- Details

-

Overview

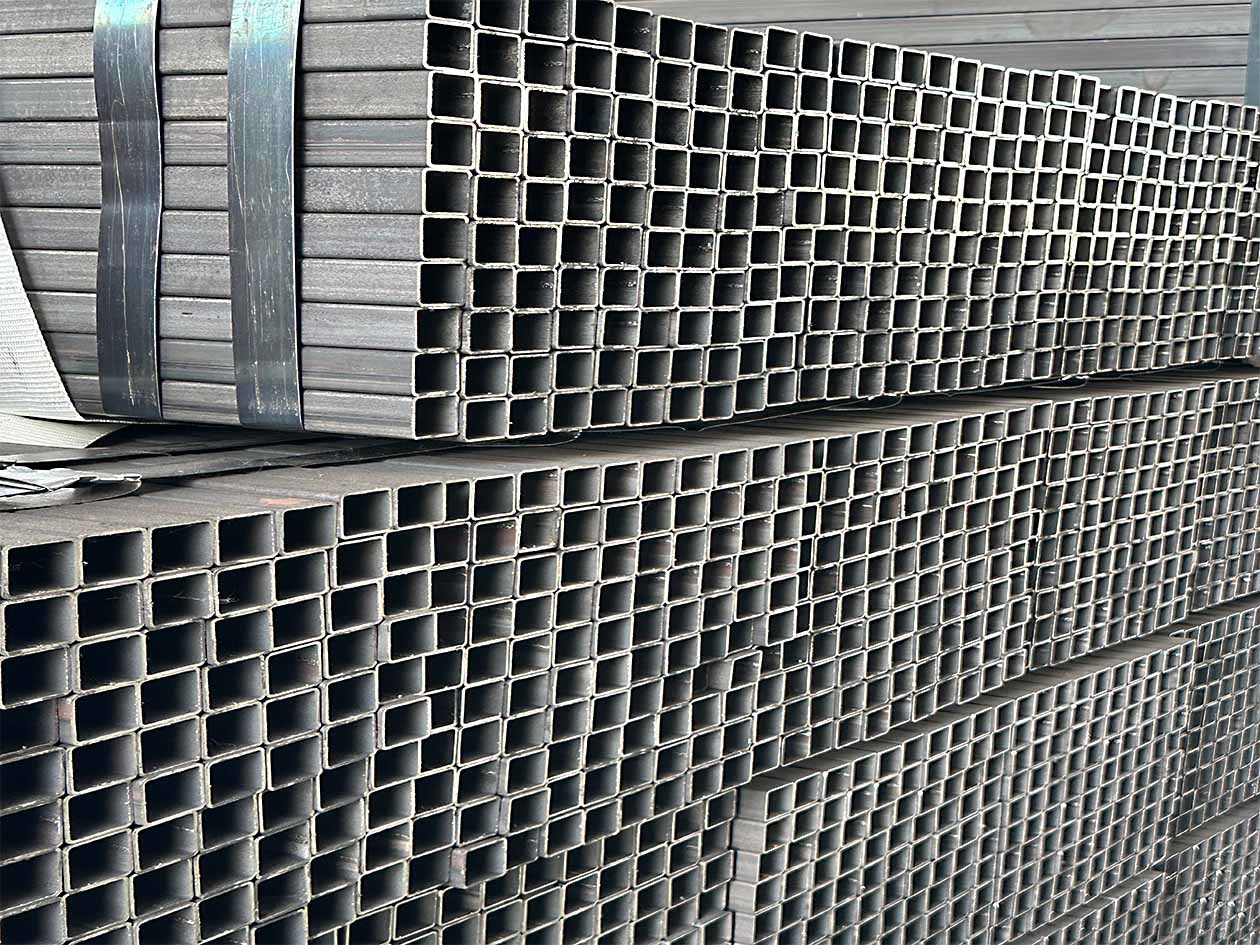

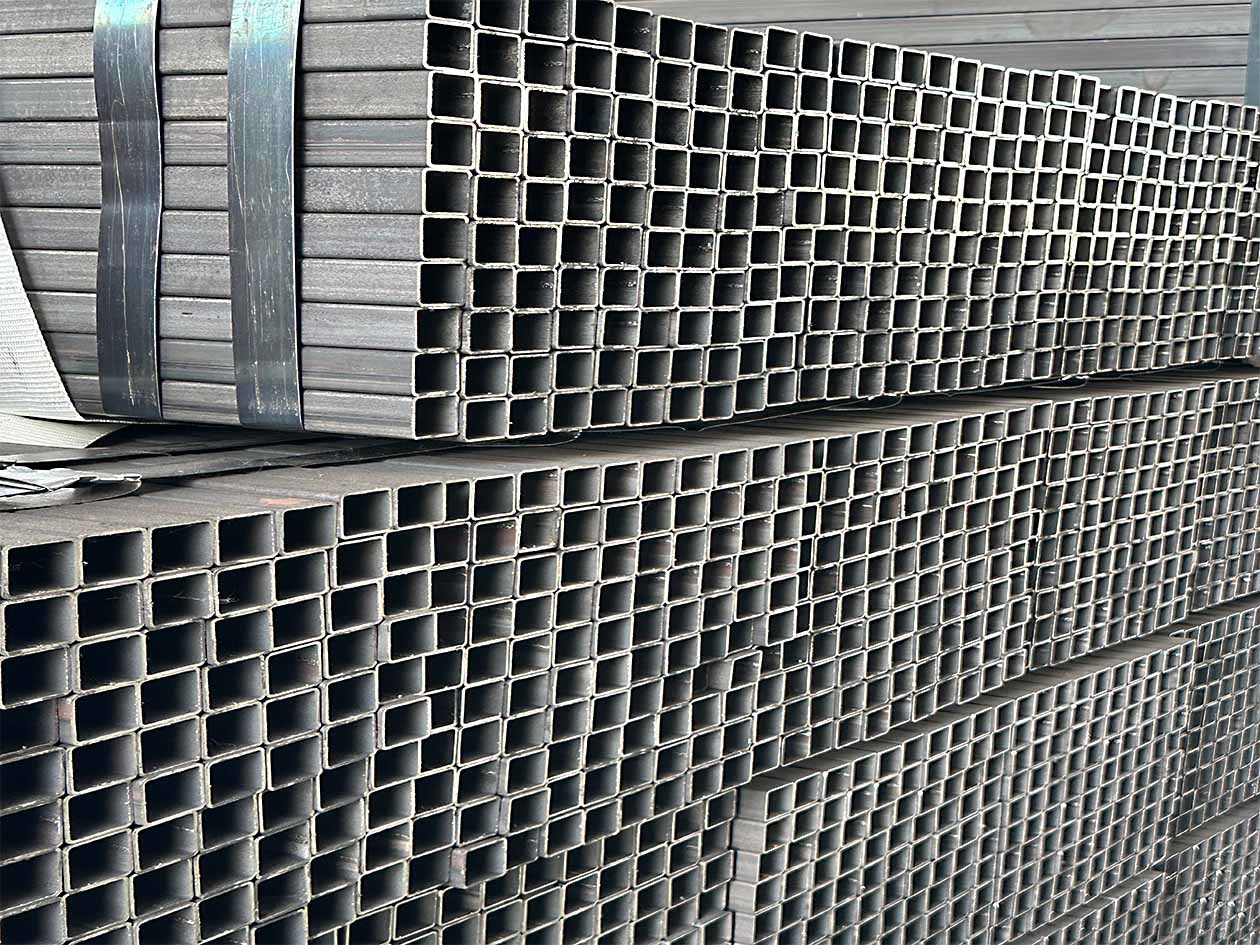

JIS G 3466 is a Japanese Industrial Standard that specifies the requirements for carbon steel tubes used primarily in machine structural applications. The standard covers seamless and welded tubes intended for mechanical and structural components in machinery, automobiles, and general engineering.● The STKR400 grade under this standard denotes a carbon steel tube with a minimum tensile strength of 400 MPa, making it suitable for medium-strength structural applications.

● JIS G3466 STKR400 Carbon Steel Tubes

Specification:

OD: 20MM × 20MM - 1200MM × 1200MM (SHS); 20MM × 30MM - 1200MM × 1500MM (RHS)

WT: 1.3MM - 50MM

Length: Commonly used 5.8M,6M,12M,or as your requirement

Surface Treatments: Coating, Hot-dip galvanized, Painting

Application: General machinery parts, Automotive components, Construction equipment, Industrial machinery

Chemical Composition And Mechanical Properties

Chemical Composition (STKR400)

The chemical composition of STKR400 must comply with the following requirements (typical values):Element

Composition (%) (Max)

Carbon (C) ≤ 0.25 Silicon (Si) - Manganese (Mn) - Phosphorus (P) ≤ 0.040 Sulfur (S) ≤ 0.040 (Note: Exact limits may vary slightly depending on manufacturing processes.)

Mechanical Properties (STKR400)Property

Requirement

Tensile Strength (MPa) ≥ 400 Yield Strength (MPa) ≥ 245 Elongation (%) ≥ 23 (based on specimen dimensions) These properties ensure good formability, weldability, and structural integrity for mechanical applications.

Manufacturing Process

Seamless Tubes: Produced by hot-rolling or cold-drawing without welding.Welded Tubes: Made by electric resistance welding (ERW) or other welding methods, followed by heat treatment if required.

Applications And Advantages

Applications

STKR400 tubes are commonly used in:● Automotive parts (chassis, frames)

● Construction machinery (booms, arms)

● General mechanical structures (supports, brackets)

● Industrial equipment (conveyors, hydraulic systems)

Advantages

● High Strength: Capable of withstanding high loads and providing structural stability.

● Excellent Weldability: The low carbon content ensures good weldability, making it easy to join with other steel components.

● Cost-Effective: Offers a balance of strength and cost, making it suitable for a wide range of applications.

Comparison With Other GradesGrade

Tensile Strength (MPa)

Yield Strength (MPa)

Key Features

STKR400 ≥ 400 ≥ 245 Balanced strength & formability STKR490 ≥ 490 ≥ 325 Higher strength, less ductile

Testing & Inspection

Tubes must undergo:● Tensile testing

● Flattening test / Flaring test (for ductility)

● Hydrostatic or non-destructive testing (NDT) for leaks/defects

Conclusion

JIS G 3466 STKR400 is a medium-strength carbon steel tube suitable for structural and mechanical applications requiring good weldability and formability. It is widely used in Japan and internationally for automotive and industrial components.

JIS G3466 STKR400 Carbon Steel Tubes

Subcategory

Keyword

- Details

-

Overview

JIS G 3466 is a Japanese Industrial Standard that specifies the requirements for carbon steel tubes used primarily in machine structural applications. The standard covers seamless and welded tubes intended for mechanical and structural components in machinery, automobiles, and general engineering.● The STKR400 grade under this standard denotes a carbon steel tube with a minimum tensile strength of 400 MPa, making it suitable for medium-strength structural applications.

● JIS G3466 STKR400 Carbon Steel Tubes

Specification:

OD: 20MM × 20MM - 1200MM × 1200MM (SHS); 20MM × 30MM - 1200MM × 1500MM (RHS)

WT: 1.3MM - 50MM

Length: Commonly used 5.8M,6M,12M,or as your requirement

Surface Treatments: Coating, Hot-dip galvanized, Painting

Application: General machinery parts, Automotive components, Construction equipment, Industrial machinery

Chemical Composition And Mechanical Properties

Chemical Composition (STKR400)

The chemical composition of STKR400 must comply with the following requirements (typical values):Element

Composition (%) (Max)

Carbon (C) ≤ 0.25 Silicon (Si) - Manganese (Mn) - Phosphorus (P) ≤ 0.040 Sulfur (S) ≤ 0.040 (Note: Exact limits may vary slightly depending on manufacturing processes.)

Mechanical Properties (STKR400)Property

Requirement

Tensile Strength (MPa) ≥ 400 Yield Strength (MPa) ≥ 245 Elongation (%) ≥ 23 (based on specimen dimensions) These properties ensure good formability, weldability, and structural integrity for mechanical applications.

Manufacturing Process

Seamless Tubes: Produced by hot-rolling or cold-drawing without welding.Welded Tubes: Made by electric resistance welding (ERW) or other welding methods, followed by heat treatment if required.

Applications And Advantages

Applications

STKR400 tubes are commonly used in:● Automotive parts (chassis, frames)

● Construction machinery (booms, arms)

● General mechanical structures (supports, brackets)

● Industrial equipment (conveyors, hydraulic systems)

Advantages

● High Strength: Capable of withstanding high loads and providing structural stability.

● Excellent Weldability: The low carbon content ensures good weldability, making it easy to join with other steel components.

● Cost-Effective: Offers a balance of strength and cost, making it suitable for a wide range of applications.

Comparison With Other GradesGrade

Tensile Strength (MPa)

Yield Strength (MPa)

Key Features

STKR400 ≥ 400 ≥ 245 Balanced strength & formability STKR490 ≥ 490 ≥ 325 Higher strength, less ductile

Testing & Inspection

Tubes must undergo:● Tensile testing

● Flattening test / Flaring test (for ductility)

● Hydrostatic or non-destructive testing (NDT) for leaks/defects

Conclusion

JIS G 3466 STKR400 is a medium-strength carbon steel tube suitable for structural and mechanical applications requiring good weldability and formability. It is widely used in Japan and internationally for automotive and industrial components.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn