- Details

-

Standard And Material Specification

Standard: EN 10210

A European standard specifying the technical delivery conditions for hot-finished hollow structural sections (HSS) made of non-alloy and fine-grain steels.Grade: S355J2H

S355: Indicates minimum yield strength of 355 MPa at room temperature.J2: Charpy V-notch impact toughness requirement at -20°C (27 Joules minimum).

H: Denotes hot-finished production (as opposed to cold-formed).

Chemical PropertiesSteel Grade C Maximum Mn Maximum Si Maximum P Maximum S Maximum N Maximum S235JRH 0.17 1.40 – 0.040 0.040 0.009 S355J0H 0.22 1.60 0.55 0.035 0.035 0.009 S275J2H 0.20 1.50 – 0.030 0.030 – S355J2H 0.22 1.60 0.55 0.030 0.030 – S275J0H 0.20 1.50 – 0.035 0.035 0.009 S355K2H 0.22 1.60 0.55 0.030 0.030 – Carbon (C) – Enhances hardness and strength but reduces ductility and weldability (controlled to ≤0.22% for balance).

Silicon (Si) – Improves strength and deoxidation during steelmaking (limited to ≤0.55% to avoid brittleness).

Manganese (Mn) – Increases strength and hardenability while improving hot workability (≤1.6%).

Phosphorus (P) & Sulfur (S) – Harmful impurities (≤0.030% each); reduce toughness and promote cracking.

Key Impact: Elements are balanced to achieve optimal mechanical properties (strength, weldability, impact resistance) for structural applications.

Mechanical Properties

EN 10210

Mechanical Strength Impact Energy Yield Strength

(WT≤16mm)

Elongation (%)

(WT≤40mm)

Tensile Strength

(WT≤3mm)

Test Temperature in celsius -20 0 20 S355J2H 355 22 510-680 27 – – S275J0H 275 23 430-580 – 27 – S275J2H 275 23 430-580 27 – – S235JRH 235 26 360-510 – – 27 S355J0H 355 22 510-680 – 27 – S355K2H 355 22 510-680 40 – – Yield Strength (≥355 MPa) – Indicates the stress at which permanent deformation begins; ensures structural stability under load.

Tensile Strength (510–680 MPa) – Measures maximum stress before failure; guarantees resistance to breaking under tension.

Elongation (≥22%) – Reflects ductility; higher values mean better formability and crack resistance.

Charpy Impact (≥27 J at -20°C) – Evaluates toughness in cold environments; critical for shock/fracture resistance.

Key Impact: These properties ensure the pipe can withstand heavy loads, dynamic forces, and low temperatures without failure.

Manufacturing Process

Raw Material Preparation: High-quality steel slabs or billets with the specified chemical composition for S355J2H are selected.Heating: The steel is heated to around 1100–1200°C to make it ductile for shaping.

Rolling: The heated steel is rolled through specialized mills to form the rectangular hollow sections, ensuring precise dimensions and uniform wall thickness.

Cooling and Straightening: The pipe is cooled gradually to avoid internal stresses and then straightened if necessary.

Inspection and Testing: The finished pipe undergoes dimensional checks, non-destructive testing (e.g., ultrasonic), and mechanical property tests to ensure compliance with EN 10210 standards.

Surface Treatment (Optional): The pipe may be painted or galvanized to enhance corrosion resistance.

Packaging and Storage: The pipes are packaged and stored for shipment.

Applications

Structural Engineering: Building frames, bridges, and offshore platforms.Mechanical Components: Heavy machinery, load-bearing parts.

Infrastructure: Pipelines, support columns, and crane booms.

Advantages

High Strength-to-Weight Ratio: Suitable for heavy-load applications.Good Weldability: Preheating may be required for thick sections.

Impact Resistance: Reliable performance in low-temperature environments.

In summary, EN 10210 S355J2H is a high-strength carbon steel pipe offering excellent mechanical properties and impact resistance. Its hot-finished production ensures superior quality for structural applications in construction, machinery, and infrastructure. With certified performance and cost efficiency, it's a reliable choice for demanding engineering projects.

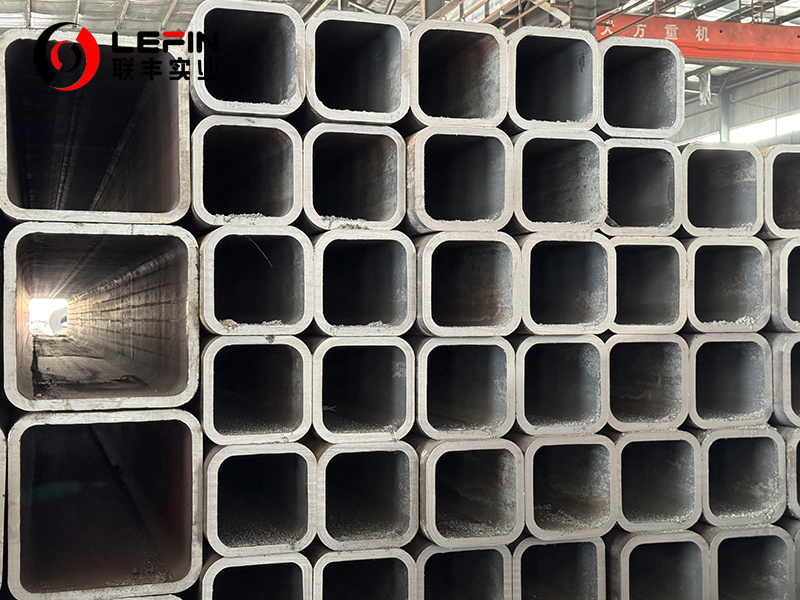

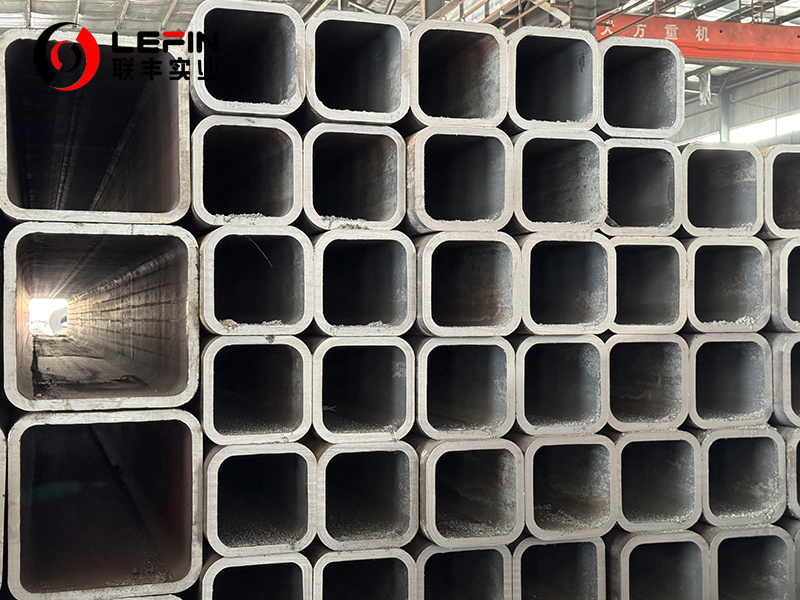

EN 10210 S355J2H Carbon Steel Pipe

Subcategory

Keyword

- Details

-

Standard And Material Specification

Standard: EN 10210

A European standard specifying the technical delivery conditions for hot-finished hollow structural sections (HSS) made of non-alloy and fine-grain steels.Grade: S355J2H

S355: Indicates minimum yield strength of 355 MPa at room temperature.J2: Charpy V-notch impact toughness requirement at -20°C (27 Joules minimum).

H: Denotes hot-finished production (as opposed to cold-formed).

Chemical PropertiesSteel Grade C Maximum Mn Maximum Si Maximum P Maximum S Maximum N Maximum S235JRH 0.17 1.40 – 0.040 0.040 0.009 S355J0H 0.22 1.60 0.55 0.035 0.035 0.009 S275J2H 0.20 1.50 – 0.030 0.030 – S355J2H 0.22 1.60 0.55 0.030 0.030 – S275J0H 0.20 1.50 – 0.035 0.035 0.009 S355K2H 0.22 1.60 0.55 0.030 0.030 – Carbon (C) – Enhances hardness and strength but reduces ductility and weldability (controlled to ≤0.22% for balance).

Silicon (Si) – Improves strength and deoxidation during steelmaking (limited to ≤0.55% to avoid brittleness).

Manganese (Mn) – Increases strength and hardenability while improving hot workability (≤1.6%).

Phosphorus (P) & Sulfur (S) – Harmful impurities (≤0.030% each); reduce toughness and promote cracking.

Key Impact: Elements are balanced to achieve optimal mechanical properties (strength, weldability, impact resistance) for structural applications.

Mechanical Properties

EN 10210

Mechanical Strength Impact Energy Yield Strength

(WT≤16mm)

Elongation (%)

(WT≤40mm)

Tensile Strength

(WT≤3mm)

Test Temperature in celsius -20 0 20 S355J2H 355 22 510-680 27 – – S275J0H 275 23 430-580 – 27 – S275J2H 275 23 430-580 27 – – S235JRH 235 26 360-510 – – 27 S355J0H 355 22 510-680 – 27 – S355K2H 355 22 510-680 40 – – Yield Strength (≥355 MPa) – Indicates the stress at which permanent deformation begins; ensures structural stability under load.

Tensile Strength (510–680 MPa) – Measures maximum stress before failure; guarantees resistance to breaking under tension.

Elongation (≥22%) – Reflects ductility; higher values mean better formability and crack resistance.

Charpy Impact (≥27 J at -20°C) – Evaluates toughness in cold environments; critical for shock/fracture resistance.

Key Impact: These properties ensure the pipe can withstand heavy loads, dynamic forces, and low temperatures without failure.

Manufacturing Process

Raw Material Preparation: High-quality steel slabs or billets with the specified chemical composition for S355J2H are selected.Heating: The steel is heated to around 1100–1200°C to make it ductile for shaping.

Rolling: The heated steel is rolled through specialized mills to form the rectangular hollow sections, ensuring precise dimensions and uniform wall thickness.

Cooling and Straightening: The pipe is cooled gradually to avoid internal stresses and then straightened if necessary.

Inspection and Testing: The finished pipe undergoes dimensional checks, non-destructive testing (e.g., ultrasonic), and mechanical property tests to ensure compliance with EN 10210 standards.

Surface Treatment (Optional): The pipe may be painted or galvanized to enhance corrosion resistance.

Packaging and Storage: The pipes are packaged and stored for shipment.

Applications

Structural Engineering: Building frames, bridges, and offshore platforms.Mechanical Components: Heavy machinery, load-bearing parts.

Infrastructure: Pipelines, support columns, and crane booms.

Advantages

High Strength-to-Weight Ratio: Suitable for heavy-load applications.Good Weldability: Preheating may be required for thick sections.

Impact Resistance: Reliable performance in low-temperature environments.

In summary, EN 10210 S355J2H is a high-strength carbon steel pipe offering excellent mechanical properties and impact resistance. Its hot-finished production ensures superior quality for structural applications in construction, machinery, and infrastructure. With certified performance and cost efficiency, it's a reliable choice for demanding engineering projects.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn