- Details

-

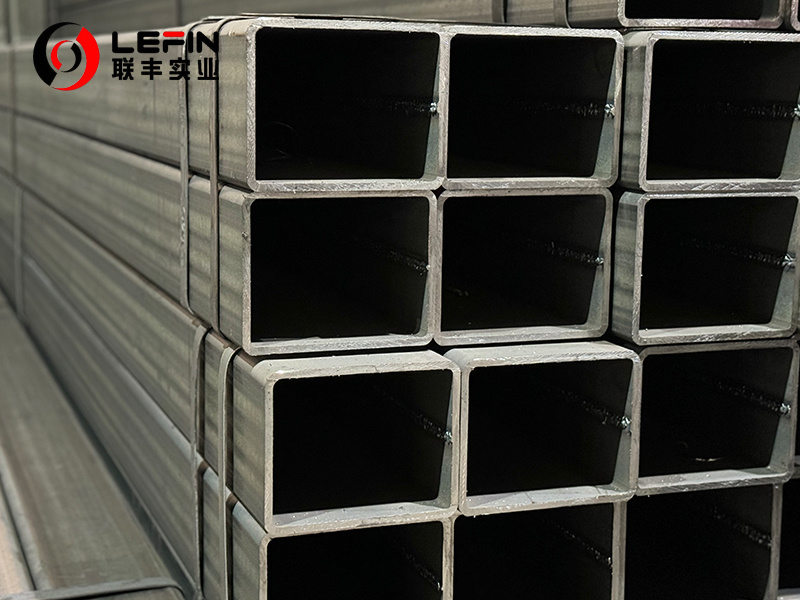

Standard & Scope

ASTM A500 is a standard specification issued by ASTM International for cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes. Grade C is one of the strength grades under this standard, with a minimum tensile strength of 425 MPa and a minimum yield strength of 315 MPa( in round structural tubing). primarily used in structural applications such as buildings, bridges, and machinery.● ASTM A500 GR.C Steel Structural Tubing in Rounds and Shapes

Standard: ASTM A500Grade: GR.C

Outside diameter:20-660MM Wall Thickness: 1.3-16MM

Outside diameter:20*20-1200*1200MM Wall Thickness: 1.3-50MM

Outside diameter:20*20-1500*1500MM Wall Thickness: 1.2-50MM

The Wall Thickness Tolerance: control within the standard limits

Length: normally 5.8m, 6m, 12m or as your required

Manufacturing Process: Seamless or Welded

Surface Treatment: Bare Finish, Painting, Oiling, Galvanization......

Chemical Composition

The chemical composition of ASTM A500 Grade C is strictly controlled to ensure its mechanical properties and performance. The key elements and their maximum allowable percentages are as follows:Carbon (C): ≤ 0.23% for heat analysis, ≤ 0.27% for product analysis.

Manganese (Mn): ≤ 1.35% for heat analysis, ≤ 1.40% for product analysis.

Phosphorus (P): ≤ 0.035% for heat analysis, ≤ 0.045% for product analysis.

Sulfur (S): ≤ 0.035% for heat analysis, ≤ 0.045% for product analysis.

Copper (Cu): ≥ 0.20% for heat analysis, ≥ 0.18% for product analysis.

Mechanical Properties

ASTM A500 Grade C has the highest mechanical properties among the three main grades of ASTM A500. Its mechanical properties are as follows:Tensile Strength: ≥ 425 MPa.

Yield Strength:

≥ 315 MPa( in round structural tubing).

≥ 345 MPa( in shaped structural tubing).

Elongation: ≥ 21% (at a gauge length of 50 mm).Manufacturing Process

● Cold Forming Welding: The steel plate is rolled and welded into a tube through the electric resistance welding (ERW) process. Strict non-destructive testing (NDT) technology is used to ensure that the weld quality meets the standard requirements.

● Seamless Process: The steel billet is processed into a tube through hot rolling or cold drawing technology. This process can produce high-precision and high-strength tubes.

Applications

ASTM A500 Grade C is used in a variety of structural applications where high strength and reliability are required. These include:● Structural frameworks (e.g., buildings, stadiums).

● Mechanical components (e.g., frames, supports).

● Infrastructure projects (e.g., bridges, signposts).

Comparison To Other Grades

Grade A: Lower strength (≥45 ksi tensile, ≥33 ksi yield).Grade B: Intermediate (≥58 ksi tensile, ≥42 ksi yield).

Grade D: Higher yield strength (≥36 ksi) but specific to rectangular/square shapes.

Key Advantages

High Strength-to-Weight Ratio: Lighter than solid steel sections while maintaining strength.

Cost-Effective: Efficient material usage reduces costs.

Weldability & Formability: Suitable for fabrication and on-site modifications.

Conclusion

ASTM A500 Grade C is a versatile, high-strength structural steel tubing suitable for demanding applications. Its balanced mechanical properties, weldability, and availability in multiple shapes make it a preferred choice in construction and engineering. Compliance with ASTM A500 ensures reliability and performance in structural frameworks.

ASTM A500 GR.C Steel Structural Tubing in Rounds And Shapes

Subcategory

Keyword

- Details

-

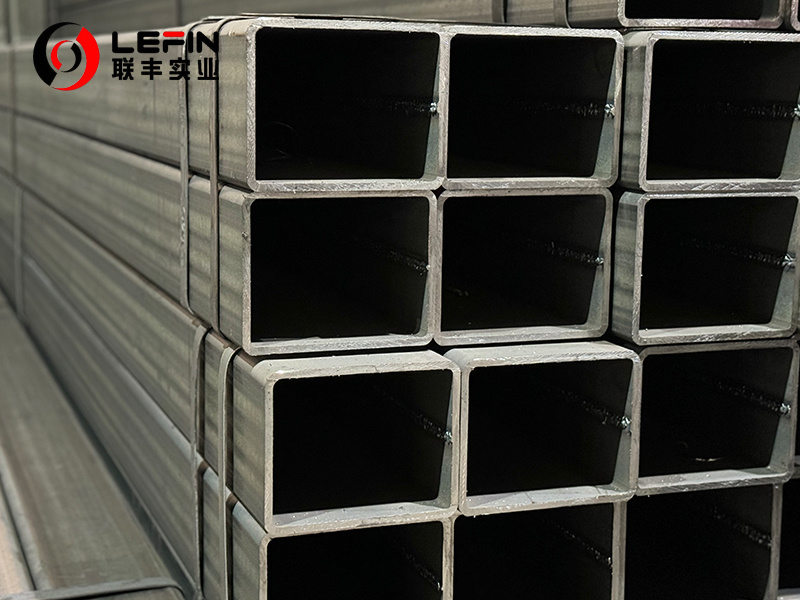

Standard & Scope

ASTM A500 is a standard specification issued by ASTM International for cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes. Grade C is one of the strength grades under this standard, with a minimum tensile strength of 425 MPa and a minimum yield strength of 315 MPa( in round structural tubing). primarily used in structural applications such as buildings, bridges, and machinery.● ASTM A500 GR.C Steel Structural Tubing in Rounds and Shapes

Standard: ASTM A500Grade: GR.C

Outside diameter:20-660MM Wall Thickness: 1.3-16MM

Outside diameter:20*20-1200*1200MM Wall Thickness: 1.3-50MM

Outside diameter:20*20-1500*1500MM Wall Thickness: 1.2-50MM

The Wall Thickness Tolerance: control within the standard limits

Length: normally 5.8m, 6m, 12m or as your required

Manufacturing Process: Seamless or Welded

Surface Treatment: Bare Finish, Painting, Oiling, Galvanization......

Chemical Composition

The chemical composition of ASTM A500 Grade C is strictly controlled to ensure its mechanical properties and performance. The key elements and their maximum allowable percentages are as follows:Carbon (C): ≤ 0.23% for heat analysis, ≤ 0.27% for product analysis.

Manganese (Mn): ≤ 1.35% for heat analysis, ≤ 1.40% for product analysis.

Phosphorus (P): ≤ 0.035% for heat analysis, ≤ 0.045% for product analysis.

Sulfur (S): ≤ 0.035% for heat analysis, ≤ 0.045% for product analysis.

Copper (Cu): ≥ 0.20% for heat analysis, ≥ 0.18% for product analysis.

Mechanical Properties

ASTM A500 Grade C has the highest mechanical properties among the three main grades of ASTM A500. Its mechanical properties are as follows:Tensile Strength: ≥ 425 MPa.

Yield Strength:

≥ 315 MPa( in round structural tubing).

≥ 345 MPa( in shaped structural tubing).

Elongation: ≥ 21% (at a gauge length of 50 mm).Manufacturing Process

● Cold Forming Welding: The steel plate is rolled and welded into a tube through the electric resistance welding (ERW) process. Strict non-destructive testing (NDT) technology is used to ensure that the weld quality meets the standard requirements.

● Seamless Process: The steel billet is processed into a tube through hot rolling or cold drawing technology. This process can produce high-precision and high-strength tubes.

Applications

ASTM A500 Grade C is used in a variety of structural applications where high strength and reliability are required. These include:● Structural frameworks (e.g., buildings, stadiums).

● Mechanical components (e.g., frames, supports).

● Infrastructure projects (e.g., bridges, signposts).

Comparison To Other Grades

Grade A: Lower strength (≥45 ksi tensile, ≥33 ksi yield).Grade B: Intermediate (≥58 ksi tensile, ≥42 ksi yield).

Grade D: Higher yield strength (≥36 ksi) but specific to rectangular/square shapes.

Key Advantages

High Strength-to-Weight Ratio: Lighter than solid steel sections while maintaining strength.

Cost-Effective: Efficient material usage reduces costs.

Weldability & Formability: Suitable for fabrication and on-site modifications.

Conclusion

ASTM A500 Grade C is a versatile, high-strength structural steel tubing suitable for demanding applications. Its balanced mechanical properties, weldability, and availability in multiple shapes make it a preferred choice in construction and engineering. Compliance with ASTM A500 ensures reliability and performance in structural frameworks.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn