They can be used in a wide range of applications where equal leg angles may not be suitable due to space constraints or load distribution needs.

Common Material And Surface Treatment

Material: Typically hot-rolled carbon steel (e.g., S235JR, S355JR) or stainless steel.Surface: Mill finish, galvanized, or painted for corrosion resistance.

Comparison SummaryFeature

Equal Leg Angle

Unequal Leg Angle

Leg Dimensions L1 = L2 (e.g., 50×50×5 mm) L1 ≠ L2 (e.g., 100×75×6 mm) Symmetry Symmetrical Asymmetrical Load Distribution Uniform Eccentric Typical Use Bracing, general framing Custom supports, uneven loads ● Design Considerations: Equal leg angles are simpler to design with due to their uniformity, while unequal leg angles require more detailed calculations to account for the different load-bearing capacities of each leg.

● Cost: Equal leg angles are generally more cost-effective due to their standardization and ease of production. Unequal leg angles may be more expensive due to the additional manufacturing complexity.

● Strength Distribution: Equal leg angles provide balanced strength in both directions, while unequal leg angles can be designed to provide greater strength in one direction based on the longer leg.

In summary, both equal and unequal leg angles play crucial roles in structural engineering, offering flexibility in design and construction. Equal angles are preferred for balanced load distribution, while unequal angles provide solutions for asymmetric structural needs. The choice between them depends on specific project requirements, including load-bearing capacity, connection methods, and space constraints. Engineers and architects select these angles based on standardized dimensions and material properties to ensure structural integrity and cost efficiency.

Structural Steel Angles: Equal And Unequal Leg Angles

Subcategory

Keyword

- Details

-

Overview

Structural steel angles, categorized as equal leg angles and unequal leg angles, are fundamental L-shaped sections widely used in construction, industrial frameworks, and mechanical applications. Their versatility, strength, and ease of fabrication make them essential components in load-bearing structures, bracing systems, and architectural designs. Below is a detailed comparison of their characteristics, applications, and differences.

Equal Leg Angles

Definition

Equal leg angles are structural steel profiles where the lengths of the two legs are identical. This symmetry makes them particularly useful in applications where uniformity and balance are required.Dimensions

● Leg Length: The length of each leg is the same. For example, a 50mm x 50mm equal leg angle means both legs are 50mm in length.

● Thickness: The of thickness the steel can vary depending on the required load-bearing capacity. Typical thicknesses range from a few millimeters to several centimeters for heavier applications.

● Length: Equal leg angles are usually available in standard, lengths such as 6 meters or 12 meters, but they can be cut to custom lengths as needed.

Applications

● Construction: Equal leg angles are commonly used in building frames, trusses, and supports Their. symmetrical shape allows for easy connection to other structural members.

● Fencing: They are often used in the construction of steel fences and gates due to their strength and aesthetic appeal. -Infrastructure ****: In bridges and other infrastructure projects, equal leg angles can be used as supports or reinforcements.

● Mechanical Engineering: They are used in the fabrication of machine frames and supports for equipment.

Advantages

● Ease of Design: The uniformity of equal leg angles simplifies design calculations and makes it easier to create symmetrical structures.

● Versatility: They can be easily welded or bolted to other steel members, making them suitable for a wide range of applications.

● Strength: The equal distribution of material provides good load-bearing capacity in both directions.

Unequal Leg Angles

Definition

Unequal leg angles, as the name suggests, have legs of different lengths. This design allows for greater flexibility in structural applications where different load-bearing requirements exist in different directions.Dimensions

● Leg Lengths: The lengths of the legs vary. For example, a 50mm x 30mm unequal leg angle has one leg that is 50mm long and the other that is 30mm long.

● Thickness: Similar to equal leg angles, the thickness can vary based on the required strength. Thicker sections are used for heavier loads.

● Length: Like equal leg angles, they are available in standard lengths but can be customized.

Applications

● Building Construction: Unequal leg angles are often used in roof trusses, where the longer leg can support more weight or span a greater distance.

● Beams and Columns: In structural frames, unequal leg angles can be used to create beams or columns with different load-bearing capacities in different directions.

● Support Structures: They are used in support structures for machinery or equipment where the load distribution is uneven.

● Infrastructure: In bridge construction, unequal leg angles can be used to create supports that match the varying load requirements of the structure.

Advantages

● Customization: The ability to have different leg lengths allows for more tailored designs to meet specific structural requirements.

● Efficiency: By using unequal leg angles, engineers can optimize the use of material, reducing waste and cost while still achieving the required strength.

● Flexibility: They can be used in a wide range of applications where equal leg angles may not be suitable due to space constraints or load distribution needs.

Common Material And Surface Treatment

Material: Typically hot-rolled carbon steel (e.g., S235JR, S355JR) or stainless steel.Surface: Mill finish, galvanized, or painted for corrosion resistance.

Comparison SummaryFeature

Equal Leg Angle

Unequal Leg Angle

Leg Dimensions L1 = L2 (e.g., 50×50×5 mm) L1 ≠ L2 (e.g., 100×75×6 mm) Symmetry Symmetrical Asymmetrical Load Distribution Uniform Eccentric Typical Use Bracing, general framing Custom supports, uneven loads ● Design Considerations: Equal leg angles are simpler to design with due to their uniformity, while unequal leg angles require more detailed calculations to account for the different load-bearing capacities of each leg.

● Cost: Equal leg angles are generally more cost-effective due to their standardization and ease of production. Unequal leg angles may be more expensive due to the additional manufacturing complexity.

● Strength Distribution: Equal leg angles provide balanced strength in both directions, while unequal leg angles can be designed to provide greater strength in one direction based on the longer leg.

In summary, both equal and unequal leg angles play crucial roles in structural engineering, offering flexibility in design and construction. Equal angles are preferred for balanced load distribution, while unequal angles provide solutions for asymmetric structural needs. The choice between them depends on specific project requirements, including load-bearing capacity, connection methods, and space constraints. Engineers and architects select these angles based on standardized dimensions and material properties to ensure structural integrity and cost efficiency.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn