- Details

-

Standard Overview

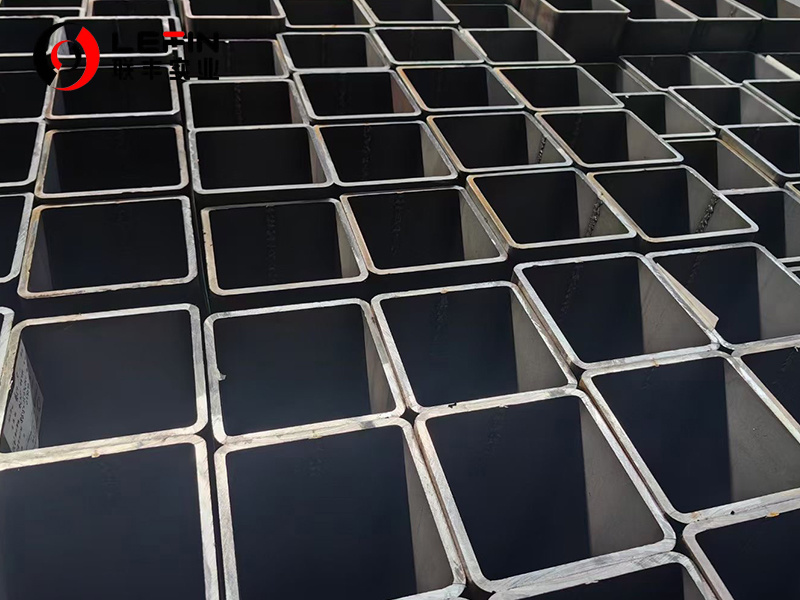

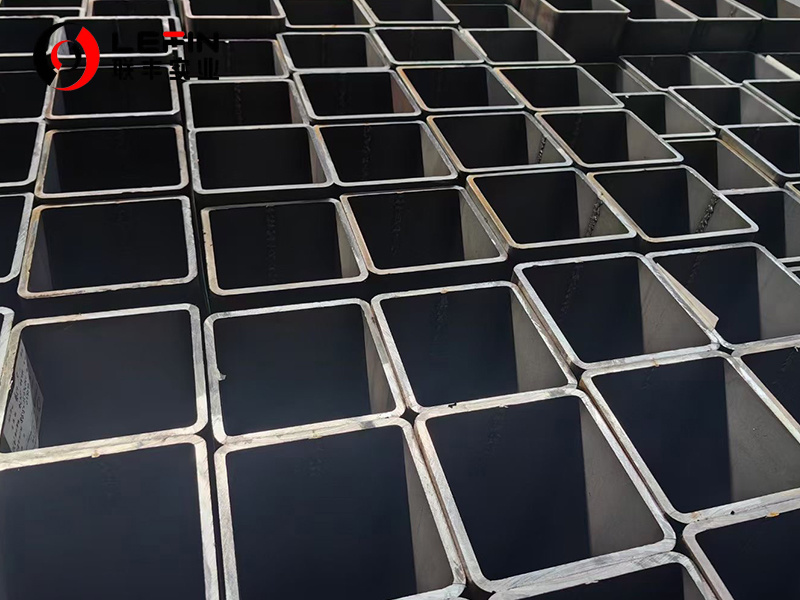

AS 1163 is an Australian Standard that specifies the requirements for cold-formed welded structural steel hollow sections, commonly used in construction, engineering, and industrial applications. The standard covers various grades, including C250, C250L0, C350, C350L0, C450, and C450L0, which differ in yield strength, tensile strength, and impact toughness properties. These pipes are manufactured through cold-forming and electric resistance welding (ERW), ensuring high strength and durability for structural and mechanical uses. This standard ensures compliance with dimensional tolerances, mechanical properties, and testing protocols, making AS 1163 pipes suitable for a wide range of load-bearing applications.Material Grades

The grades C250, C250L0, C350, C350L0, C450, and C450L0 denote different yield strengths and impact toughness properties:"AS / NZS 1163" number of this Standard.

"C" stands for Cold-formed.

The number (250, 350, 450) indicates the minimum yield strength (MPa).

"L0" suffix means the steel is not impact-tested (standard grade), whereas "L0" absence implies impact testing may be required for low-temperature applications.

L = guaranteed impact properties of the material

0 = low temperature impact test at 0°C.

Chemical Composition

As per the AS1163 standard, sampling methods for chemical analysis must be in accordance with ISO 14284. AS/NZS 1050.1 Standard or other procedures that achieve the same, or better, degree of accuracy must be used in order to determine the chemical composition. This is because it is important to have reliable information about the chemical composition in order to make decisions about the safety and quality of the product.Grades

Chemical composition ( cast or product analysis )% max .

C

Si

Mn

P

S

Cr

Mo

Al (Note 3)

Ti

Micro – alloying elements

CE (Note 4)

C250,C250L0 0.12 0.05 0.5 0.03 0.03 0.15 0.1 0.1 0.04 0.03 (Note 5) 0.25 C350,C350L0 0.2 0.45 1.6 0.03 0.03 0.3 0.1 0.1 0.04 0.15 (Note 6) 0.43 C450,C450L0 0.2 0.45 1.7 0.03 0.03 0.5 0.35 0.1 0.04 0.15 (Note 6) 0.43 NOTES :

1 The use of sulphide modification manufacturing techniques for these grades is permitted .

2 The following elements may be present to the limits stated : ( a ) Copper 0.25%. ( b ) Nickel 0.25%.

3 Limits specified are for soluble or total aluminum .

4 Carbon equivalent ( CE ) is calculated from the following equation :

5 Applies to niobium and vanadium only . However , niobium greater than 0.010% is not permitted .

6 Applies to niobium , vanadium and titanium only . However , vanadium greater than 0.10% is not permitted .Mechanical Properties

● Tensile tests, impact tests, and flattening tests are very important when measuring the mechanical properties of AS1163 materials. These tests help determine the material's ability to resist forces that can cause it to break or deform. The tensile test measures a material's ability to withstand pulling forces, while the impact test measures its resistance to shattering forces. The flattening test, meanwhile, assesses a material's ability to resist crushing forces. By assessing the results of these tests, engineers can ensure that these materials will be able to perform as intended in a variety of applications.

● In order to ensure accurate results, it is important to follow the guidelines set out in AS 1391. This standard specifies the rate of straining that should be used when approaching the yield strength, as well as the limits for the conventional straining rate. In addition, the impact test specified in AS 1544.2 must be carried out on each of the three test pieces prepared from each sample. These tests are essential for ensuring the safety and quality of materials.Grade

Minimum yield strength MPa

Minimum tensile strength MPa

Minimum elongation as a proportion of the gauge length of 5.65√S.( see Note )%

Circular hollow sections d0 / t

Rectangular hollow sections b / t , d / t

≤15

>15≤30

>30

≤15

>15≤30

>30

C250,C250L0 250 320 18 20 22 14 16 18 C350,C350L0 350 430 16 18 20 12 14 16 C450,C450L0 450 500 12 14 16 10 12 14 NOTE : These limits apply to the face from which the tensile test is taken . That is , for RHS , the use of b / t or d / t ratio is dependent on which face the test specimen is cut from . For SHS , there is only one ratio ( as b = d ).

CHARPY V – NOTCH IMPACT TEST REQUIREMENTS

Grade

Test temperature ℃

Minimum absorbed energy , J

Size of test piece

10 mm x10 mm

10 mm x 7.5 mm

10mmx5mm

Average of 3 tests

Individual test

Average of 3 tests

Individual test

Average of 3 tests

Individual test

C250L0, C350L0, C450L0 0 27 20 22 16 18 13 The Charpy V-notch impact test is performed on AS 1163 steel pipes to assess their toughness and resistance to brittle fracture, particularly in low-temperature or high-stress environments.

● Key Reasons For Testing:

Material Safety – Ensures the steel can absorb energy without sudden failure (important in seismic zones or cold climates).Structural Integrity – Verifies ductility under impact loads (e.g., bridges, mining equipment, offshore structures).

Grade Compliance – Higher-grade pipes (e.g., C350L0 vs. C350) may require impact testing if used in sub-zero conditions.

Welding & Fabrication – Confirms weld zones and base metal maintain toughness after forming.

● When Is Testing Required?

Non-"L0" grades (e.g., C350, C450) may need testing if specified for low-temperature service (e.g., below 0°C)."L0" grades (e.g., C350L0) are not impact-tested and should be used only in moderate environments.

Dimensions And Tolerances

The Dimensions & Tolerances section of AS 1163 ensures that cold-formed welded steel pipes (CHS, RHS, SHS) meet precise geometric requirements for structural reliability and compatibility in construction and engineering applications. Below is a detailed breakdown of key specifications:● Shape And Mass

Characteristic

Circular hollow sections

Square and rectangular hollow sections

External dimensions ( do , d and b ) ±1%, with a minimum of ±0.5 mm and a maximum of ±10 mm ±1%, with minimum of ±0.5 mm Thickness ( t ) For do ≤406.4 mm :±10% For do >406.4 mm :±10% with a max of ±2 mm ±10% Out – of – roundness ( o ) ±2% for hollow sections having a diameter to thickness ratio not exceeding 100( see Note 1) – Concavity / convexity ( see Note 2) – Max .0.8% or 0.5 mm , whichever is greater Squareness of sides – 90°±1° External corner profile – See Table 5 Twist ( v ) – 2 mm +0.5 mm / m length Straightness ( see Note 3) 0.20% of total length 0.15% of total length NOTES :

1 Where the diameter to thickness ratio exceeds 100, the tolerance on out – of – roundness becomes the subject of agreement between the manufacturer and purchaser .

2 The tolerance on convexity and concavity is independent of the tolerance on external dimensions .

3 The straightness tolerance applies to straightness in any one plane .

● LengthType of length

Range mm

Tolerance

Random length 4000 to 16000 with a range of 2000 per order item 10% of sections supplied may be below the minimum for the ordered range but not less than 75% of the minimum Mill ( or ' unspecified ') length All +100 mm -0 Precision length <6000 +5 mm -0 ≥6000≤10000 +15 mm -0 >10000 +5 mm +1 mm / m -0 NOTE : The enquiry and order shall indicate the type of length required and the length or length range , as appropriate . Alternatively , length tolerances shall be specified at the time of order .

AS 1163's dimensional tolerances ensure interchangeability, structural integrity, and ease of fabrication. Engineers must verify tolerances when specifying pipes for critical applications (e.g., mining, bridges).

Key Advantages And Applications

● Advantages:

High Strength-to-Weight Ratio: Cold-formed construction provides excellent structural strength (yield strengths: 250–450 MPa) while remaining lightweight.

Dimensional Precision: Strict tolerances for diameter, wall thickness, and straightness ensure easy fabrication and compatibility in assemblies.

Durability & Corrosion Resistance: Available in galvanized or painted finishes for harsh environments (e.g., mining, coastal areas).

Cost-Effective Fabrication: Electric resistance welding (ERW) allows efficient production, reducing costs compared to seamless alternatives.

Versatility: Suitable for static and dynamic loads, with options for impact-tested grades (e.g., C350, C450) in low-temperature applications.

● Common Applications:

Construction: Building frames, roof trusses, columns, handrails.

Infrastructure: Bridges, signposts, lighting poles, pipeline supports.

Mining And Industrial: Conveyor systems, machinery guards, hydraulic tubing.

Transportation: Chassis components, trailer frames.

Utilities: Water/gas distribution, electrical conduits.

Summary

AS 1163 steel hollow sections provide a comprehensive solution for structural applications across multiple industries. The standard offers a range of grades (C250-C450) to suit different strength requirements, with precise dimensional tolerances ensuring compatibility in construction projects. The cold-formed ERW manufacturing process delivers cost-effective production while maintaining high quality standards. The inclusion of both standard (L0) and impact-testable grades makes these pipes versatile for various environmental conditions. With strict quality controls and testing protocols, AS 1163 hollow sections are widely recognized in Australia and internationally for their reliability in structural applications, offering engineers a dependable choice for load-bearing components in buildings, infrastructure, and industrial settings.

AS/NZS 1163 Steel Hollow Sections

Subcategory

Keyword

- Details

-

Standard Overview

AS 1163 is an Australian Standard that specifies the requirements for cold-formed welded structural steel hollow sections, commonly used in construction, engineering, and industrial applications. The standard covers various grades, including C250, C250L0, C350, C350L0, C450, and C450L0, which differ in yield strength, tensile strength, and impact toughness properties. These pipes are manufactured through cold-forming and electric resistance welding (ERW), ensuring high strength and durability for structural and mechanical uses. This standard ensures compliance with dimensional tolerances, mechanical properties, and testing protocols, making AS 1163 pipes suitable for a wide range of load-bearing applications.Material Grades

The grades C250, C250L0, C350, C350L0, C450, and C450L0 denote different yield strengths and impact toughness properties:"AS / NZS 1163" number of this Standard.

"C" stands for Cold-formed.

The number (250, 350, 450) indicates the minimum yield strength (MPa).

"L0" suffix means the steel is not impact-tested (standard grade), whereas "L0" absence implies impact testing may be required for low-temperature applications.

L = guaranteed impact properties of the material

0 = low temperature impact test at 0°C.

Chemical Composition

As per the AS1163 standard, sampling methods for chemical analysis must be in accordance with ISO 14284. AS/NZS 1050.1 Standard or other procedures that achieve the same, or better, degree of accuracy must be used in order to determine the chemical composition. This is because it is important to have reliable information about the chemical composition in order to make decisions about the safety and quality of the product.Grades

Chemical composition ( cast or product analysis )% max .

C

Si

Mn

P

S

Cr

Mo

Al (Note 3)

Ti

Micro – alloying elements

CE (Note 4)

C250,C250L0 0.12 0.05 0.5 0.03 0.03 0.15 0.1 0.1 0.04 0.03 (Note 5) 0.25 C350,C350L0 0.2 0.45 1.6 0.03 0.03 0.3 0.1 0.1 0.04 0.15 (Note 6) 0.43 C450,C450L0 0.2 0.45 1.7 0.03 0.03 0.5 0.35 0.1 0.04 0.15 (Note 6) 0.43 NOTES :

1 The use of sulphide modification manufacturing techniques for these grades is permitted .

2 The following elements may be present to the limits stated : ( a ) Copper 0.25%. ( b ) Nickel 0.25%.

3 Limits specified are for soluble or total aluminum .

4 Carbon equivalent ( CE ) is calculated from the following equation :

5 Applies to niobium and vanadium only . However , niobium greater than 0.010% is not permitted .

6 Applies to niobium , vanadium and titanium only . However , vanadium greater than 0.10% is not permitted .Mechanical Properties

● Tensile tests, impact tests, and flattening tests are very important when measuring the mechanical properties of AS1163 materials. These tests help determine the material's ability to resist forces that can cause it to break or deform. The tensile test measures a material's ability to withstand pulling forces, while the impact test measures its resistance to shattering forces. The flattening test, meanwhile, assesses a material's ability to resist crushing forces. By assessing the results of these tests, engineers can ensure that these materials will be able to perform as intended in a variety of applications.

● In order to ensure accurate results, it is important to follow the guidelines set out in AS 1391. This standard specifies the rate of straining that should be used when approaching the yield strength, as well as the limits for the conventional straining rate. In addition, the impact test specified in AS 1544.2 must be carried out on each of the three test pieces prepared from each sample. These tests are essential for ensuring the safety and quality of materials.Grade

Minimum yield strength MPa

Minimum tensile strength MPa

Minimum elongation as a proportion of the gauge length of 5.65√S.( see Note )%

Circular hollow sections d0 / t

Rectangular hollow sections b / t , d / t

≤15

>15≤30

>30

≤15

>15≤30

>30

C250,C250L0 250 320 18 20 22 14 16 18 C350,C350L0 350 430 16 18 20 12 14 16 C450,C450L0 450 500 12 14 16 10 12 14 NOTE : These limits apply to the face from which the tensile test is taken . That is , for RHS , the use of b / t or d / t ratio is dependent on which face the test specimen is cut from . For SHS , there is only one ratio ( as b = d ).

CHARPY V – NOTCH IMPACT TEST REQUIREMENTS

Grade

Test temperature ℃

Minimum absorbed energy , J

Size of test piece

10 mm x10 mm

10 mm x 7.5 mm

10mmx5mm

Average of 3 tests

Individual test

Average of 3 tests

Individual test

Average of 3 tests

Individual test

C250L0, C350L0, C450L0 0 27 20 22 16 18 13 The Charpy V-notch impact test is performed on AS 1163 steel pipes to assess their toughness and resistance to brittle fracture, particularly in low-temperature or high-stress environments.

● Key Reasons For Testing:

Material Safety – Ensures the steel can absorb energy without sudden failure (important in seismic zones or cold climates).Structural Integrity – Verifies ductility under impact loads (e.g., bridges, mining equipment, offshore structures).

Grade Compliance – Higher-grade pipes (e.g., C350L0 vs. C350) may require impact testing if used in sub-zero conditions.

Welding & Fabrication – Confirms weld zones and base metal maintain toughness after forming.

● When Is Testing Required?

Non-"L0" grades (e.g., C350, C450) may need testing if specified for low-temperature service (e.g., below 0°C)."L0" grades (e.g., C350L0) are not impact-tested and should be used only in moderate environments.

Dimensions And Tolerances

The Dimensions & Tolerances section of AS 1163 ensures that cold-formed welded steel pipes (CHS, RHS, SHS) meet precise geometric requirements for structural reliability and compatibility in construction and engineering applications. Below is a detailed breakdown of key specifications:● Shape And Mass

Characteristic

Circular hollow sections

Square and rectangular hollow sections

External dimensions ( do , d and b ) ±1%, with a minimum of ±0.5 mm and a maximum of ±10 mm ±1%, with minimum of ±0.5 mm Thickness ( t ) For do ≤406.4 mm :±10% For do >406.4 mm :±10% with a max of ±2 mm ±10% Out – of – roundness ( o ) ±2% for hollow sections having a diameter to thickness ratio not exceeding 100( see Note 1) – Concavity / convexity ( see Note 2) – Max .0.8% or 0.5 mm , whichever is greater Squareness of sides – 90°±1° External corner profile – See Table 5 Twist ( v ) – 2 mm +0.5 mm / m length Straightness ( see Note 3) 0.20% of total length 0.15% of total length NOTES :

1 Where the diameter to thickness ratio exceeds 100, the tolerance on out – of – roundness becomes the subject of agreement between the manufacturer and purchaser .

2 The tolerance on convexity and concavity is independent of the tolerance on external dimensions .

3 The straightness tolerance applies to straightness in any one plane .

● LengthType of length

Range mm

Tolerance

Random length 4000 to 16000 with a range of 2000 per order item 10% of sections supplied may be below the minimum for the ordered range but not less than 75% of the minimum Mill ( or ' unspecified ') length All +100 mm -0 Precision length <6000 +5 mm -0 ≥6000≤10000 +15 mm -0 >10000 +5 mm +1 mm / m -0 NOTE : The enquiry and order shall indicate the type of length required and the length or length range , as appropriate . Alternatively , length tolerances shall be specified at the time of order .

AS 1163's dimensional tolerances ensure interchangeability, structural integrity, and ease of fabrication. Engineers must verify tolerances when specifying pipes for critical applications (e.g., mining, bridges).

Key Advantages And Applications

● Advantages:

High Strength-to-Weight Ratio: Cold-formed construction provides excellent structural strength (yield strengths: 250–450 MPa) while remaining lightweight.

Dimensional Precision: Strict tolerances for diameter, wall thickness, and straightness ensure easy fabrication and compatibility in assemblies.

Durability & Corrosion Resistance: Available in galvanized or painted finishes for harsh environments (e.g., mining, coastal areas).

Cost-Effective Fabrication: Electric resistance welding (ERW) allows efficient production, reducing costs compared to seamless alternatives.

Versatility: Suitable for static and dynamic loads, with options for impact-tested grades (e.g., C350, C450) in low-temperature applications.

● Common Applications:

Construction: Building frames, roof trusses, columns, handrails.

Infrastructure: Bridges, signposts, lighting poles, pipeline supports.

Mining And Industrial: Conveyor systems, machinery guards, hydraulic tubing.

Transportation: Chassis components, trailer frames.

Utilities: Water/gas distribution, electrical conduits.

Summary

AS 1163 steel hollow sections provide a comprehensive solution for structural applications across multiple industries. The standard offers a range of grades (C250-C450) to suit different strength requirements, with precise dimensional tolerances ensuring compatibility in construction projects. The cold-formed ERW manufacturing process delivers cost-effective production while maintaining high quality standards. The inclusion of both standard (L0) and impact-testable grades makes these pipes versatile for various environmental conditions. With strict quality controls and testing protocols, AS 1163 hollow sections are widely recognized in Australia and internationally for their reliability in structural applications, offering engineers a dependable choice for load-bearing components in buildings, infrastructure, and industrial settings.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn