- Details

-

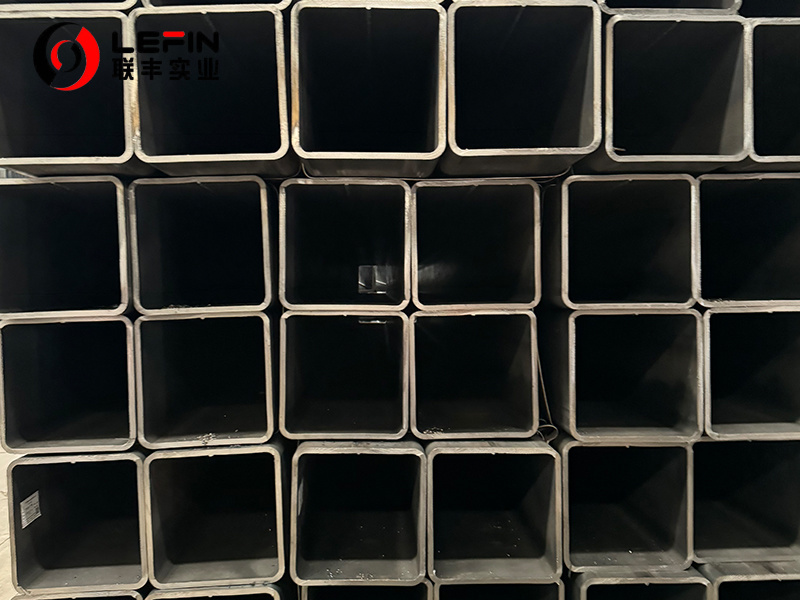

Standard Overview

JIS G 3466 is a Japanese Industrial Standard (JIS) that specifies carbon steel tubes for general structural purposes, such as buildings, bridges, towers, and machinery frames. The standard covers both welded and seamless steel tubes, with different grades classified by their minimum tensile strength.STKR490 is one of the key grades under JIS G 3466, designed for high-strength structural applications where good weldability and formability are required.

Material Designation (STKR490)

STKR490 = Grade designation (STKR = Steel Tube, Structure, Resistance-welded; 490 = Min. tensile strength in MPa)Key Features:

✔ High Strength: Suitable for load-bearing structures.

✔ Good Weldability: Optimized for welding without pre/post-heat treatment in most cases.

✔ Formability: Can be bent or shaped for structural frameworks.

Chemical Composition

The chemical composition of JIS G 3466 STKR490 ensures weldability and mechanical properties:Element

Content (Max, %)

Notes

Carbon (C)

≤0.18

Low carbon improves weldability.

Silicon (Si)

≤0.55

Enhances strength but kept moderate for welding.

Manganese (Mn)

≤1.65

Increases strength and hardenability.

Phosphorus (P)

≤0.035

Controlled to avoid brittleness.

Sulfur (S)

≤0.035

Minimized to prevent hot cracking.

● Exact composition may vary slightly depending on the manufacturer.

Mechanical PropertiesProperty

Requirement (STKR490)

Tensile Strength (MPa)

≥ 490

Yield Strength (MPa)

≥ 325 (typical)

Elongation (%)

≥ 23 (based on dimensions between 7mm and 8mm)

Impact Toughness

Not explicitly specified (depends on application requirements).

● Key Points:

High Tensile Strength: Suitable for heavy-duty structural applications.Moderate Yield Strength: Balances strength and ductility.

Good Elongation: Ensures some deformation capacity before fracture.

Manufacturing Process

STKR490 square and rectangular tubes are manufactured through several methods:● Forming Processes:

Electric resistance welding (ERW)

Forge welding

Automatic arc welding

Seamless steel pipes shaped into square forms

Forming steel strips into square or paired channel cross-sections, followed by continuous electric resistance welding or automatic arc welding

● Heat Treatment: Generally, STKR490 tubes are furnished in the as-manufactured condition and are not typically heat-treated.

● Galvanization: Upon customer request, STKR490 tubes can be made from galvanized steel sheets or strips.

Testing And Inspection

The testing and inspection of STKR490 tubes are conducted in accordance with the following standards:● Tensile Testing: Performed as per JIS Z 2241

● General Inspection Matters: Follow JIS G 0404

These tests ensure that the tubes meet the required mechanical properties and quality standards.

Applications

Due to its high strength and weldability, STKR490 is widely used in:● Building & Construction: Frames, columns, trusses.

● Bridge Components: Support structures, girders.

● Industrial Machinery: Heavy equipment frames, conveyor systems.

● Transportation: Truck chassis, trailer parts.

Conclusion

JIS G 3466 STKR490 is a high-strength carbon steel tube optimized for structural applications requiring good weldability and formability. It is widely used in construction, industrial machinery, and transportation due to its balance of strength and workability.For projects requiring higher strength than STKR400 but without specialized alloying, STKR490 is an excellent choice.

JIS G3466 STKR490 Carbon Steel Tubes

Subcategory

Keyword

- Details

-

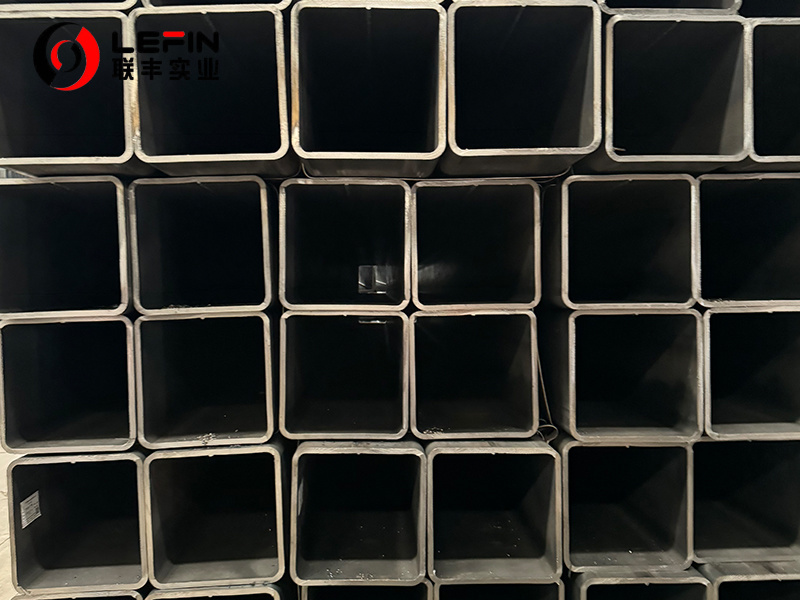

Standard Overview

JIS G 3466 is a Japanese Industrial Standard (JIS) that specifies carbon steel tubes for general structural purposes, such as buildings, bridges, towers, and machinery frames. The standard covers both welded and seamless steel tubes, with different grades classified by their minimum tensile strength.STKR490 is one of the key grades under JIS G 3466, designed for high-strength structural applications where good weldability and formability are required.

Material Designation (STKR490)

STKR490 = Grade designation (STKR = Steel Tube, Structure, Resistance-welded; 490 = Min. tensile strength in MPa)Key Features:

✔ High Strength: Suitable for load-bearing structures.

✔ Good Weldability: Optimized for welding without pre/post-heat treatment in most cases.

✔ Formability: Can be bent or shaped for structural frameworks.

Chemical Composition

The chemical composition of JIS G 3466 STKR490 ensures weldability and mechanical properties:Element

Content (Max, %)

Notes

Carbon (C)

≤0.18

Low carbon improves weldability.

Silicon (Si)

≤0.55

Enhances strength but kept moderate for welding.

Manganese (Mn)

≤1.65

Increases strength and hardenability.

Phosphorus (P)

≤0.035

Controlled to avoid brittleness.

Sulfur (S)

≤0.035

Minimized to prevent hot cracking.

● Exact composition may vary slightly depending on the manufacturer.

Mechanical PropertiesProperty

Requirement (STKR490)

Tensile Strength (MPa)

≥ 490

Yield Strength (MPa)

≥ 325 (typical)

Elongation (%)

≥ 23 (based on dimensions between 7mm and 8mm)

Impact Toughness

Not explicitly specified (depends on application requirements).

● Key Points:

High Tensile Strength: Suitable for heavy-duty structural applications.Moderate Yield Strength: Balances strength and ductility.

Good Elongation: Ensures some deformation capacity before fracture.

Manufacturing Process

STKR490 square and rectangular tubes are manufactured through several methods:● Forming Processes:

Electric resistance welding (ERW)

Forge welding

Automatic arc welding

Seamless steel pipes shaped into square forms

Forming steel strips into square or paired channel cross-sections, followed by continuous electric resistance welding or automatic arc welding

● Heat Treatment: Generally, STKR490 tubes are furnished in the as-manufactured condition and are not typically heat-treated.

● Galvanization: Upon customer request, STKR490 tubes can be made from galvanized steel sheets or strips.

Testing And Inspection

The testing and inspection of STKR490 tubes are conducted in accordance with the following standards:● Tensile Testing: Performed as per JIS Z 2241

● General Inspection Matters: Follow JIS G 0404

These tests ensure that the tubes meet the required mechanical properties and quality standards.

Applications

Due to its high strength and weldability, STKR490 is widely used in:● Building & Construction: Frames, columns, trusses.

● Bridge Components: Support structures, girders.

● Industrial Machinery: Heavy equipment frames, conveyor systems.

● Transportation: Truck chassis, trailer parts.

Conclusion

JIS G 3466 STKR490 is a high-strength carbon steel tube optimized for structural applications requiring good weldability and formability. It is widely used in construction, industrial machinery, and transportation due to its balance of strength and workability.For projects requiring higher strength than STKR400 but without specialized alloying, STKR490 is an excellent choice.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn