- Details

-

Basic Information

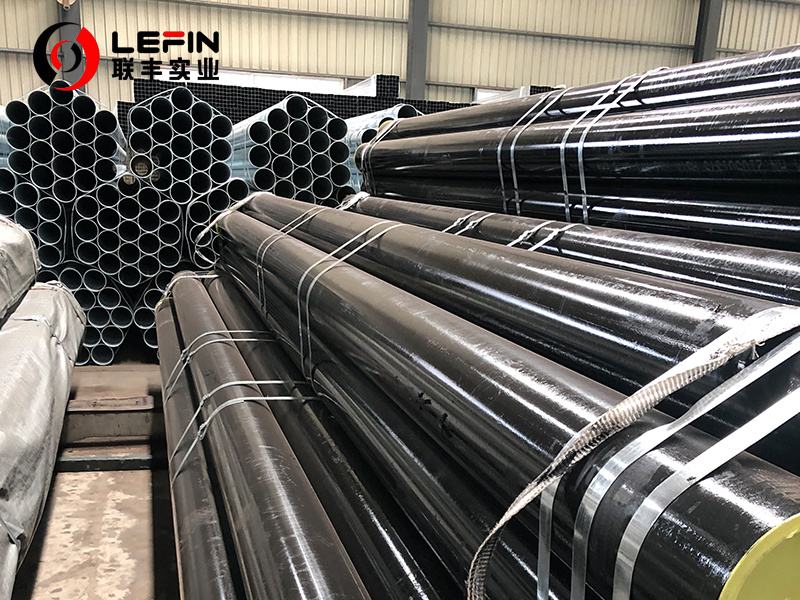

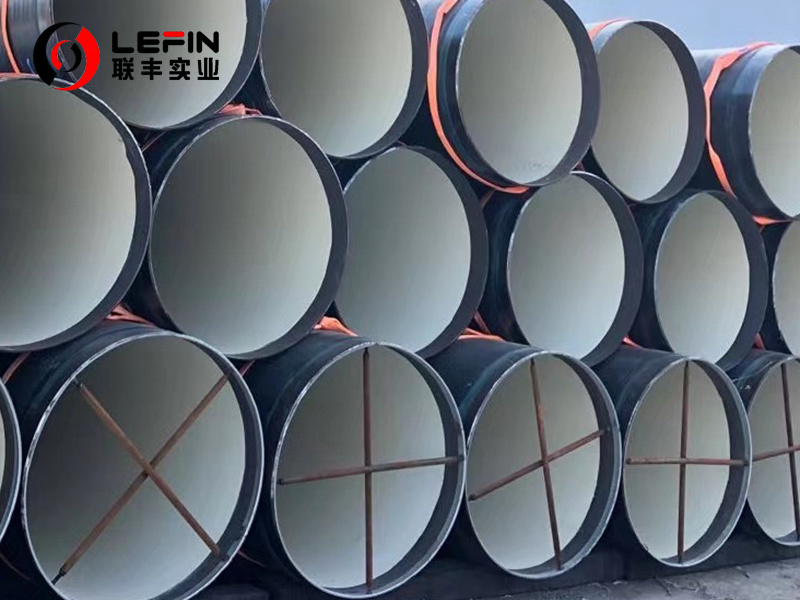

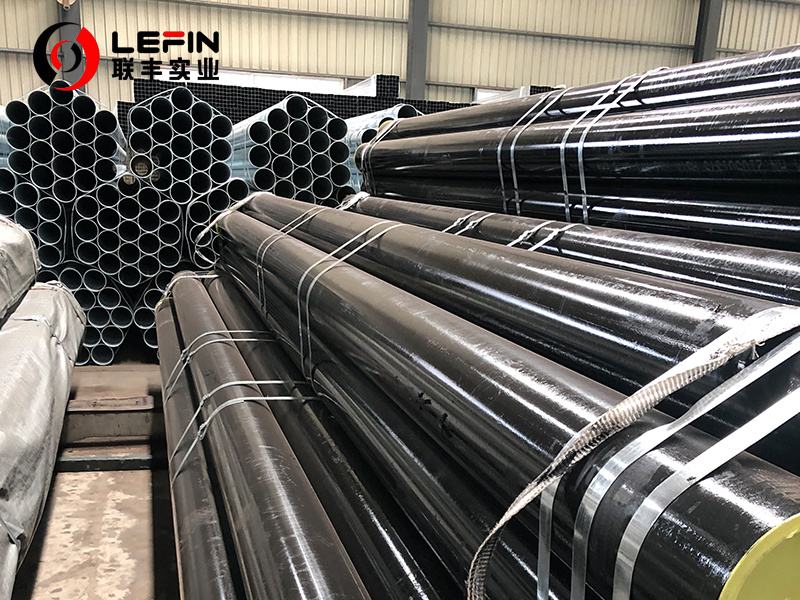

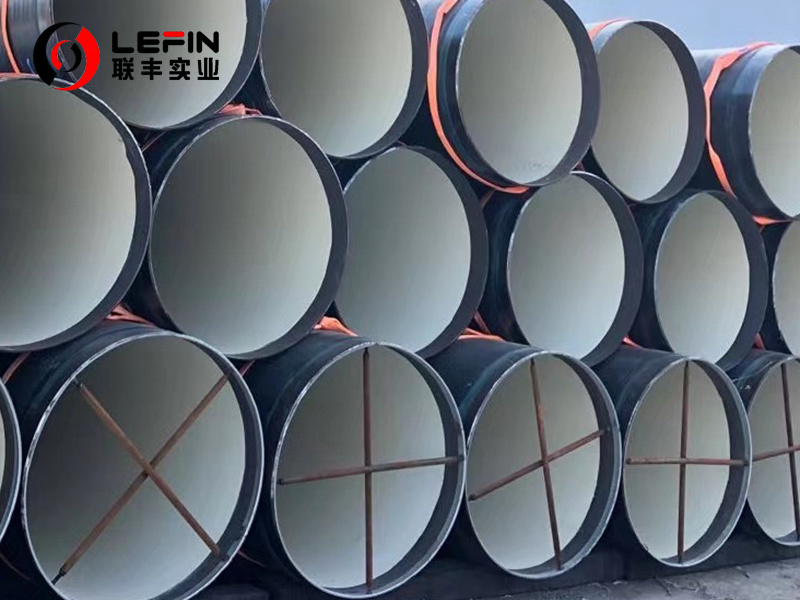

API 5L PSL2 X70 is a high-strength, low-alloy (HSLA) steel grade widely used in the oil and gas industry for pipeline applications. It is part of the API 5L specification, which governs the manufacturing, testing, and quality control of steel pipes used for transporting hydrocarbons and other fluids.API 5L PSL2 X70 Line Pipe

Grades: Gr.A, Gr.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Product Specification Level: PSL1, PSL2.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12", 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Manufacturing Types: ERW, LSAW, SMLS.

Thickness Schedule: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Application: Widely used in the oil and gas industry for pipeline.

Chemical Composition

The chemical composition of API 5L X70 PSL2 is carefully controlled to achieve its mechanical properties:Carbon (C): Maximum 0.18% for Seamless Pipe and 0.12% for Welded Pipe.

Role: Carbon is a primary strengthening element in steel. It forms iron carbides, which increase hardness and strength.

Significance: In X70, carbon content is kept relatively low to ensure good weldability and toughness. Higher carbon levels could lead to brittleness and cracking during welding.

Manganese (Mn): Maximum 1.80% for Seamless Pipeand 1.70% for Welded Pipe.Role: Manganese is a key alloying element that enhances strength, hardenability, and toughness. It also helps deoxidize the steel during production.

Significance: The high manganese content in X70 contributes significantly to its yield strength (≥70,000 psi) while maintaining ductility. It also improves the steel's ability to withstand impact loads.

Silicon (Si): Maximum 0.45% For Seamless Pipe And Welded Pipe.

Role: Silicon acts as a deoxidizer during steelmaking and enhances strength by solid solution strengthening.

Significance: It improves the steel's strength without significantly affecting its toughness or weldability. Silicon also aids in forming a protective oxide layer on the steel's surface.

Phosphorus (P): Maximum 0.025% for Seamless Pipe and Welded Pipe.Role: Phosphorus can increase strength and hardness but is generally considered an impurity in steel.

Significance: In X70, phosphorus is kept at very low levels to prevent embrittlement, which could compromise the steel's toughness and weldability.

Sulfur (S): Maximum 0.015%for Seamless Pipe and Welded Pipe.Role: Sulfur forms sulfide inclusions, which can reduce toughness and ductility.

Significance: The sulfur content in X70 is minimized to ensure high toughness and resistance to cracking, especially in low-temperature environments.

Other elements such as vanadium (V), niobium (Nb), and titanium (Ti) are controlled to ensure toughness and weldability.Mechanical Properties

API 5L X70 is designed to meet specific mechanical performance criteria:Yield Strength (YS): 70,300 - 92100 psi (485 - 635 MPa)

Ensures the pipeline can withstand high internal pressures.Tensile Strength (TS): 82,700 - 110200 psi (570 - 760 MPa)

Providing a safety margin against complete failure under extreme loads.

Toughness:

X70 steel exhibits excellent low-temperature toughness, making it suitable for harsh environments and reducing the risk of brittle fracture. This property is crucial for pipelines that may be subjected to external forces such as earthquakes or ground movements.

Applications

API 5L X70 steel is extensively used in various oil and gas applications due to its strength, toughness, and weldability:Long-Distance Pipelines:

Used for transporting oil and natural gas across challenging terrains.Offshore Pipelines:

Suitable for subsea pipelines and risers due to its ability to withstand high internal and external pressures.High-Pressure Pipelines:

Suitable for pipelines operating under high internal pressures.Arctic and Cold Climate Pipelines:

Its excellent low-temperature toughness makes it ideal for harsh environments.Gathering Lines:

Used in oil and gas fields to collect production from multiple wells and transport it to processing facilities.Liquefied Natural Gas (LNG) Facilities:

X70 steel is used in cryogenic applications for LNG storage and transportation due to its low-temperature toughness.Reasons For Popularity

Balance of Strength and Toughness:

X70 offers a good balance between high strength and low-temperature toughness, making it suitable for a wide range of applications.Weldability:

Despite its high strength, X70 maintains good weldability, which is crucial for pipeline construction and repair.Cost-Effectiveness:

Compared to higher grades like X80 or X100, X70 is more economical to produce and easier to work with in the field.Wide Availability:

X70 is widely produced and readily available, reducing lead times and supply chain risks.Proven Performance:

With decades of use in major pipeline projects worldwide, X70 has a well-established performance history, giving engineers confidence in its long-term reliability.Industry Standardization:

API 5L X70 is well-established in international standards, ensuring consistent quality and reliability.Adaptability to Modern Demands:

As energy demands grow, X70 meets the need for efficient, high-capacity pipelines capable of operating under challenging conditions.In summary, API 5L PSL2 X70 steel grade is a versatile and reliable choice for pipeline applications due to its excellent mechanical properties, weldability, and cost-effectiveness. Its widespread use in the oil and gas industry is a testament to its effectiveness and reliability.

API 5L PSL2 X70 Line Pipe

Subcategory

Keyword

- Details

-

Basic Information

API 5L PSL2 X70 is a high-strength, low-alloy (HSLA) steel grade widely used in the oil and gas industry for pipeline applications. It is part of the API 5L specification, which governs the manufacturing, testing, and quality control of steel pipes used for transporting hydrocarbons and other fluids.API 5L PSL2 X70 Line Pipe

Grades: Gr.A, Gr.B, A25, X42, X46, X52, X56, X60, X65, X70, X80M, X90M, X100M, X120M.

Product Specification Level: PSL1, PSL2.

Outer Diameter Range: 1/2" to 2", 3", 4", 6", 8", 10", 12", 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Manufacturing Types: ERW, LSAW, SMLS.

Thickness Schedule: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160.

Ends Type: Beveled ends, Plain ends.

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined.Application: Widely used in the oil and gas industry for pipeline.

Chemical Composition

The chemical composition of API 5L X70 PSL2 is carefully controlled to achieve its mechanical properties:Carbon (C): Maximum 0.18% for Seamless Pipe and 0.12% for Welded Pipe.

Role: Carbon is a primary strengthening element in steel. It forms iron carbides, which increase hardness and strength.

Significance: In X70, carbon content is kept relatively low to ensure good weldability and toughness. Higher carbon levels could lead to brittleness and cracking during welding.

Manganese (Mn): Maximum 1.80% for Seamless Pipeand 1.70% for Welded Pipe.Role: Manganese is a key alloying element that enhances strength, hardenability, and toughness. It also helps deoxidize the steel during production.

Significance: The high manganese content in X70 contributes significantly to its yield strength (≥70,000 psi) while maintaining ductility. It also improves the steel's ability to withstand impact loads.

Silicon (Si): Maximum 0.45% For Seamless Pipe And Welded Pipe.

Role: Silicon acts as a deoxidizer during steelmaking and enhances strength by solid solution strengthening.

Significance: It improves the steel's strength without significantly affecting its toughness or weldability. Silicon also aids in forming a protective oxide layer on the steel's surface.

Phosphorus (P): Maximum 0.025% for Seamless Pipe and Welded Pipe.Role: Phosphorus can increase strength and hardness but is generally considered an impurity in steel.

Significance: In X70, phosphorus is kept at very low levels to prevent embrittlement, which could compromise the steel's toughness and weldability.

Sulfur (S): Maximum 0.015%for Seamless Pipe and Welded Pipe.Role: Sulfur forms sulfide inclusions, which can reduce toughness and ductility.

Significance: The sulfur content in X70 is minimized to ensure high toughness and resistance to cracking, especially in low-temperature environments.

Other elements such as vanadium (V), niobium (Nb), and titanium (Ti) are controlled to ensure toughness and weldability.Mechanical Properties

API 5L X70 is designed to meet specific mechanical performance criteria:Yield Strength (YS): 70,300 - 92100 psi (485 - 635 MPa)

Ensures the pipeline can withstand high internal pressures.Tensile Strength (TS): 82,700 - 110200 psi (570 - 760 MPa)

Providing a safety margin against complete failure under extreme loads.

Toughness:

X70 steel exhibits excellent low-temperature toughness, making it suitable for harsh environments and reducing the risk of brittle fracture. This property is crucial for pipelines that may be subjected to external forces such as earthquakes or ground movements.

Applications

API 5L X70 steel is extensively used in various oil and gas applications due to its strength, toughness, and weldability:Long-Distance Pipelines:

Used for transporting oil and natural gas across challenging terrains.Offshore Pipelines:

Suitable for subsea pipelines and risers due to its ability to withstand high internal and external pressures.High-Pressure Pipelines:

Suitable for pipelines operating under high internal pressures.Arctic and Cold Climate Pipelines:

Its excellent low-temperature toughness makes it ideal for harsh environments.Gathering Lines:

Used in oil and gas fields to collect production from multiple wells and transport it to processing facilities.Liquefied Natural Gas (LNG) Facilities:

X70 steel is used in cryogenic applications for LNG storage and transportation due to its low-temperature toughness.Reasons For Popularity

Balance of Strength and Toughness:

X70 offers a good balance between high strength and low-temperature toughness, making it suitable for a wide range of applications.Weldability:

Despite its high strength, X70 maintains good weldability, which is crucial for pipeline construction and repair.Cost-Effectiveness:

Compared to higher grades like X80 or X100, X70 is more economical to produce and easier to work with in the field.Wide Availability:

X70 is widely produced and readily available, reducing lead times and supply chain risks.Proven Performance:

With decades of use in major pipeline projects worldwide, X70 has a well-established performance history, giving engineers confidence in its long-term reliability.Industry Standardization:

API 5L X70 is well-established in international standards, ensuring consistent quality and reliability.Adaptability to Modern Demands:

As energy demands grow, X70 meets the need for efficient, high-capacity pipelines capable of operating under challenging conditions.In summary, API 5L PSL2 X70 steel grade is a versatile and reliable choice for pipeline applications due to its excellent mechanical properties, weldability, and cost-effectiveness. Its widespread use in the oil and gas industry is a testament to its effectiveness and reliability.

Related products

Product Consulting

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn