- Details

-

Pipe elbows are essential pipe fittings used to change the direction of flow in a piping system. They are commonly used in plumbing, HVAC, industrial pipelines, and other fluid transport systems to navigate around obstacles or follow specific layout requirements. Elbows are available in various angles, with 45°, 90°, and 180° being the most common configurations.

Key Features Of Pipe Elbows

Material:

Typically made from metals (stainless steel, carbon steel, copper, brass) or plastics (PVC, CPVC, HDPE).Connection Types:

Threaded (Screwed) – Used for small-diameter pipes.

Socket Weld – Provides a strong, leak-proof joint.

Butt Weld – Common in high-pressure systems.

Flanged – Used for easy assembly and disassembly.

Radius Types:

Short Radius (SR) – Compact, used in tight spaces.

Long Radius (LR) – Smoother flow, less pressure drop.

Common Angle Classifications

One:45-Degree Elbow

A 45-degree elbow is a type of pipe fitting designed to change the direction of fluid flow in a piping system by 45 degrees. This fitting is essential for creating a smoother transition in the pipeline, minimizing turbulence and pressure loss compared to sharper bends like the 90-degree elbow.

Types Of 45-Degree Elbows

● Long Radius (LR) 45-Degree Elbow: The radius of this elbow is 1.5 times the diameter of the pipe. It provides a gentler bend, which helps to reduce friction and maintain a steady flow, making it ideal for high-pressure and high-flow applications.

● Short Radius (SR) 45-Degree Elbow: The radius is equal to the diameter of the pipe. This type is suitable for tight spaces and low-pressure applications but may increase turbulence and pressure drop due to the sharper bend.

Specifications

Key specifications for 45-degree elbows include:● Sizes: Typically range from 1/2" to 48".

● Pressure Ratings: Generally up to 9000 psi, depending on the material.

● Materials: Commonly made from carbon steel, stainless steel, and alloy steel.

● Wall Thickness: Available in various schedules, including SCH 10, SCH 40, and SCH 80.

These specifications make 45-degree elbows a versatile choice for efficient fluid redirection in diverse piping systemsApplications

45-degree elbows are widely used in various industries, including:● HVAC Systems: They help maintain consistent airflow with minimal resistance, enhancing energy efficiency.

● Water Supply Lines: These fittings support gentle redirection of water flow, crucial for maintaining steady pressure.

● Chemical Processing: In chemical plants, 45-degree elbows ensure stable flow of sensitive materials, preventing blockages and maintaining system integrity.

● Oil and Gas: They facilitate fluid movement in complex pipeline networks, ensuring efficient transport of crude oil and natural gas.

● Food and Beverage: Used in sanitary applications to direct food-grade liquids while maintaining hygiene standards.

Two:90-Degree Elbow

A 90-degree elbow, also known as a 90-degree bend or simply an elbow, is a critical pipe fitting used in piping systems to change the direction of fluid flow by 90 degrees. Here's a detailed introduction to 90-degree elbows:

Types Of 90-Degree Elbows

● Standard 90-Degree Elbow: This is the most common type, providing a sharp 90-degree turn in the pipe. It is available in both long radius and short radius versions, with the long radius being more forgiving in terms of flow characteristics.

● Long Radius 90-Degree Elbow: This elbow has a centerline radius that is approximately 1.5 times the pipe diameter. It is preferred in applications where minimizing pressure drop and flow disturbance is crucial.

● Short Radius 90-Degree Elbow: With a centerline radius equal to the pipe diameter, these elbows are more compact but can cause higher turbulence and pressure drop due to the sharper turn.

● Offset 90-Degree Elbow: Also known as an eccentric reducer elbow, it combines the function of a 90-degree turn with a size reduction, useful for space-limited applications.

● Swept 90-Degree Elbow: This type has a more gradual curve, which helps in reducing stress concentration and vibration in the piping system.

Specifications

● Sizes: Available in a wide range of sizes from 1/2" to 72" and larger, depending on the application.

● Materials: Can be made from various materials such as carbon steel, stainless steel, brass, bronze, copper, and plastic, depending on the corrosiveness of the fluid and the temperature and pressure conditions.

● Standards: Manufactured to meet international standards such as ASME/ANSI B16.9, B16.28, BS 3799, and DIN 2605.

● Pressure Ratings: Vary based on the material and the pipe schedule, with ratings from 150 psi to 2500 psi or higher for some materials.

● End Connections: Can be threaded, socket-weld, butt-weld, or flanged, depending on the system requirements and the type of fluid being handled.

Applications

90-degree elbows are used in a wide range of applications due to their ability to make sharp turns in piping systems:● Plumbing: In residential and commercial buildings for water supply, drainage, and gas lines.

● HVAC Systems: For directing air flow in heating, ventilation, and air conditioning systems.

● Industrial Processes: In chemical, petrochemical, and pharmaceutical industries for fluid transfer and process control.

● Power Generation: Used in steam and cooling water systems in power plants.

● Marine: For fuel, water, and waste management systems on ships and offshore platforms.

90-degree elbows are essential for creating right-angle turns in piping systems, and their selection should be based on the specific needs of the application, including the type of fluid, pressure, temperature, and space constraints.

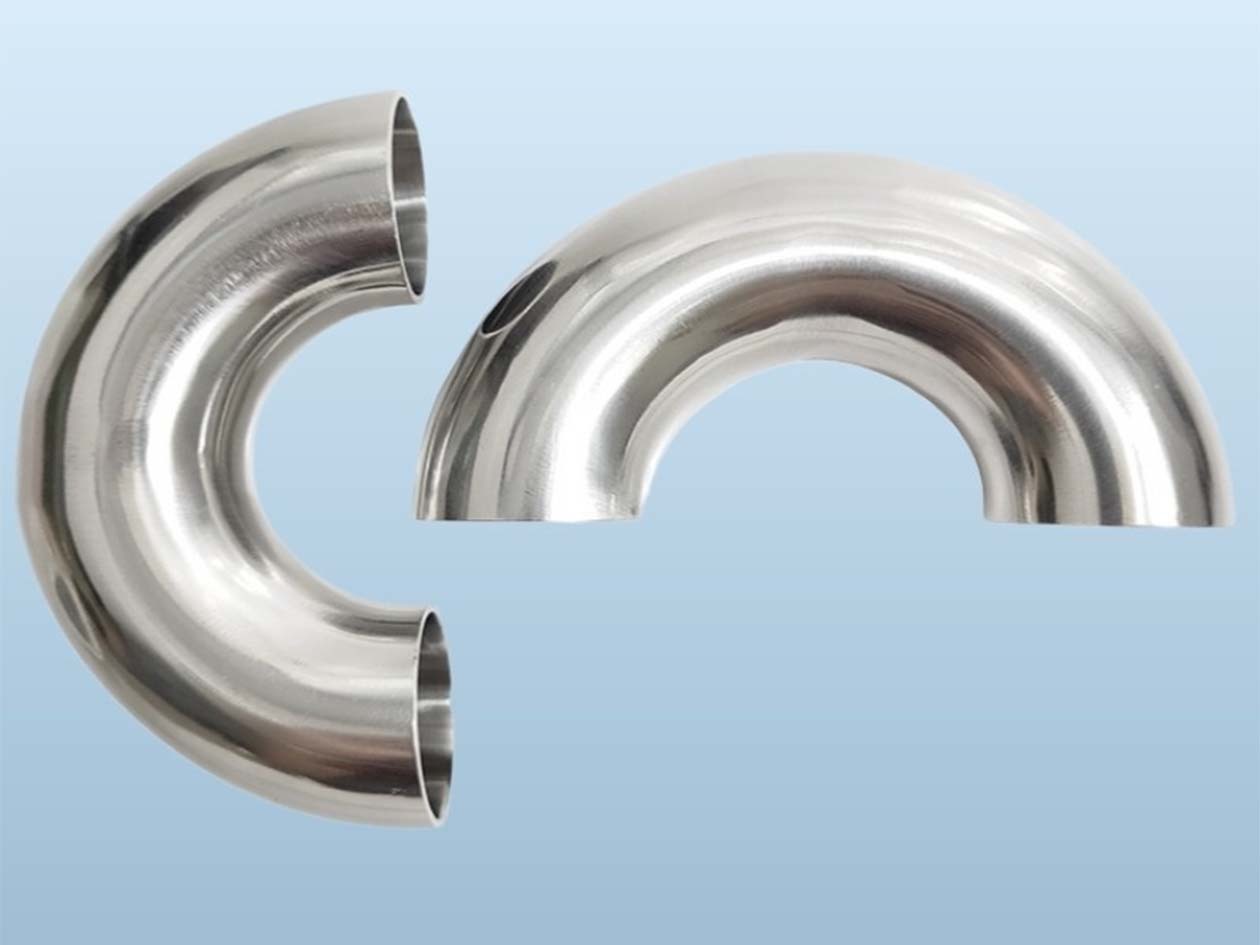

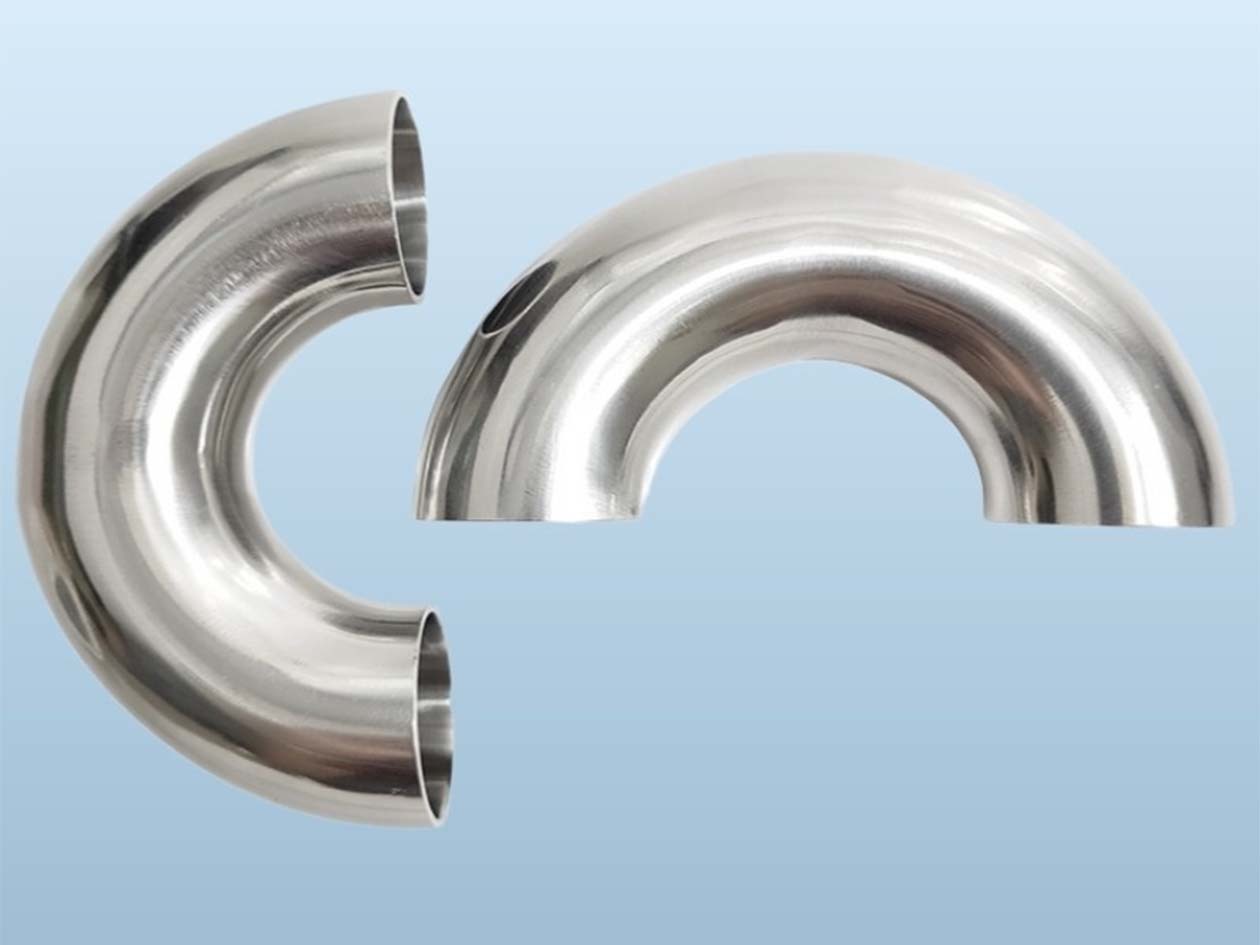

Three:180-Degree Elbow

A 180-degree elbow, also known as a "return bend" or "hairpin bend," is a type of pipe fitting used to reverse the direction of fluid flow in a piping system by a full 180 degrees.They are especially useful in applications where space is limited and a compact design is necessary, such as in wastewater treatment plants, chemical plants, and power generation facilities where pipelines need to make a sharp turn.

Types Of 180-Degree Elbows

There are two main types of 180-degree elbows:● Long Radius (LR) 180-Degree Elbow: This elbow has a centerline radius that is approximately 1.5 times the pipe diameter, allowing for a more gradual turn and reducing turbulence.

● Short Radius (SR) 180-Degree Elbow: With a centerline radius equal to the pipe diameter, these elbows are more compact but can cause higher turbulence and pressure drop due to the sharper turn.

Specifications

● Sizes: Typically available from 1/2" to 48" (15 NB to 1200NB).

● Schedule: Options include Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS.

● Type: ERW (Electric Resistance Welded), Fabricated, Seamless, Welded.180-degree elbows are typically made from materials such as stainless steel (including 316 and 316L grades known for their corrosion resistance), carbon steel, alloy steel, and other special alloys. They meet international standards like ASTM A403, ASME SA403, and ANSI B16.9, ensuring consistent quality and performance.

Applications

● Heating and cooling systems (e.g., heat exchangers).

● Industrial processes requiring flow redirection.

● Used in pump configurations to avoid long piping loops.

180-degree elbows are essential components in many industries, ensuring efficient and reliable fluid flow in complex piping systems where a complete reversal of direction is required.

Selection Considerations

Flow Requirements: Long-radius elbows reduce friction and pressure loss.Space Constraints: Short-radius elbows fit tight spaces but increase turbulence.

Pressure & Temperature: Material and weld quality must match system demands.

Conclusion

Pipe elbows are crucial for efficient piping system design, with 45°, 90°, and 180° being the most widely used angles. The choice depends on the required flow direction, space availability, and system pressure conditions.

Pipe Elbows

Subcategory

Keyword

- Details

-

Pipe elbows are essential pipe fittings used to change the direction of flow in a piping system. They are commonly used in plumbing, HVAC, industrial pipelines, and other fluid transport systems to navigate around obstacles or follow specific layout requirements. Elbows are available in various angles, with 45°, 90°, and 180° being the most common configurations.

Key Features Of Pipe Elbows

Material:

Typically made from metals (stainless steel, carbon steel, copper, brass) or plastics (PVC, CPVC, HDPE).Connection Types:

Threaded (Screwed) – Used for small-diameter pipes.

Socket Weld – Provides a strong, leak-proof joint.

Butt Weld – Common in high-pressure systems.

Flanged – Used for easy assembly and disassembly.

Radius Types:

Short Radius (SR) – Compact, used in tight spaces.

Long Radius (LR) – Smoother flow, less pressure drop.

Common Angle Classifications

One:45-Degree Elbow

A 45-degree elbow is a type of pipe fitting designed to change the direction of fluid flow in a piping system by 45 degrees. This fitting is essential for creating a smoother transition in the pipeline, minimizing turbulence and pressure loss compared to sharper bends like the 90-degree elbow.

Types Of 45-Degree Elbows

● Long Radius (LR) 45-Degree Elbow: The radius of this elbow is 1.5 times the diameter of the pipe. It provides a gentler bend, which helps to reduce friction and maintain a steady flow, making it ideal for high-pressure and high-flow applications.

● Short Radius (SR) 45-Degree Elbow: The radius is equal to the diameter of the pipe. This type is suitable for tight spaces and low-pressure applications but may increase turbulence and pressure drop due to the sharper bend.

Specifications

Key specifications for 45-degree elbows include:● Sizes: Typically range from 1/2" to 48".

● Pressure Ratings: Generally up to 9000 psi, depending on the material.

● Materials: Commonly made from carbon steel, stainless steel, and alloy steel.

● Wall Thickness: Available in various schedules, including SCH 10, SCH 40, and SCH 80.

These specifications make 45-degree elbows a versatile choice for efficient fluid redirection in diverse piping systemsApplications

45-degree elbows are widely used in various industries, including:● HVAC Systems: They help maintain consistent airflow with minimal resistance, enhancing energy efficiency.

● Water Supply Lines: These fittings support gentle redirection of water flow, crucial for maintaining steady pressure.

● Chemical Processing: In chemical plants, 45-degree elbows ensure stable flow of sensitive materials, preventing blockages and maintaining system integrity.

● Oil and Gas: They facilitate fluid movement in complex pipeline networks, ensuring efficient transport of crude oil and natural gas.

● Food and Beverage: Used in sanitary applications to direct food-grade liquids while maintaining hygiene standards.

Two:90-Degree Elbow

A 90-degree elbow, also known as a 90-degree bend or simply an elbow, is a critical pipe fitting used in piping systems to change the direction of fluid flow by 90 degrees. Here's a detailed introduction to 90-degree elbows:

Types Of 90-Degree Elbows

● Standard 90-Degree Elbow: This is the most common type, providing a sharp 90-degree turn in the pipe. It is available in both long radius and short radius versions, with the long radius being more forgiving in terms of flow characteristics.

● Long Radius 90-Degree Elbow: This elbow has a centerline radius that is approximately 1.5 times the pipe diameter. It is preferred in applications where minimizing pressure drop and flow disturbance is crucial.

● Short Radius 90-Degree Elbow: With a centerline radius equal to the pipe diameter, these elbows are more compact but can cause higher turbulence and pressure drop due to the sharper turn.

● Offset 90-Degree Elbow: Also known as an eccentric reducer elbow, it combines the function of a 90-degree turn with a size reduction, useful for space-limited applications.

● Swept 90-Degree Elbow: This type has a more gradual curve, which helps in reducing stress concentration and vibration in the piping system.

Specifications

● Sizes: Available in a wide range of sizes from 1/2" to 72" and larger, depending on the application.

● Materials: Can be made from various materials such as carbon steel, stainless steel, brass, bronze, copper, and plastic, depending on the corrosiveness of the fluid and the temperature and pressure conditions.

● Standards: Manufactured to meet international standards such as ASME/ANSI B16.9, B16.28, BS 3799, and DIN 2605.

● Pressure Ratings: Vary based on the material and the pipe schedule, with ratings from 150 psi to 2500 psi or higher for some materials.

● End Connections: Can be threaded, socket-weld, butt-weld, or flanged, depending on the system requirements and the type of fluid being handled.

Applications

90-degree elbows are used in a wide range of applications due to their ability to make sharp turns in piping systems:● Plumbing: In residential and commercial buildings for water supply, drainage, and gas lines.

● HVAC Systems: For directing air flow in heating, ventilation, and air conditioning systems.

● Industrial Processes: In chemical, petrochemical, and pharmaceutical industries for fluid transfer and process control.

● Power Generation: Used in steam and cooling water systems in power plants.

● Marine: For fuel, water, and waste management systems on ships and offshore platforms.

90-degree elbows are essential for creating right-angle turns in piping systems, and their selection should be based on the specific needs of the application, including the type of fluid, pressure, temperature, and space constraints.

Three:180-Degree Elbow

A 180-degree elbow, also known as a "return bend" or "hairpin bend," is a type of pipe fitting used to reverse the direction of fluid flow in a piping system by a full 180 degrees.They are especially useful in applications where space is limited and a compact design is necessary, such as in wastewater treatment plants, chemical plants, and power generation facilities where pipelines need to make a sharp turn.

Types Of 180-Degree Elbows

There are two main types of 180-degree elbows:● Long Radius (LR) 180-Degree Elbow: This elbow has a centerline radius that is approximately 1.5 times the pipe diameter, allowing for a more gradual turn and reducing turbulence.

● Short Radius (SR) 180-Degree Elbow: With a centerline radius equal to the pipe diameter, these elbows are more compact but can cause higher turbulence and pressure drop due to the sharper turn.

Specifications

● Sizes: Typically available from 1/2" to 48" (15 NB to 1200NB).

● Schedule: Options include Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS.

● Type: ERW (Electric Resistance Welded), Fabricated, Seamless, Welded.180-degree elbows are typically made from materials such as stainless steel (including 316 and 316L grades known for their corrosion resistance), carbon steel, alloy steel, and other special alloys. They meet international standards like ASTM A403, ASME SA403, and ANSI B16.9, ensuring consistent quality and performance.

Applications

● Heating and cooling systems (e.g., heat exchangers).

● Industrial processes requiring flow redirection.

● Used in pump configurations to avoid long piping loops.

180-degree elbows are essential components in many industries, ensuring efficient and reliable fluid flow in complex piping systems where a complete reversal of direction is required.

Selection Considerations

Flow Requirements: Long-radius elbows reduce friction and pressure loss.Space Constraints: Short-radius elbows fit tight spaces but increase turbulence.

Pressure & Temperature: Material and weld quality must match system demands.

Conclusion

Pipe elbows are crucial for efficient piping system design, with 45°, 90°, and 180° being the most widely used angles. The choice depends on the required flow direction, space availability, and system pressure conditions.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn