- Details

-

Basic Information

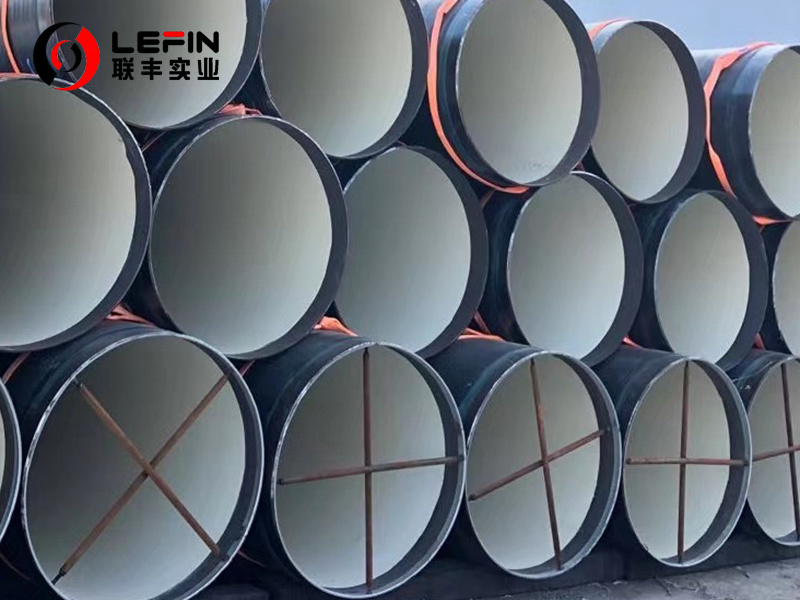

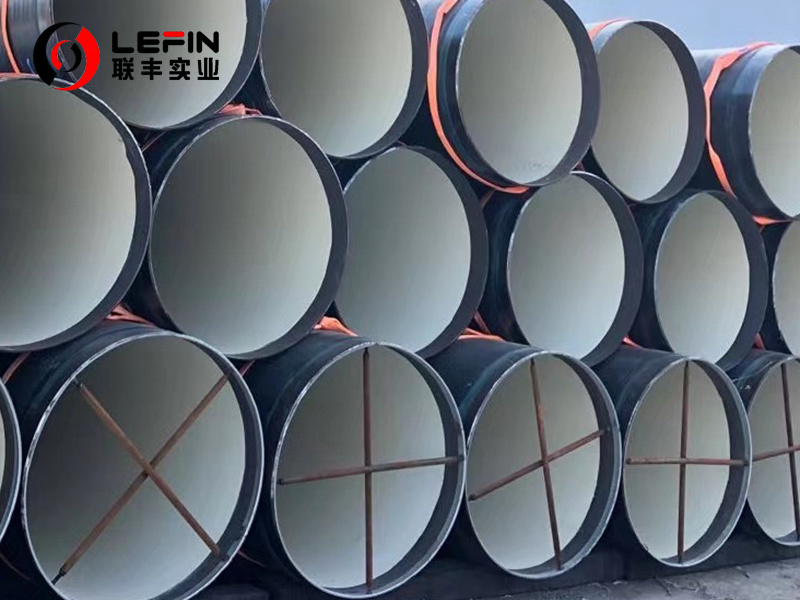

API 5L PSL1 X52 is a widely used steel grade for line pipes in the oil and gas industry due to its balanced mechanical properties, corrosion resistance, and cost-effectiveness.API 5L PSL1 X52 Line Pipe

Grades: Gr.A, Gr.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Product Specification Level: PSL1, PSL2.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12", 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Manufacturing Types: ERW, LSAW, SMLS.

Thickness Schedule: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Application: Widely used steel grade for line pipes in the oil and gas industry.

Chemical Composition

API 5L PSL1 X52 specifies the following maximum chemical element content (weight %):Element Maximum (%) Significance Carbon (C) 0.28 Affects strength and weldability. Higher carbon increases hardness but reduces ductility. Manganese (Mn) 1.40 Enhances strength and hardenability. Balances ductility and toughness. Phosphorus (P) 0.030 Impurity; reduces toughness and promotes brittleness. Sulfur (S) 0.030 Impurity; causes hot cracking during welding. Silicon (Si) 0.45 Deoxidizer; improves strength and resistance to oxidation. Note: PSL1 allows slightly higher impurity limits (e.g., Sulfur and Phosphorus) compared to PSL2, making it more cost-effective but less stringent in critical applications.

Mechanical Properties

API 5L PSL1 X52 must meet the following mechanical requirements:Property Value Range Significance Yield Strength (YS) ≥ 52,200 psi (360 MPa) Minimum strength required to resist plastic deformation under pressure. Tensile Strength (TS) ≥66,700 psi (460 MPa) Ultimate strength before failure. TS/YS ratio ensures strain capacity. Elongation ≥ 21% (for 2-inch gauge length) Measures ductility; critical for forming and bending pipes. Additional Requirements:

Hardness: Typically ≤ 248 HV10 (Vickers hardness) to avoid hydrogen-induced cracking.

Charpy Impact Test: Not mandatory for PSL1 (required for PSL2).

Applications

API 5L PSL1 X52 pipes are extensively used in the following applications:Oil and Gas Pipelines: Suitable for transporting oil, natural gas, and other fluids under high-pressure conditions.

Water Supply Systems: Used in municipal water pipelines due to their corrosion resistance.

Offshore and Onshore Projects: Ideal for both onshore and offshore applications due to their strength and durability.

Structural Applications: Used in construction and industrial projects where high strength and reliability are required.

Advantages

High Strength and Durability: X52 pipes offer sufficient strength for high-pressure applications while maintaining good ductility.Cost-Effectiveness: Compared to higher grades like X60 or X65, X52 provides a cost-effective solution without compromising on performance.

Excellent Weldability: The controlled carbon content and alloying elements ensure ease of welding, which is crucial for large-scale pipeline construction.

Corrosion Resistance: The low sulfur and phosphorus content, along with alloying elements like chromium, enhance corrosion resistance.

Versatility: Suitable for a wide range of applications, including sour service environments with additional coatings.

Comparison With Other Grades

Grade YS,min (psi) TS,min

(psi)Key Applications Advantages Over X52 Limitations vs. X52 X42 42,100 60,200 Low-pressure pipelines, water systems Lower cost, easier to weld Lower strength limits capacity X60 60,200 75,400 High-pressure gas pipelines Higher pressure handling Higher cost, stricter welding controls X65 65,300 77,600 Deepwater pipelines, Arctic conditions Superior strength for harsh environments Complex heat treatment required X70 70,300 82,700 Ultra-high-pressure gas transmission Maximizes throughput efficiency Limited availability, higher price API 5L PSL1 X52 is a versatile and cost-effective steel grade that offers a balance of strength, toughness, and corrosion resistance. Its controlled chemical composition and mechanical properties make it suitable for a wide range of applications in the oil, gas, and water transportation industries. Compared to other grades, X52 provides a reliable solution for medium to high-pressure applications without the need for more expensive materials.

API 5L PSL1 X52 Line Pipe

Subcategory

Keyword

- Details

-

Basic Information

API 5L PSL1 X52 is a widely used steel grade for line pipes in the oil and gas industry due to its balanced mechanical properties, corrosion resistance, and cost-effectiveness.API 5L PSL1 X52 Line Pipe

Grades: Gr.A, Gr.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Product Specification Level: PSL1, PSL2.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12", 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Manufacturing Types: ERW, LSAW, SMLS.

Thickness Schedule: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Application: Widely used steel grade for line pipes in the oil and gas industry.

Chemical Composition

API 5L PSL1 X52 specifies the following maximum chemical element content (weight %):Element Maximum (%) Significance Carbon (C) 0.28 Affects strength and weldability. Higher carbon increases hardness but reduces ductility. Manganese (Mn) 1.40 Enhances strength and hardenability. Balances ductility and toughness. Phosphorus (P) 0.030 Impurity; reduces toughness and promotes brittleness. Sulfur (S) 0.030 Impurity; causes hot cracking during welding. Silicon (Si) 0.45 Deoxidizer; improves strength and resistance to oxidation. Note: PSL1 allows slightly higher impurity limits (e.g., Sulfur and Phosphorus) compared to PSL2, making it more cost-effective but less stringent in critical applications.

Mechanical Properties

API 5L PSL1 X52 must meet the following mechanical requirements:Property Value Range Significance Yield Strength (YS) ≥ 52,200 psi (360 MPa) Minimum strength required to resist plastic deformation under pressure. Tensile Strength (TS) ≥66,700 psi (460 MPa) Ultimate strength before failure. TS/YS ratio ensures strain capacity. Elongation ≥ 21% (for 2-inch gauge length) Measures ductility; critical for forming and bending pipes. Additional Requirements:

Hardness: Typically ≤ 248 HV10 (Vickers hardness) to avoid hydrogen-induced cracking.

Charpy Impact Test: Not mandatory for PSL1 (required for PSL2).

Applications

API 5L PSL1 X52 pipes are extensively used in the following applications:Oil and Gas Pipelines: Suitable for transporting oil, natural gas, and other fluids under high-pressure conditions.

Water Supply Systems: Used in municipal water pipelines due to their corrosion resistance.

Offshore and Onshore Projects: Ideal for both onshore and offshore applications due to their strength and durability.

Structural Applications: Used in construction and industrial projects where high strength and reliability are required.

Advantages

High Strength and Durability: X52 pipes offer sufficient strength for high-pressure applications while maintaining good ductility.Cost-Effectiveness: Compared to higher grades like X60 or X65, X52 provides a cost-effective solution without compromising on performance.

Excellent Weldability: The controlled carbon content and alloying elements ensure ease of welding, which is crucial for large-scale pipeline construction.

Corrosion Resistance: The low sulfur and phosphorus content, along with alloying elements like chromium, enhance corrosion resistance.

Versatility: Suitable for a wide range of applications, including sour service environments with additional coatings.

Comparison With Other Grades

Grade YS,min (psi) TS,min

(psi)Key Applications Advantages Over X52 Limitations vs. X52 X42 42,100 60,200 Low-pressure pipelines, water systems Lower cost, easier to weld Lower strength limits capacity X60 60,200 75,400 High-pressure gas pipelines Higher pressure handling Higher cost, stricter welding controls X65 65,300 77,600 Deepwater pipelines, Arctic conditions Superior strength for harsh environments Complex heat treatment required X70 70,300 82,700 Ultra-high-pressure gas transmission Maximizes throughput efficiency Limited availability, higher price API 5L PSL1 X52 is a versatile and cost-effective steel grade that offers a balance of strength, toughness, and corrosion resistance. Its controlled chemical composition and mechanical properties make it suitable for a wide range of applications in the oil, gas, and water transportation industries. Compared to other grades, X52 provides a reliable solution for medium to high-pressure applications without the need for more expensive materials.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn