- Details

-

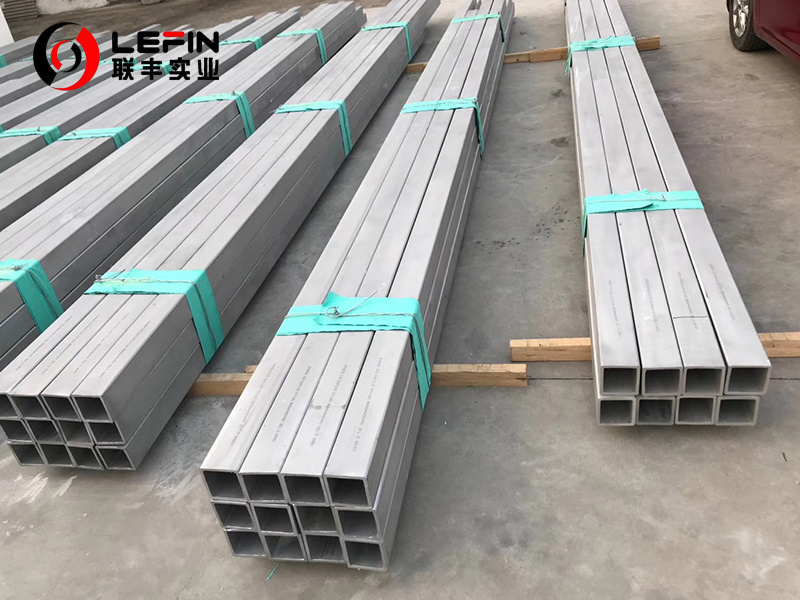

Stainless Hollow Section is a kind of high-performance structural material widely used in construction, machinery, chemical and other fields, mainly made of stainless steel, with a hollow cross-section.

Structure type and definition

Stainless steel hollow profiles can be divided into the following categories according to the section shape:

• Square Tube: square section, often used in architectural frames, decorative structures, etc.

• Round Tube: circular section, suitable for fluid transport, mechanical shaft parts, etc.

• Rectangular Tube: rectangular section, mostly used for load-bearing structures and industrial equipment.

• Seamless Tube: continuous hollow profiles without welds, suitable for high pressure or high precision scenarios (such as heat exchanger pipes).

• Custom Tube: non-standard cross sections customized according to demand, such as ellipses, hexagons, etc.Production process

The manufacturing process of stainless steel hollow profiles is mainly divided into two categories:

• Welding molding: Through the cold-rolled or hot-rolled stainless steel plate after crimping welding into a tube, low cost, suitable for common use.

• Seamless forming: Using hot piercing or cold drawing technology to avoid weld defects, suitable for high pressure or corrosion resistant environments (such as chemical pipelines).

• Surface treatment: including polishing, sandblasting, acid etching, etc., to meet the aesthetic or functional needs of different scenes.Material properties and advantages

The core advantage of stainless steel hollow profiles lies in their material characteristics:

• Corrosion resistance: Austenitic stainless steel (such as 304, 316L) performs well in wet, acid and alkali environments and is suitable for Marine engineering and chemical plants.

• High strength and lightweight: Hollow structures have higher bending and torsional properties than solid materials under the same weight, suitable for long-span buildings and Bridges.

• Hygiene: The surface is smooth and non-porous, which meets the cleanliness standards of the food and pharmaceutical industry (such as thin-walled drinking water pipes).

• High temperature resistance: Partially duplex stainless steel is stable at high temperatures for boilers and heat exchangers.Application field

Stainless steel hollow profiles are widely used in the following fields because of their comprehensive properties:

• Buildings and Bridges: such as unit curtain wall support structures, ultra-thin bridge cantilevers (case: stainless steel trusses used in Tintagel Castle Bridge, UK).

• Mechanical manufacturing: As a hydraulic system pipeline, robot skeleton, etc., need to withstand high loads and dynamic stresses.

• Energy and chemicals: heat exchange tubes, reaction vessel linings, etc., depend on corrosion resistance and high temperature resistance.

• Medical and food: Sanitary stainless steel tubes are used to transport sterile fluids or food ingredients.

• Environmental engineering: large-diameter sewage pipes and seawater desalination systems, resistant to corrosive media.

International General export standards

1. ASTM A511/A511M-21a

• Scope of application: seamless stainless steel mechanical pipe and hollow bar, suitable for high temperature, corrosion resistance scenarios (such as chemical equipment, mechanical parts).

• Core requirements:

• The grade of the material must meet the chemical composition requirements in Table 1-3 (such as 304, 316L, etc.);

• Outer diameter ≤325mm, shape including round, square, rectangular and special custom profile;

• Optional supplementary requirements (such as non-destructive testing, flaring tests, etc.) shall be specified in the contract.2. BS/EN series standards

• BS 4-2:1969: Structural performance requirements for hot rolled hollow profiles;

• BS 6633:1983: Technical specification for welded cold formed hollow steel structures;

• EN 10219: European standard for cold formed welded hollow profiles, covering dimensional tolerances and mechanical properties.3. AS 1163 (Australian Standard)

• Suitable for structural steel hollow profiles, requiring material strength, ductility and welding process to meet building load-bearing requirements.Routine test items

1. Material performance test

• Chemical composition analysis: verify the content of Cr, Ni, Mo and other elements (such as SUS304 to meet Cr 17-19%, Ni 8-11%);

• Mechanical properties test: including tensile strength, yield strength, elongation (such as elongation ≥40% as required by ASTM);

• Hardness test: Vickers hardness (HV≥200) or Rockwell hardness (HRB≥90).2. Size and surface inspection

• Section size deviation: according to the tolerance table (such as length ±1.0mm, wall thickness ±0.1mm);

• Surface quality: visual inspection of cracks, bubbles, scratches, polishing surface roughness ≤Ra 0.8μm;

• Weld inspection: X-ray or ultrasonic inspection to ensure no open welding, dislocation defects.3. Functional testing

• Corrosion resistance: salt spray test ≥500 hours (as required by JG/T 115-2018);

• High temperature resistance: high temperature stability test (suitable for duplex stainless steel);

Residual stress analysis: Evaluation of machining stress by X-ray diffraction.4. Additional tests in special scenarios

• Hygienic testing: FDA or ISO 2037 standards (surface cleanliness, no porosity) for food/medical applications;

• Fire resistance: Fire resistance test of fire resistant coating (such as BS 476 standard).

STAINLESS HOLLOW SECTION

Subcategory

Keyword

- Details

-

Stainless Hollow Section is a kind of high-performance structural material widely used in construction, machinery, chemical and other fields, mainly made of stainless steel, with a hollow cross-section.

Structure type and definition

Stainless steel hollow profiles can be divided into the following categories according to the section shape:

• Square Tube: square section, often used in architectural frames, decorative structures, etc.

• Round Tube: circular section, suitable for fluid transport, mechanical shaft parts, etc.

• Rectangular Tube: rectangular section, mostly used for load-bearing structures and industrial equipment.

• Seamless Tube: continuous hollow profiles without welds, suitable for high pressure or high precision scenarios (such as heat exchanger pipes).

• Custom Tube: non-standard cross sections customized according to demand, such as ellipses, hexagons, etc.Production process

The manufacturing process of stainless steel hollow profiles is mainly divided into two categories:

• Welding molding: Through the cold-rolled or hot-rolled stainless steel plate after crimping welding into a tube, low cost, suitable for common use.

• Seamless forming: Using hot piercing or cold drawing technology to avoid weld defects, suitable for high pressure or corrosion resistant environments (such as chemical pipelines).

• Surface treatment: including polishing, sandblasting, acid etching, etc., to meet the aesthetic or functional needs of different scenes.Material properties and advantages

The core advantage of stainless steel hollow profiles lies in their material characteristics:

• Corrosion resistance: Austenitic stainless steel (such as 304, 316L) performs well in wet, acid and alkali environments and is suitable for Marine engineering and chemical plants.

• High strength and lightweight: Hollow structures have higher bending and torsional properties than solid materials under the same weight, suitable for long-span buildings and Bridges.

• Hygiene: The surface is smooth and non-porous, which meets the cleanliness standards of the food and pharmaceutical industry (such as thin-walled drinking water pipes).

• High temperature resistance: Partially duplex stainless steel is stable at high temperatures for boilers and heat exchangers.Application field

Stainless steel hollow profiles are widely used in the following fields because of their comprehensive properties:

• Buildings and Bridges: such as unit curtain wall support structures, ultra-thin bridge cantilevers (case: stainless steel trusses used in Tintagel Castle Bridge, UK).

• Mechanical manufacturing: As a hydraulic system pipeline, robot skeleton, etc., need to withstand high loads and dynamic stresses.

• Energy and chemicals: heat exchange tubes, reaction vessel linings, etc., depend on corrosion resistance and high temperature resistance.

• Medical and food: Sanitary stainless steel tubes are used to transport sterile fluids or food ingredients.

• Environmental engineering: large-diameter sewage pipes and seawater desalination systems, resistant to corrosive media.

International General export standards

1. ASTM A511/A511M-21a

• Scope of application: seamless stainless steel mechanical pipe and hollow bar, suitable for high temperature, corrosion resistance scenarios (such as chemical equipment, mechanical parts).

• Core requirements:

• The grade of the material must meet the chemical composition requirements in Table 1-3 (such as 304, 316L, etc.);

• Outer diameter ≤325mm, shape including round, square, rectangular and special custom profile;

• Optional supplementary requirements (such as non-destructive testing, flaring tests, etc.) shall be specified in the contract.2. BS/EN series standards

• BS 4-2:1969: Structural performance requirements for hot rolled hollow profiles;

• BS 6633:1983: Technical specification for welded cold formed hollow steel structures;

• EN 10219: European standard for cold formed welded hollow profiles, covering dimensional tolerances and mechanical properties.3. AS 1163 (Australian Standard)

• Suitable for structural steel hollow profiles, requiring material strength, ductility and welding process to meet building load-bearing requirements.Routine test items

1. Material performance test

• Chemical composition analysis: verify the content of Cr, Ni, Mo and other elements (such as SUS304 to meet Cr 17-19%, Ni 8-11%);

• Mechanical properties test: including tensile strength, yield strength, elongation (such as elongation ≥40% as required by ASTM);

• Hardness test: Vickers hardness (HV≥200) or Rockwell hardness (HRB≥90).2. Size and surface inspection

• Section size deviation: according to the tolerance table (such as length ±1.0mm, wall thickness ±0.1mm);

• Surface quality: visual inspection of cracks, bubbles, scratches, polishing surface roughness ≤Ra 0.8μm;

• Weld inspection: X-ray or ultrasonic inspection to ensure no open welding, dislocation defects.3. Functional testing

• Corrosion resistance: salt spray test ≥500 hours (as required by JG/T 115-2018);

• High temperature resistance: high temperature stability test (suitable for duplex stainless steel);

Residual stress analysis: Evaluation of machining stress by X-ray diffraction.4. Additional tests in special scenarios

• Hygienic testing: FDA or ISO 2037 standards (surface cleanliness, no porosity) for food/medical applications;

• Fire resistance: Fire resistance test of fire resistant coating (such as BS 476 standard).

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn