- Details

-

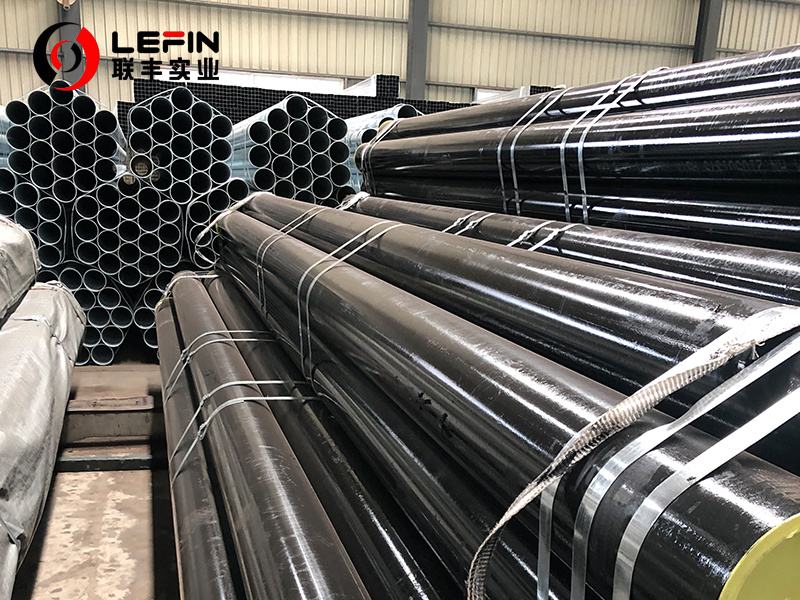

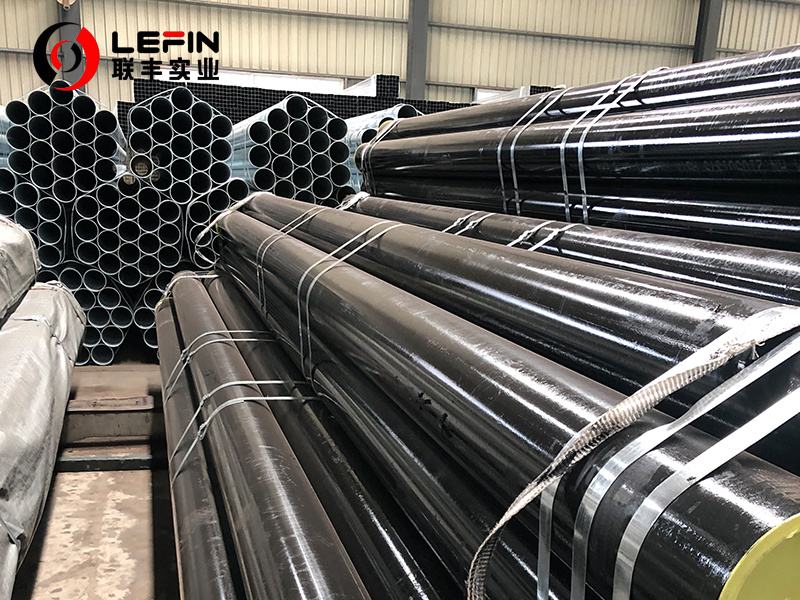

API 5L is a specification developed by the American Petroleum Institute (API) that covers seamless and welded steel line pipes used for transporting oil, gas, and water in the petroleum and natural gas industries. The specification defines two product specification levels: PSL1 (Product Specification Level 1) and PSL2 (Product Specification Level 2).

API 5L PSL1

General Description:

PSL1 is the basic grade of line pipe, designed for standard applications with lower pressure and lower risk.It is widely used in less demanding environments where high strength and toughness are not critical.

Key Features:

Chemical Composition: PSL1 has standard chemical composition requirements, focusing on basic strength and weldability. Less stringent requirements compared to PSL2.Mechanical Properties: Focuses on tensile strength and yield strength, but does not require impact toughness testing.

Non-Destructive Testing (NDT): NDT is not mandatory unless specified by the purchaser. If required, it typically includes hydrostatic testing.

Cost: More economical due to lower manufacturing and testing requirements.

Applications:

Low-pressure oil and gas pipelines.Water injection lines.

Urban gas distribution networks.

API 5L PSL2

General Description:

PSL2 is a higher-grade line pipe designed for more demanding applications, particularly in high-pressure, low-temperature, or high-risk environments.It offers enhanced safety, reliability, and performance compared to PSL1.

Key Features:

Chemical Composition: Stricter control over chemical composition, including limits on carbon equivalent (CE) for improved weldability.Mechanical Properties: Higher requirements for tensile strength, yield strength, and hardness.

Impact Toughness: Mandatory Charpy V-notch impact testing to ensure resistance to brittle fracture, especially in low-temperature environments.

Non-Destructive Testing (NDT): PSL2 requires extensive NDT, including ultrasonic testing (UT) for the pipe body and either UT or radiography for the weld seam in welded pipes.

Cost: More expensive due to stricter manufacturing and testing requirements.

Applications:

High-pressure oil and gas transmission pipelines.Long-distance pipelines.

Pipelines in cold climates (e.g., Arctic regions).

Offshore and subsea pipelines.

Critical infrastructure where safety and reliability are paramount.

General-purpose pipelines where high performance is not a priority.

Key Differences Between PSL1 and PSL2

Feature

API 5L PSL1

API 5L PSL2

Application General-purpose pipelines Critical applications: offshore, deepwater, high-pressure pipelines Chemical Composition Less strict Stricter limits on C, P, S for improved weldability & toughness Mechanical Properties Yield and tensile strength required Yield, tensile strength, and impact resistance required Impact Testing Not required Mandatory for certain grades & thicknesses Fracture Toughness Testing Not required Required for all PSL 2 pipes Non-Destructive Testing (NDT) Not required for seamless pipes 100% NDT required Hydrostatic Test Required Required Traceability Limited traceability Full traceability from raw material to final product Certification Basic mill test reports (MTR) Detailed reports including mechanical, chemical, and impact test results Marking Requirements Standard markings Additional information like heat number, PSL level, and impact test temperature How To Choose Between PSL1 And PSL2

Choosing the right Product Specification Level depends on the specific requirements of your project. Consider the following factors:Operating Conditions: If your project involves high-pressure, high-temperature, or corrosive environments, PSL2 is recommended.

Quality and Safety: PSL2 offers enhanced reliability and performance, making it suitable for critical infrastructure projects.

Cost: PSL1 is more affordable due to its less stringent requirements, but PSL2 provides long-term benefits in demanding applications.

Which Is More Commonly Used?

PSL1 is more commonly used in general-purpose applications where cost-effectiveness is a priority, and the operating conditions are less demanding.

PSL2 is increasingly used in high-performance applications, especially in modern oil and gas projects where safety, reliability, and compliance with stringent regulations are critical.

Conclusion

Both API 5L PSL1 and PSL2 serve important roles in the oil and gas industry. PSL1 is suitable for standard applications with lower requirements, while PSL2 is designed for more demanding conditions, offering enhanced performance and safety. The choice between the two depends on the specific project requirements, environmental conditions, and regulatory standards.

API 5L Line Pipe

Subcategory

Keyword

- Details

-

API 5L is a specification developed by the American Petroleum Institute (API) that covers seamless and welded steel line pipes used for transporting oil, gas, and water in the petroleum and natural gas industries. The specification defines two product specification levels: PSL1 (Product Specification Level 1) and PSL2 (Product Specification Level 2).

API 5L PSL1

General Description:

PSL1 is the basic grade of line pipe, designed for standard applications with lower pressure and lower risk.It is widely used in less demanding environments where high strength and toughness are not critical.

Key Features:

Chemical Composition: PSL1 has standard chemical composition requirements, focusing on basic strength and weldability. Less stringent requirements compared to PSL2.Mechanical Properties: Focuses on tensile strength and yield strength, but does not require impact toughness testing.

Non-Destructive Testing (NDT): NDT is not mandatory unless specified by the purchaser. If required, it typically includes hydrostatic testing.

Cost: More economical due to lower manufacturing and testing requirements.

Applications:

Low-pressure oil and gas pipelines.Water injection lines.

Urban gas distribution networks.

API 5L PSL2

General Description:

PSL2 is a higher-grade line pipe designed for more demanding applications, particularly in high-pressure, low-temperature, or high-risk environments.It offers enhanced safety, reliability, and performance compared to PSL1.

Key Features:

Chemical Composition: Stricter control over chemical composition, including limits on carbon equivalent (CE) for improved weldability.Mechanical Properties: Higher requirements for tensile strength, yield strength, and hardness.

Impact Toughness: Mandatory Charpy V-notch impact testing to ensure resistance to brittle fracture, especially in low-temperature environments.

Non-Destructive Testing (NDT): PSL2 requires extensive NDT, including ultrasonic testing (UT) for the pipe body and either UT or radiography for the weld seam in welded pipes.

Cost: More expensive due to stricter manufacturing and testing requirements.

Applications:

High-pressure oil and gas transmission pipelines.Long-distance pipelines.

Pipelines in cold climates (e.g., Arctic regions).

Offshore and subsea pipelines.

Critical infrastructure where safety and reliability are paramount.

General-purpose pipelines where high performance is not a priority.

Key Differences Between PSL1 and PSL2

Feature

API 5L PSL1

API 5L PSL2

Application General-purpose pipelines Critical applications: offshore, deepwater, high-pressure pipelines Chemical Composition Less strict Stricter limits on C, P, S for improved weldability & toughness Mechanical Properties Yield and tensile strength required Yield, tensile strength, and impact resistance required Impact Testing Not required Mandatory for certain grades & thicknesses Fracture Toughness Testing Not required Required for all PSL 2 pipes Non-Destructive Testing (NDT) Not required for seamless pipes 100% NDT required Hydrostatic Test Required Required Traceability Limited traceability Full traceability from raw material to final product Certification Basic mill test reports (MTR) Detailed reports including mechanical, chemical, and impact test results Marking Requirements Standard markings Additional information like heat number, PSL level, and impact test temperature How To Choose Between PSL1 And PSL2

Choosing the right Product Specification Level depends on the specific requirements of your project. Consider the following factors:Operating Conditions: If your project involves high-pressure, high-temperature, or corrosive environments, PSL2 is recommended.

Quality and Safety: PSL2 offers enhanced reliability and performance, making it suitable for critical infrastructure projects.

Cost: PSL1 is more affordable due to its less stringent requirements, but PSL2 provides long-term benefits in demanding applications.

Which Is More Commonly Used?

PSL1 is more commonly used in general-purpose applications where cost-effectiveness is a priority, and the operating conditions are less demanding.

PSL2 is increasingly used in high-performance applications, especially in modern oil and gas projects where safety, reliability, and compliance with stringent regulations are critical.

Conclusion

Both API 5L PSL1 and PSL2 serve important roles in the oil and gas industry. PSL1 is suitable for standard applications with lower requirements, while PSL2 is designed for more demanding conditions, offering enhanced performance and safety. The choice between the two depends on the specific project requirements, environmental conditions, and regulatory standards.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn