- Details

-

Overview

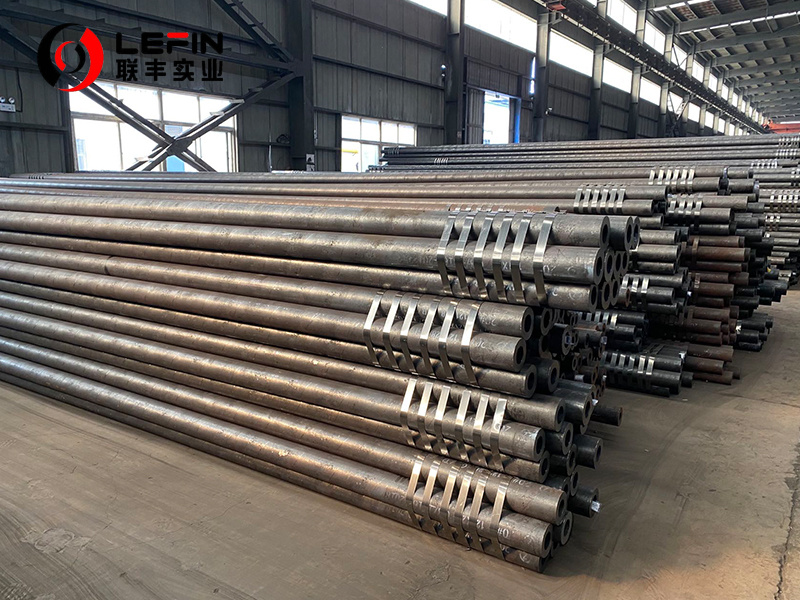

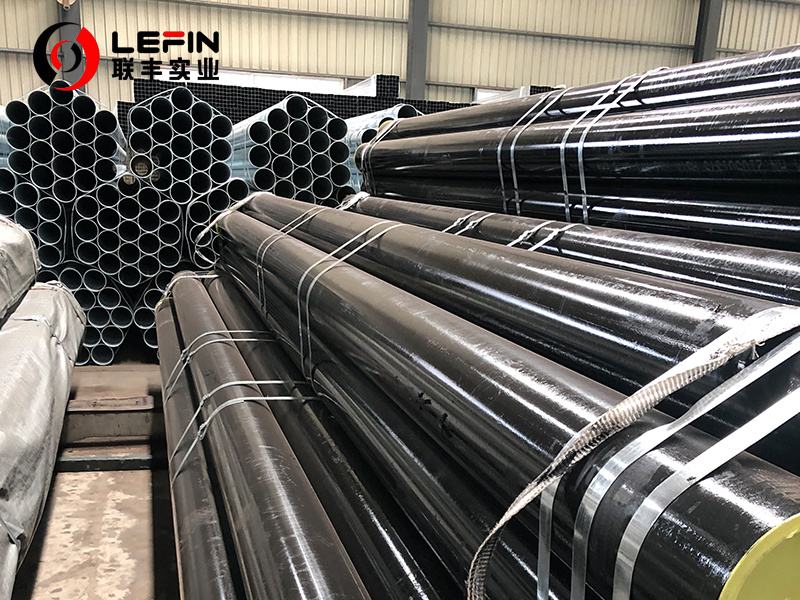

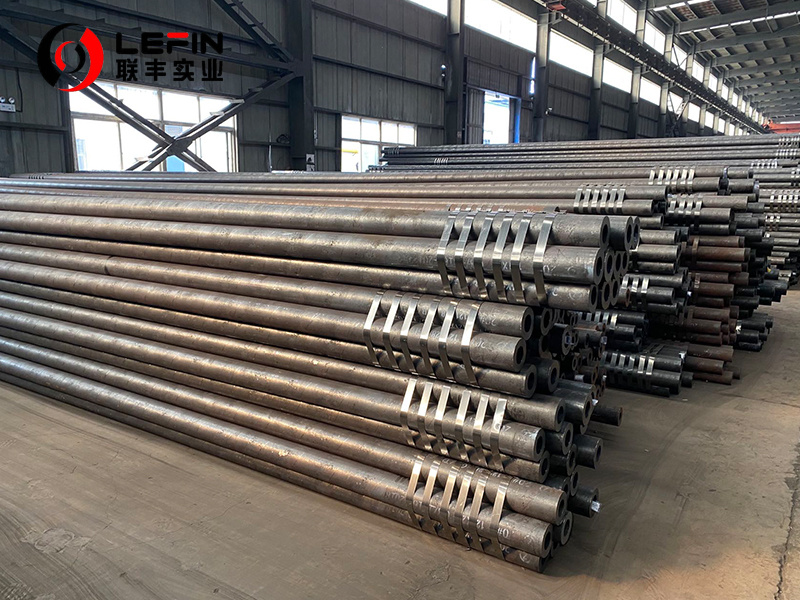

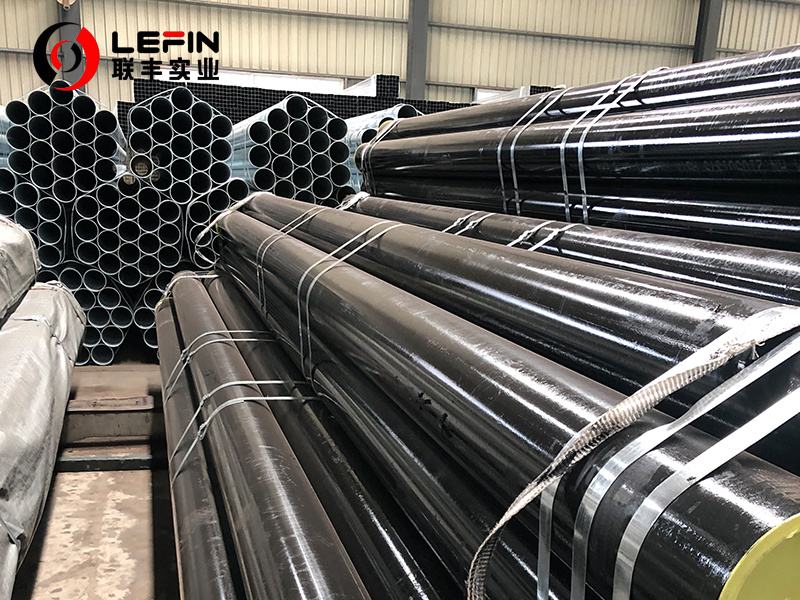

API 5L Line Pipe is a specification established by the American Petroleum Institute (API) that covers seamless and welded steel pipes used for transporting gas, water, and oil in the petroleum and natural gas industries. These pipes are designed for pipeline transportation systems and must meet strict mechanical, chemical, and dimensional requirements.

Grades And Types

API 5L pipes are classified into two product specification levels:PSL1 (Product Specification Level 1): Standard requirements for common pipeline use.

PSL2 (Product Specification Level 2): Enhanced requirements for higher strength, toughness, and stricter testing (e.g., for sour service or low-temperature environments).

Common Grades:

A25, A, B (Basic grades for low-pressure applications)

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120 (High-strength grades for demanding conditions)

Types Of Pipes:

Seamless Pipe (SMLS): No weld seam, ideal for high-pressure applications.

Welded Pipe (ERW, SAW, LSAW, DSAW):

Electric Resistance Welded (ERW): Cost-effective for moderate pressures.

Submerged Arc Welded (SAW): Longitudinal (LSAW) or spiral (HSAW) for large diameters.

Key Features And Requirements

● Material: Carbon or low-alloy steel with controlled chemical composition.● Dimensional Standards: Complies with specified outer diameter (OD), wall thickness (WT), and length.

● Mechanical Properties: Tensile strength, yield strength, and elongation per grade.

● Testing: Hydrostatic testing, nondestructive testing (NDT), Charpy impact test (for PSL2), and hardness testing.

● End Finishes: Beveled, plain, or threaded ends based on application needs.

Applications

● Oil And Gas Transmission: Onshore/offshore pipelines.● Water Supply And Distribution: Large-diameter pipes for municipal systems.

● Structural Uses: Piling, scaffolding (if compliant with additional standards).

Advantages

High durability and resistance to corrosion (with coatings like FBE or 3LPE).

Customizable for extreme environments (e.g., Arctic or deep-sea pipelines).

Globally recognized quality assurance.

Conclusion

In summary, API 5L line pipe is a crucial component in the oil and gas industry, designed to meet the demanding requirements of fluid transportation. Its high - quality standards, excellent mechanical properties, and reliable performance make it an essential part of the infrastructure for the global oil and gas supply chain.

Line Pipe:API 5L

Subcategory

Keyword

- Details

-

Overview

API 5L Line Pipe is a specification established by the American Petroleum Institute (API) that covers seamless and welded steel pipes used for transporting gas, water, and oil in the petroleum and natural gas industries. These pipes are designed for pipeline transportation systems and must meet strict mechanical, chemical, and dimensional requirements.

Grades And Types

API 5L pipes are classified into two product specification levels:PSL1 (Product Specification Level 1): Standard requirements for common pipeline use.

PSL2 (Product Specification Level 2): Enhanced requirements for higher strength, toughness, and stricter testing (e.g., for sour service or low-temperature environments).

Common Grades:

A25, A, B (Basic grades for low-pressure applications)

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120 (High-strength grades for demanding conditions)

Types Of Pipes:

Seamless Pipe (SMLS): No weld seam, ideal for high-pressure applications.

Welded Pipe (ERW, SAW, LSAW, DSAW):

Electric Resistance Welded (ERW): Cost-effective for moderate pressures.

Submerged Arc Welded (SAW): Longitudinal (LSAW) or spiral (HSAW) for large diameters.

Key Features And Requirements

● Material: Carbon or low-alloy steel with controlled chemical composition.● Dimensional Standards: Complies with specified outer diameter (OD), wall thickness (WT), and length.

● Mechanical Properties: Tensile strength, yield strength, and elongation per grade.

● Testing: Hydrostatic testing, nondestructive testing (NDT), Charpy impact test (for PSL2), and hardness testing.

● End Finishes: Beveled, plain, or threaded ends based on application needs.

Applications

● Oil And Gas Transmission: Onshore/offshore pipelines.● Water Supply And Distribution: Large-diameter pipes for municipal systems.

● Structural Uses: Piling, scaffolding (if compliant with additional standards).

Advantages

High durability and resistance to corrosion (with coatings like FBE or 3LPE).

Customizable for extreme environments (e.g., Arctic or deep-sea pipelines).

Globally recognized quality assurance.

Conclusion

In summary, API 5L line pipe is a crucial component in the oil and gas industry, designed to meet the demanding requirements of fluid transportation. Its high - quality standards, excellent mechanical properties, and reliable performance make it an essential part of the infrastructure for the global oil and gas supply chain.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn