- Details

-

In the AS 1163 standard, the most commonly used steel grade is C350. Below is a detailed description of this grade, including its properties, applications, and advantages:

Mechanical Properties

Yield Strength: Minimum 350 MPa.

This is the stress at which the steel begins to deform plastically. A yield strength of 350 MPa makes C350 suitable for medium-load structural applications.Tensile Strength: Minimum430 MPa.

This indicates the maximum stress the steel can withstand before breaking. The range ensures a good balance between strength and ductility.Elongation: Typically around 15–20%.

This measures the steel's ability to stretch before fracture, indicating good ductility and toughness.Chemical Composition

C350 is a carbon-manganese steel with controlled amounts of alloying elements to achieve its mechanical properties.Key elements include:

Carbon (C): Provides strength and hardness. Maximum 0.20%.

Manganese (Mn): Enhances strength and toughness. Maximum 1.60%.

Silicon (Si): Improves strength and deoxidation during manufacturing. Maximum 0.25%.

Sulfur (S) and Phosphorus (P): Kept at low levels to ensure good weldability and toughness. Both maximum 0.03%

Weldability And Formability

Weldability: C350 is highly weldable, making it suitable for fabrication into complex structures. Proper welding techniques, such as preheating and post-weld heat treatment, may be required for thicker sections to prevent cracking.Formability: The steel can be easily cut, drilled, and shaped, making it ideal for a wide range of structural applications.

Applications

C350 is widely used in various structural and engineering applications due to its balanced properties. Common uses include:Commercial Buildings: Frameworks, columns, and beams for offices, shopping centers, and warehouses.

Bridges: Medium-span bridges, trusses, and support structures.

Industrial Facilities: Frames for factories, equipment supports, and storage racks.

Infrastructure: Transmission towers, communication towers, and transportation structures.

Residential Construction: Light to medium structural components in housing projects.

Advantages

Cost-Effectiveness: C350 provides a good balance between strength and cost, making it an economical choice for many projects.Versatility: Its properties make it suitable for a wide range of applications, from light to medium structural loads.

Availability: As one of the most commonly used grades, C350 is readily available in the market, ensuring easy procurement.

Durability: The steel offers excellent resistance to wear and tear, ensuring long-term performance in structural applications.

Comparison With Other Grades

Grade Yield Strength (MPa) Tensile Strength (MPa) Typical Applications C250 250 320 Light structural work, residential buildings C350 350 430 Commercial buildings, bridges, industrial structures C450 450 500 Heavy-duty structures, mining equipment AS 1163 C250: C350 offers higher strength (350 MPa vs. 250 MPa yield strength) and greater load-bearing capacity.

AS 1163 C450: While C450 provides even higher strength (450 MPa yield strength), C350 offers better ductility and is often more cost-effective.

Conclusion

AS 1163 C350 is the most commonly used steel grade in the AS 1163 standard due to its excellent combination of strength, weldability, formability, and cost-effectiveness. It is widely applied in commercial, industrial, and infrastructure projects, making it a versatile and reliable choice for medium-load structural applications. Its availability and balanced properties ensure it remains a popular option in the construction and engineering industries.

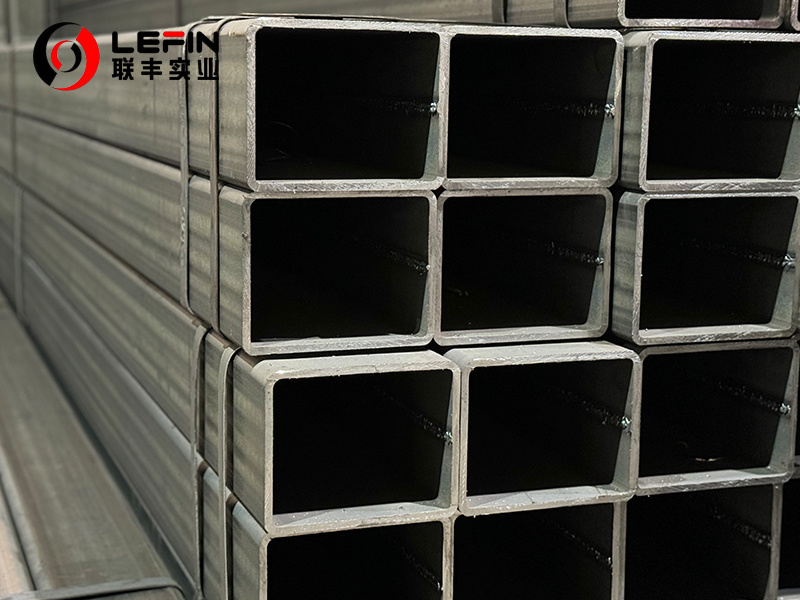

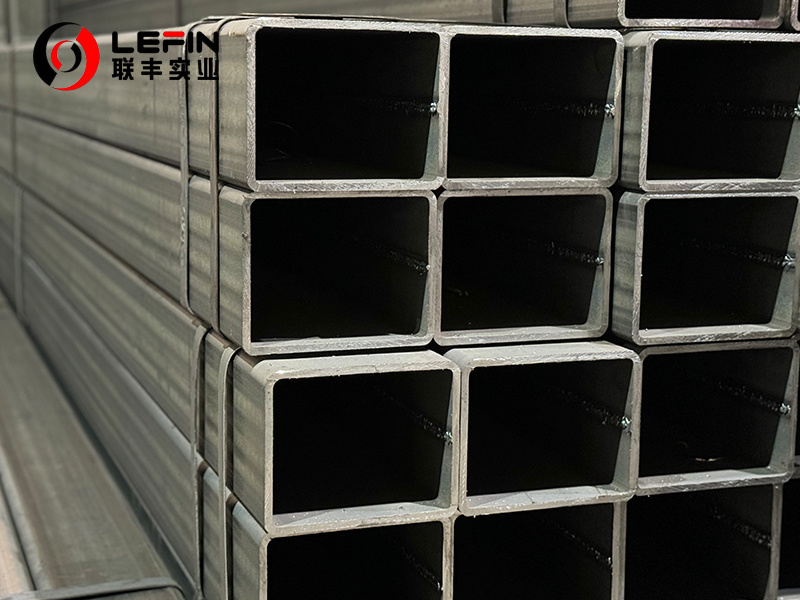

AS 1163 C350 Steel Pipes

Subcategory

Keyword

- Details

-

In the AS 1163 standard, the most commonly used steel grade is C350. Below is a detailed description of this grade, including its properties, applications, and advantages:

Mechanical Properties

Yield Strength: Minimum 350 MPa.

This is the stress at which the steel begins to deform plastically. A yield strength of 350 MPa makes C350 suitable for medium-load structural applications.Tensile Strength: Minimum430 MPa.

This indicates the maximum stress the steel can withstand before breaking. The range ensures a good balance between strength and ductility.Elongation: Typically around 15–20%.

This measures the steel's ability to stretch before fracture, indicating good ductility and toughness.Chemical Composition

C350 is a carbon-manganese steel with controlled amounts of alloying elements to achieve its mechanical properties.Key elements include:

Carbon (C): Provides strength and hardness. Maximum 0.20%.

Manganese (Mn): Enhances strength and toughness. Maximum 1.60%.

Silicon (Si): Improves strength and deoxidation during manufacturing. Maximum 0.25%.

Sulfur (S) and Phosphorus (P): Kept at low levels to ensure good weldability and toughness. Both maximum 0.03%

Weldability And Formability

Weldability: C350 is highly weldable, making it suitable for fabrication into complex structures. Proper welding techniques, such as preheating and post-weld heat treatment, may be required for thicker sections to prevent cracking.Formability: The steel can be easily cut, drilled, and shaped, making it ideal for a wide range of structural applications.

Applications

C350 is widely used in various structural and engineering applications due to its balanced properties. Common uses include:Commercial Buildings: Frameworks, columns, and beams for offices, shopping centers, and warehouses.

Bridges: Medium-span bridges, trusses, and support structures.

Industrial Facilities: Frames for factories, equipment supports, and storage racks.

Infrastructure: Transmission towers, communication towers, and transportation structures.

Residential Construction: Light to medium structural components in housing projects.

Advantages

Cost-Effectiveness: C350 provides a good balance between strength and cost, making it an economical choice for many projects.Versatility: Its properties make it suitable for a wide range of applications, from light to medium structural loads.

Availability: As one of the most commonly used grades, C350 is readily available in the market, ensuring easy procurement.

Durability: The steel offers excellent resistance to wear and tear, ensuring long-term performance in structural applications.

Comparison With Other Grades

Grade Yield Strength (MPa) Tensile Strength (MPa) Typical Applications C250 250 320 Light structural work, residential buildings C350 350 430 Commercial buildings, bridges, industrial structures C450 450 500 Heavy-duty structures, mining equipment AS 1163 C250: C350 offers higher strength (350 MPa vs. 250 MPa yield strength) and greater load-bearing capacity.

AS 1163 C450: While C450 provides even higher strength (450 MPa yield strength), C350 offers better ductility and is often more cost-effective.

Conclusion

AS 1163 C350 is the most commonly used steel grade in the AS 1163 standard due to its excellent combination of strength, weldability, formability, and cost-effectiveness. It is widely applied in commercial, industrial, and infrastructure projects, making it a versatile and reliable choice for medium-load structural applications. Its availability and balanced properties ensure it remains a popular option in the construction and engineering industries.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn