- Details

-

Scope And Purpose

Standard Title: Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

Developed by: ASTM International (Subcommittee A01.09 on Structural Steel)

Primary Use: Structural applications requiring high strength, precision tolerances, and weldability.

Key Advantages Over A500:

Higher strength-to-weight ratio.Improved dimensional consistency.

Better weldability and ductility for seismic and dynamic loading.

Chemical Composition

The chemical composition of ASTM A1085 Element Carbon (C), max for heat analysis : 0.26%

for product analysis : 0.30%

Manganese (Mn), max for heat analysis : 1.35%

for product analysis : 1.40%

Phosphorus (P), max for heat analysis : 0.035%

for product analysis : 0.045%

Sulfur (S), max for heat analysis : 0.035%

for product analysis : 0.045%

Aluminum(Al), min for heat analysis: 0.015% acid soluble OR

-

Silicon(Si), max for heat analysis : 0.04%

for product analysis : 0.07%

Notes: For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.50% by heat analysis and 1.60% by product analysis.

Mechanical Properties

Property

ASTM A1085 Requirements

Yield Strength (min) 50 ksi (345 MPa) – 70 ksi (485 MPa)

Tensile Strength (min) 65 ksi (450 MPa)

Elongation (min, %) 21% (depends on wall thickness)

Notes: The minimum elongation values specified apply only to tests performed prior to shipment of the tubing.

Manufacturing Process

Cold Forming & Welding

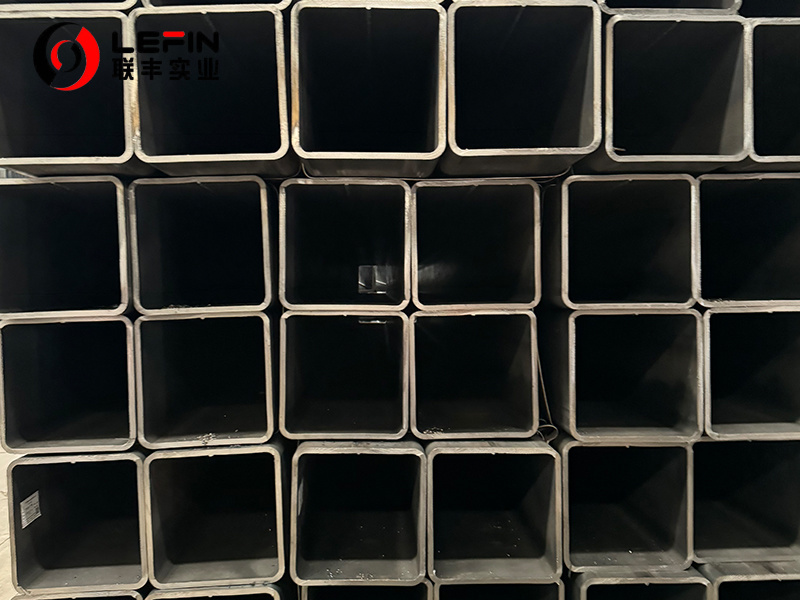

Forming: Flat steel is roll-formed into round, square, or rectangular shapes.

Welding: High-frequency electric resistance welding (ERW) or laser welding ensures a seamless, high-strength joint.

Sizing & Shaping: Cold-worked to achieve tight tolerances (±0.5% on dimensions).

Impact Toughness (Charpy V-Notch)

Requires all HSS to meet a minimum Charpy V-notch value of 25 ft-lb at 40°F. This makes it suitable for structures subject to fatigue and low-temperature applications.

Applications

High-Rise Buildings: Lighter columns with higher load capacity.Bridges: Improved fatigue resistance.

Seismic Zones: Better energy absorption during earthquakes.

Architectural Exposed Steel: Aesthetic appeal with structural integrity.

Conclusion

ASTM A1085 represents an advanced evolution of HSS standards, offering superior strength, precision, and weldability compared to older specs like A500. It is increasingly preferred in modern steel construction, particularly where seismic resilience, lightweight efficiency, and fabrication ease are critical.

ASTM A1085 HSS

Subcategory

Keyword

- Details

-

Scope And Purpose

Standard Title: Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

Developed by: ASTM International (Subcommittee A01.09 on Structural Steel)

Primary Use: Structural applications requiring high strength, precision tolerances, and weldability.

Key Advantages Over A500:

Higher strength-to-weight ratio.Improved dimensional consistency.

Better weldability and ductility for seismic and dynamic loading.

Chemical Composition

The chemical composition of ASTM A1085 Element Carbon (C), max for heat analysis : 0.26%

for product analysis : 0.30%

Manganese (Mn), max for heat analysis : 1.35%

for product analysis : 1.40%

Phosphorus (P), max for heat analysis : 0.035%

for product analysis : 0.045%

Sulfur (S), max for heat analysis : 0.035%

for product analysis : 0.045%

Aluminum(Al), min for heat analysis: 0.015% acid soluble OR

-

Silicon(Si), max for heat analysis : 0.04%

for product analysis : 0.07%

Notes: For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.50% by heat analysis and 1.60% by product analysis.

Mechanical Properties

Property

ASTM A1085 Requirements

Yield Strength (min) 50 ksi (345 MPa) – 70 ksi (485 MPa)

Tensile Strength (min) 65 ksi (450 MPa)

Elongation (min, %) 21% (depends on wall thickness)

Notes: The minimum elongation values specified apply only to tests performed prior to shipment of the tubing.

Manufacturing Process

Cold Forming & Welding

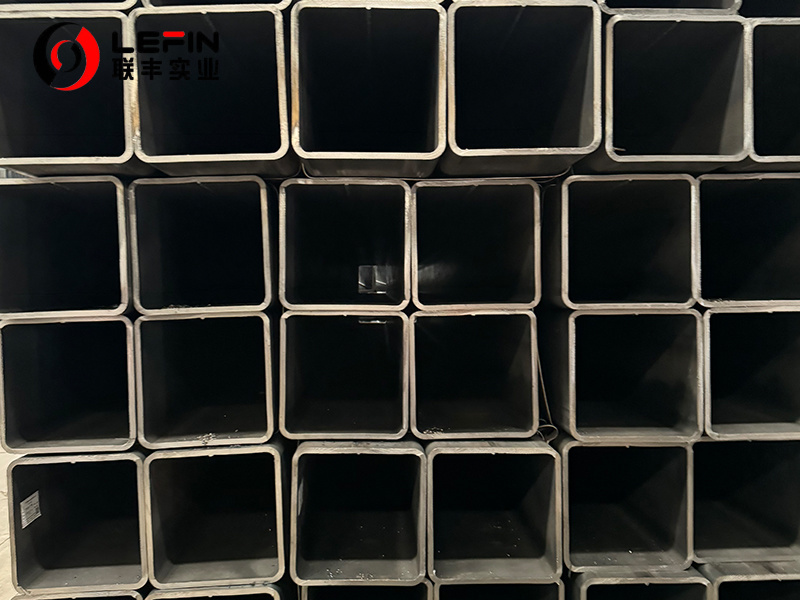

Forming: Flat steel is roll-formed into round, square, or rectangular shapes.

Welding: High-frequency electric resistance welding (ERW) or laser welding ensures a seamless, high-strength joint.

Sizing & Shaping: Cold-worked to achieve tight tolerances (±0.5% on dimensions).

Impact Toughness (Charpy V-Notch)

Requires all HSS to meet a minimum Charpy V-notch value of 25 ft-lb at 40°F. This makes it suitable for structures subject to fatigue and low-temperature applications.

Applications

High-Rise Buildings: Lighter columns with higher load capacity.Bridges: Improved fatigue resistance.

Seismic Zones: Better energy absorption during earthquakes.

Architectural Exposed Steel: Aesthetic appeal with structural integrity.

Conclusion

ASTM A1085 represents an advanced evolution of HSS standards, offering superior strength, precision, and weldability compared to older specs like A500. It is increasingly preferred in modern steel construction, particularly where seismic resilience, lightweight efficiency, and fabrication ease are critical.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn