- Details

-

Overview

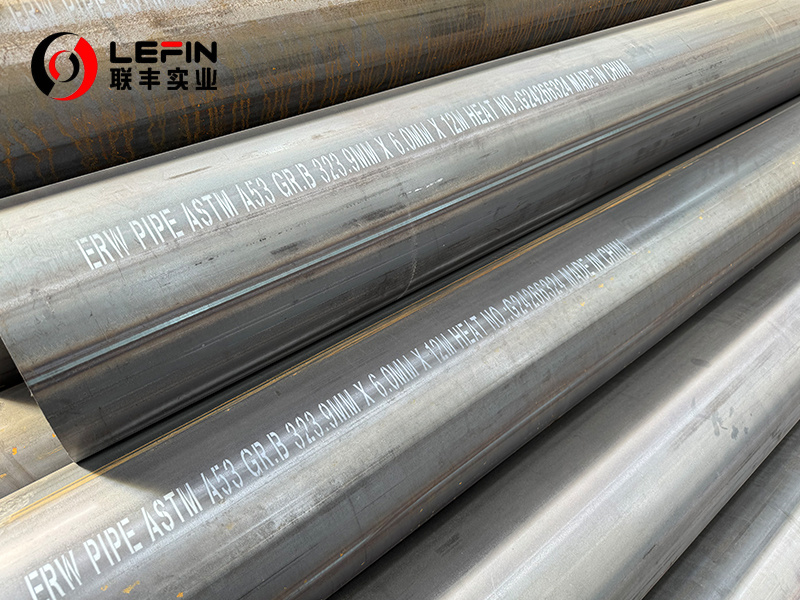

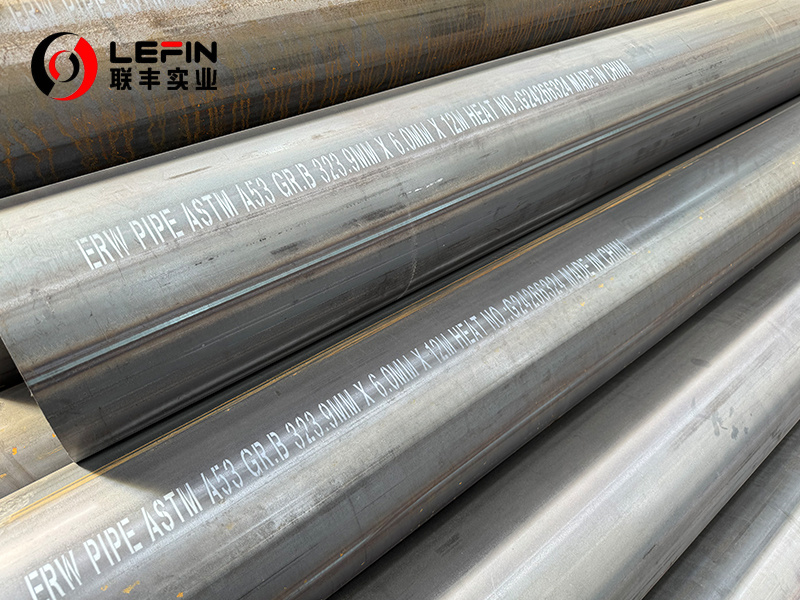

ASTM A53 is a standard specification for carbon steel pipe published by the American Society for Testing and Materials (ASTM). It covers Seamless and Welded, Black and Hot-Dipped Galvanized steel pipes with nominal wall thickness, widely used in structural applications, pressure piping, and mechanical systems.

Types

● Type S (Seamless): These pipes have no weld seams and are produced by extrusion. They are ideal for applications requiring high strength and durability, such as high-pressure systems.

● Type E (Electric Resistance Welded): Manufactured by welding the steel longitudinally, these pipes can be cold-expanded or non-expanded. The weld seam of Grade B Type E pipes is heat-treated to enhance properties.

● Type F (Furnace Butt-Welded): These pipes are produced by continuous welding in a furnace. They are suitable for lower pressure applications but not intended for flanging.

Grades

● Grade A: Softer and more malleable, with a tensile strength of 48,000 psi (330 MPa) and a yield strength of 30,000 psi (205 MPa). It is suitable for low-pressure applications.

● Grade B: Offers higher tensile strength (60,000 psi, or 415 MPa) and yield strength (35,000 psi, or 240 MPa), making it ideal for high-pressure applications.

Dimensions And Sizes

Nominal Pipe Size (NPS): Ranges from 1/8" to 26" (larger sizes typically welded).Schedule Numbers: Common schedules include Sch 40, Sch 80, Sch 160, indicating wall thickness.

Manufacturing Process

The production process includes selecting high-quality steel, forming it into shape, welding (for ERW pipes), cooling, sizing, and rigorous testing. For galvanized pipes, a hot-dip zinc coating is applied to enhance corrosion resistance.● Seamless (Type S): Made by piercing a solid billet, then extruding or rolling it into a pipe.

● Welded (Type E & F):

ERW (Type E): Formed by rolling steel coil and welding the seam electrically.Furnace-Welded (Type F): Made by heating and forging the edges together.

Surface Treatment And Coating

● Black (Bare): No coating, used for general purposes.

● Galvanized (G): Zinc-coated for corrosion resistance (common in plumbing).

Chemical Composition

Composition, max, % Carbon Manganese Phosphorus Sulfur Sulfur A Nickel A Chromium A Molybdenum A Vanadium A Type S (seamless pipe) Grade A 0.25 0.95 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Grade B 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Type E (electric-resistance-welded) Grade A 0.25 0.95 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Grade B 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Type F (furnace-welded pipe) Grade A 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08

A The combination of these five elements shall not exceed 1.00 %.● The chemical composition varies by grade. Grade B typically has a higher carbon content compared to Grade A, contributing to its increased strength. The steel used for both seamless and welded pipes must be produced via open hearth, electric furnace, or basic oxygen process.

Mechanical Properties

Property

Grade A

Grade B

Tensile Strength

≥330 MPa (48,000 psi)

≥415 MPa (60,000 psi)

Yield Strength

≥205 MPa (30,000 psi)

≥240 MPa (35,000 psi)

Elongation (%)

≥35% (if wall ≤0.75")

≥30% (if wall ≤0.75")

Testing And Inspection

All ASTM A53 pipes undergo hydrostatic testing to ensure their integrity. Additionally, tensile tests are conducted for certain sizes to verify mechanical properties.● Hydrostatic Testing: Required for pressure applications.

● Non-Destructive Testing (NDT): Ultrasonic or Eddy Current for welded pipes.

● Bend Test & Flattening Test: For ductility verification.

Applications

ASTM A53 pipes are versatile and used in a wide range of applications, including:● Plumbing systems

● Water and gas conveyance

● Structural applications

● HVAC systems

● Fire sprinkler systems

Advantages

● Cost-effective compared to stainless steel or alloy pipes.● Good weldability & machinability.

● Widely available in multiple sizes and schedules.

Conclusion

ASTM A53 pipe is a versatile, economical carbon steel pipe suitable for low-to-medium pressure applications, available in seamless and welded forms. Its Grade B variant is particularly popular in industrial and construction sectors due to its higher strength and durability.

ASTM A53 Pipes

Subcategory

Keyword

- Details

-

Overview

ASTM A53 is a standard specification for carbon steel pipe published by the American Society for Testing and Materials (ASTM). It covers Seamless and Welded, Black and Hot-Dipped Galvanized steel pipes with nominal wall thickness, widely used in structural applications, pressure piping, and mechanical systems.

Types

● Type S (Seamless): These pipes have no weld seams and are produced by extrusion. They are ideal for applications requiring high strength and durability, such as high-pressure systems.

● Type E (Electric Resistance Welded): Manufactured by welding the steel longitudinally, these pipes can be cold-expanded or non-expanded. The weld seam of Grade B Type E pipes is heat-treated to enhance properties.

● Type F (Furnace Butt-Welded): These pipes are produced by continuous welding in a furnace. They are suitable for lower pressure applications but not intended for flanging.

Grades

● Grade A: Softer and more malleable, with a tensile strength of 48,000 psi (330 MPa) and a yield strength of 30,000 psi (205 MPa). It is suitable for low-pressure applications.

● Grade B: Offers higher tensile strength (60,000 psi, or 415 MPa) and yield strength (35,000 psi, or 240 MPa), making it ideal for high-pressure applications.

Dimensions And Sizes

Nominal Pipe Size (NPS): Ranges from 1/8" to 26" (larger sizes typically welded).Schedule Numbers: Common schedules include Sch 40, Sch 80, Sch 160, indicating wall thickness.

Manufacturing Process

The production process includes selecting high-quality steel, forming it into shape, welding (for ERW pipes), cooling, sizing, and rigorous testing. For galvanized pipes, a hot-dip zinc coating is applied to enhance corrosion resistance.● Seamless (Type S): Made by piercing a solid billet, then extruding or rolling it into a pipe.

● Welded (Type E & F):

ERW (Type E): Formed by rolling steel coil and welding the seam electrically.Furnace-Welded (Type F): Made by heating and forging the edges together.

Surface Treatment And Coating

● Black (Bare): No coating, used for general purposes.

● Galvanized (G): Zinc-coated for corrosion resistance (common in plumbing).

Chemical Composition

Composition, max, % Carbon Manganese Phosphorus Sulfur Sulfur A Nickel A Chromium A Molybdenum A Vanadium A Type S (seamless pipe) Grade A 0.25 0.95 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Grade B 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Type E (electric-resistance-welded) Grade A 0.25 0.95 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Grade B 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08 Type F (furnace-welded pipe) Grade A 0.30 1.20 0.05 0.045 0.40 0.40 0.40 0.15 0.08

A The combination of these five elements shall not exceed 1.00 %.● The chemical composition varies by grade. Grade B typically has a higher carbon content compared to Grade A, contributing to its increased strength. The steel used for both seamless and welded pipes must be produced via open hearth, electric furnace, or basic oxygen process.

Mechanical Properties

Property

Grade A

Grade B

Tensile Strength

≥330 MPa (48,000 psi)

≥415 MPa (60,000 psi)

Yield Strength

≥205 MPa (30,000 psi)

≥240 MPa (35,000 psi)

Elongation (%)

≥35% (if wall ≤0.75")

≥30% (if wall ≤0.75")

Testing And Inspection

All ASTM A53 pipes undergo hydrostatic testing to ensure their integrity. Additionally, tensile tests are conducted for certain sizes to verify mechanical properties.● Hydrostatic Testing: Required for pressure applications.

● Non-Destructive Testing (NDT): Ultrasonic or Eddy Current for welded pipes.

● Bend Test & Flattening Test: For ductility verification.

Applications

ASTM A53 pipes are versatile and used in a wide range of applications, including:● Plumbing systems

● Water and gas conveyance

● Structural applications

● HVAC systems

● Fire sprinkler systems

Advantages

● Cost-effective compared to stainless steel or alloy pipes.● Good weldability & machinability.

● Widely available in multiple sizes and schedules.

Conclusion

ASTM A53 pipe is a versatile, economical carbon steel pipe suitable for low-to-medium pressure applications, available in seamless and welded forms. Its Grade B variant is particularly popular in industrial and construction sectors due to its higher strength and durability.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn