- Details

-

Detailed requirements of S235JRH (based on EN 10025-2)

Chemical composition (smelting analysis) :Carbon (C) : ≤ 0.17% (maximum)

Manganese (Mn) : ≤ 1.40% (maximum)

Phosphorus (P) : ≤ 0.035% (maximum)

Sulfur (S) : ≤ 0.035% (maximum) - But to meet the requirements of impact resistance and ductility, the actual content is usually controlled to be lower.

Silicon (Si) : ≤ 0.35% (usual)

Nitrogen (N) : 0.012% or less (maximum) - if the content of aluminum (Al) is high enough (e.g. 0.020% or higher).

Other elements also have limitations (such as the sum of Cu, Cr, Ni, Mo, V, etc.).

Objective: To ensure weldability, certain strength, toughness and processing performance (especially for forming pipes).

Mechanical properties (tested on the final product or representative samples) :

Yield strength (ReH/Rp0.2): ≥ 235 MPa (a typical requirement value when the steel plate thickness is ≤ 16mm. The yield strength will slightly decrease with the increase of thickness. The specific minimum values for different thicknesses are specified in the table in the standard.

Tensile strength (Rm): Generally within the range of 360-510 MPa (with specific ranges for different thicknesses).

Elongation after fracture (A5 / A50mm): Minimum value ≥ 21% (tested on specimens with gauge length L0=5.65√S0 in accordance with standard EN ISO 6892-1). This is an important indicator of the plasticity and ductility of the material, which is crucial for ensuring the cold/hot forming capacity of the pipe and the ductile failure mode (rather than brittle fracture) of the final structure.

Impact energy (KV) : Tested at +20°C, the average value of three standard samples is ≥ 27 J, and the minimum value of a single sample is ≥ 20 J.

Delivery status: Usually in hot-rolled condition (As Rolled - AR).

Weldability: S235JRH belongs to carbon-manganese structural steel (CMn steel) and has good weldability. Common arc welding methods (such as SMAW, MAG/MIG, SAW, etc.) can be adopted. When welding, the general welding specifications for structural steel must be followed. Preheating is usually not necessary, except under extreme thickness or constraint conditions.

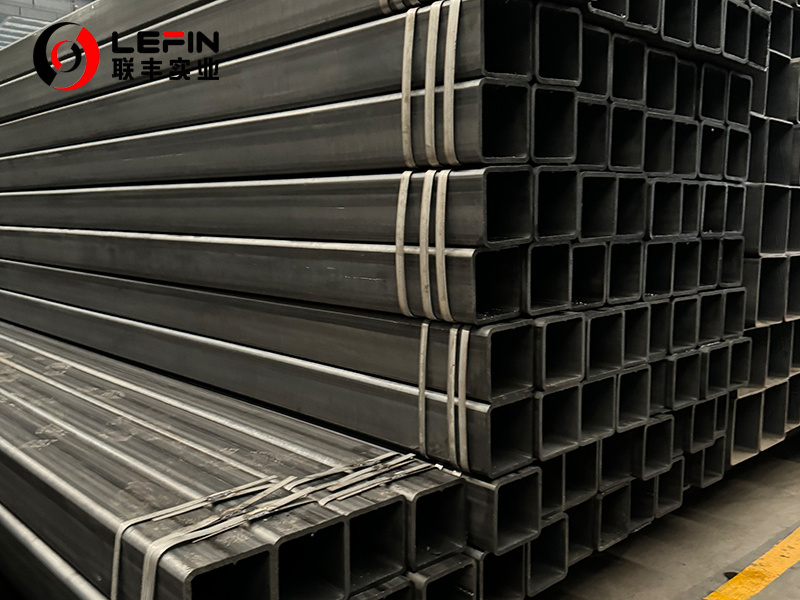

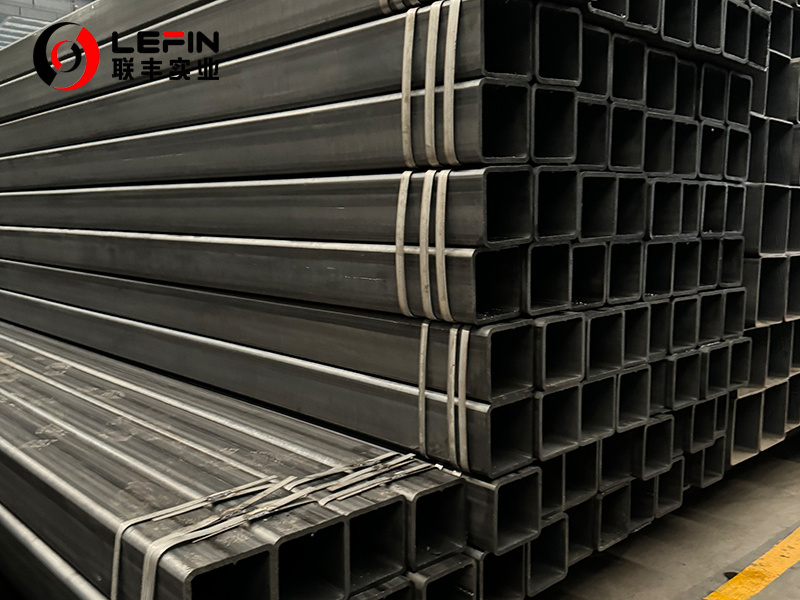

Product form: HOLLOW SECTION (Hollow steel)

What is it? Refers to hollow tubular structural profiles. It is widely applied in structural engineering, mainly including:

Square Hollow Sections (SHS)

Rectangular Hollow Sections (Rectangular Hollow sections - RHS)

Circular Hollow Sections - CHS/Pipes

Relevant standards: The standards describing the performance, dimensional tolerances, and geometric characteristics (SECTION modulus, moment of inertia, etc.) of the S235JRH HOLLOW SECTION are:

EN 10210-1:2006 + A1:2013: "Hot-formed hollow sections of non-alloy and fine-grained structural steels - Part 1: Technical conditions for delivery". This is the execution standard of the pipe itself. It stipulates requirements such as chemical, mechanical, dimensional tolerances and inspection.

EN 10210-2: 2006 + A1:2017: "Hot formed hollow sections of non-alloy and fine-grained structural steels - Part 2: Dimensions and cross-sectional characteristics". This part specifies the specific specifications (outer diameter/side length, wall thickness) and the corresponding cross-sectional geometric characteristic data.

Manufacturing process:

Steel of grade S235JRH (usually hot-rolled steel plates or strips conforming to EN 10025-2) is used as raw materials.

The final hollow section steel is made through "hot forming" processes (such as hot rolling, hot pushing and bending, hot expanding, hot extrusion, etc., but the most common one is to bend hot-rolled steel plates or strips at high temperatures and then weld them).

Key points: Hollow section steel made from S235JRH as raw material in compliance with EN 10210, the guaranteed yield strength value of the final product is usually ≥ 255 MPa (according to EN 10210-1), and the tensile strength is approximately 360-510 MPa (for specific details, refer to the standard). This improvement is brought about by the shaping effect. When designing, this 255 MPa should be used as the lower limit of yield strength for structural calculation (instead of 235 MPa of raw materials).

Advantage (using S235JRH HS):

High structural efficiency: The hollow closed section has excellent bending and torsional stiffness (with a large section modulus), while being relatively light in weight.

Beautiful and simple: The shape is clean and the lines are smooth, meeting the requirements of modern architectural aesthetics.

Convenient connection: The pipe ends are easy to seal or groove, facilitating connection with other components (pipes, plates, bolts).

Good compressive stability: The cross-section is isotropic or approximately isotropic, and the buckling performance around weak axes is better than that of open sections (such as I-beams).

Good cost performance: Among the structural steel grades, S235 is a relatively low-strength grade, and its cost is usually lower than that of higher-strength steels such as S275 and S355. In addition, the JR grade toughness requirement is not high (meeting the room temperature standard is sufficient), making it an ideal choice for cost-sensitive applications in normal temperature environments. The suffix "H" ensures the forming ability.

Typical applications:

Building structure: spatial frame, roof truss, truss, column, curtain wall support.

Mechanical equipment: frames, brackets, guide rails, structural components of conveying systems.

Bridges: Components of pedestrian overpasses and small highway Bridges.

Agricultural machinery: frame, casing.

Temporary structures: scaffolding (partial components), support systems.

Furniture: High-end or heavy furniture structures (such as display stands, workbenches).

Non-critical load-bearing components or secondary structures.

What is EN 10025 S235JRH HOLLOW SECTION?

It refers to the structural steel that meets the requirements of grade S235JRH in the European standard EN 10025-2 (replacing the old version EN 10025).S235 indicates that the minimum yield strength of its raw material (steel plate/strip steel) is 235 MPa.

JR indicates that it has a minimum average impact energy value of ≥ 27J at room temperature (+20°C).

The letter "H" is a key suffix, indicating that this steel is specifically designed for manufacturing hollow sections.

Through composition or process adjustments, it ensures that it has sufficient ductility and work hardening characteristics. It can meet the requirements of the subsequent pipe forming process and the performance requirements of the final hollow section steel product standard (EN 10210-1) (especially the elongation ≥21% and the yield strength of the final product ≥255 MPa).

HOLLOW SECTION refers to square tubes, rectangular tubes or round tubes whose final product form is thermoformed (mainly welded), and their specific properties, dimensions and characteristics are stipulated in EN 10210-1 and EN 10210-2. The guaranteed yield strength of the final pipe material is higher than that of the raw material (usually ≥ 255 MPa).

EN10025 S235JRH HOLLOW SECTION

Subcategory

Keyword

- Details

-

Detailed requirements of S235JRH (based on EN 10025-2)

Chemical composition (smelting analysis) :Carbon (C) : ≤ 0.17% (maximum)

Manganese (Mn) : ≤ 1.40% (maximum)

Phosphorus (P) : ≤ 0.035% (maximum)

Sulfur (S) : ≤ 0.035% (maximum) - But to meet the requirements of impact resistance and ductility, the actual content is usually controlled to be lower.

Silicon (Si) : ≤ 0.35% (usual)

Nitrogen (N) : 0.012% or less (maximum) - if the content of aluminum (Al) is high enough (e.g. 0.020% or higher).

Other elements also have limitations (such as the sum of Cu, Cr, Ni, Mo, V, etc.).

Objective: To ensure weldability, certain strength, toughness and processing performance (especially for forming pipes).

Mechanical properties (tested on the final product or representative samples) :

Yield strength (ReH/Rp0.2): ≥ 235 MPa (a typical requirement value when the steel plate thickness is ≤ 16mm. The yield strength will slightly decrease with the increase of thickness. The specific minimum values for different thicknesses are specified in the table in the standard.

Tensile strength (Rm): Generally within the range of 360-510 MPa (with specific ranges for different thicknesses).

Elongation after fracture (A5 / A50mm): Minimum value ≥ 21% (tested on specimens with gauge length L0=5.65√S0 in accordance with standard EN ISO 6892-1). This is an important indicator of the plasticity and ductility of the material, which is crucial for ensuring the cold/hot forming capacity of the pipe and the ductile failure mode (rather than brittle fracture) of the final structure.

Impact energy (KV) : Tested at +20°C, the average value of three standard samples is ≥ 27 J, and the minimum value of a single sample is ≥ 20 J.

Delivery status: Usually in hot-rolled condition (As Rolled - AR).

Weldability: S235JRH belongs to carbon-manganese structural steel (CMn steel) and has good weldability. Common arc welding methods (such as SMAW, MAG/MIG, SAW, etc.) can be adopted. When welding, the general welding specifications for structural steel must be followed. Preheating is usually not necessary, except under extreme thickness or constraint conditions.

Product form: HOLLOW SECTION (Hollow steel)

What is it? Refers to hollow tubular structural profiles. It is widely applied in structural engineering, mainly including:

Square Hollow Sections (SHS)

Rectangular Hollow Sections (Rectangular Hollow sections - RHS)

Circular Hollow Sections - CHS/Pipes

Relevant standards: The standards describing the performance, dimensional tolerances, and geometric characteristics (SECTION modulus, moment of inertia, etc.) of the S235JRH HOLLOW SECTION are:

EN 10210-1:2006 + A1:2013: "Hot-formed hollow sections of non-alloy and fine-grained structural steels - Part 1: Technical conditions for delivery". This is the execution standard of the pipe itself. It stipulates requirements such as chemical, mechanical, dimensional tolerances and inspection.

EN 10210-2: 2006 + A1:2017: "Hot formed hollow sections of non-alloy and fine-grained structural steels - Part 2: Dimensions and cross-sectional characteristics". This part specifies the specific specifications (outer diameter/side length, wall thickness) and the corresponding cross-sectional geometric characteristic data.

Manufacturing process:

Steel of grade S235JRH (usually hot-rolled steel plates or strips conforming to EN 10025-2) is used as raw materials.

The final hollow section steel is made through "hot forming" processes (such as hot rolling, hot pushing and bending, hot expanding, hot extrusion, etc., but the most common one is to bend hot-rolled steel plates or strips at high temperatures and then weld them).

Key points: Hollow section steel made from S235JRH as raw material in compliance with EN 10210, the guaranteed yield strength value of the final product is usually ≥ 255 MPa (according to EN 10210-1), and the tensile strength is approximately 360-510 MPa (for specific details, refer to the standard). This improvement is brought about by the shaping effect. When designing, this 255 MPa should be used as the lower limit of yield strength for structural calculation (instead of 235 MPa of raw materials).

Advantage (using S235JRH HS):

High structural efficiency: The hollow closed section has excellent bending and torsional stiffness (with a large section modulus), while being relatively light in weight.

Beautiful and simple: The shape is clean and the lines are smooth, meeting the requirements of modern architectural aesthetics.

Convenient connection: The pipe ends are easy to seal or groove, facilitating connection with other components (pipes, plates, bolts).

Good compressive stability: The cross-section is isotropic or approximately isotropic, and the buckling performance around weak axes is better than that of open sections (such as I-beams).

Good cost performance: Among the structural steel grades, S235 is a relatively low-strength grade, and its cost is usually lower than that of higher-strength steels such as S275 and S355. In addition, the JR grade toughness requirement is not high (meeting the room temperature standard is sufficient), making it an ideal choice for cost-sensitive applications in normal temperature environments. The suffix "H" ensures the forming ability.

Typical applications:

Building structure: spatial frame, roof truss, truss, column, curtain wall support.

Mechanical equipment: frames, brackets, guide rails, structural components of conveying systems.

Bridges: Components of pedestrian overpasses and small highway Bridges.

Agricultural machinery: frame, casing.

Temporary structures: scaffolding (partial components), support systems.

Furniture: High-end or heavy furniture structures (such as display stands, workbenches).

Non-critical load-bearing components or secondary structures.

What is EN 10025 S235JRH HOLLOW SECTION?

It refers to the structural steel that meets the requirements of grade S235JRH in the European standard EN 10025-2 (replacing the old version EN 10025).S235 indicates that the minimum yield strength of its raw material (steel plate/strip steel) is 235 MPa.

JR indicates that it has a minimum average impact energy value of ≥ 27J at room temperature (+20°C).

The letter "H" is a key suffix, indicating that this steel is specifically designed for manufacturing hollow sections.

Through composition or process adjustments, it ensures that it has sufficient ductility and work hardening characteristics. It can meet the requirements of the subsequent pipe forming process and the performance requirements of the final hollow section steel product standard (EN 10210-1) (especially the elongation ≥21% and the yield strength of the final product ≥255 MPa).

HOLLOW SECTION refers to square tubes, rectangular tubes or round tubes whose final product form is thermoformed (mainly welded), and their specific properties, dimensions and characteristics are stipulated in EN 10210-1 and EN 10210-2. The guaranteed yield strength of the final pipe material is higher than that of the raw material (usually ≥ 255 MPa).

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn