Are There Any Requirements For Scaffolding Steel Pipes in Malaysia

Release time:

2025-10-31

The requirements for scaffolding steel pipes in Malaysia are mainly based on the national standard MS 1462-2-1:2010 "Metal Scaffolding - Part 2: Tubular (pipe and joint) Scaffolding - Section 1: Steel pipe Specifications", and a strict system has been formed in combination with safety regulations and industry practices.

I. Core Standards and Material Requirements

1.MS 1462-2-1:2010 standard

- Material:

Non-alloy structural steel (grade S235GT) is adopted, and the chemical composition must meet the requirements of carbon (C) ≤0.22%, manganese (Mn) ≤1.40%, phosphorus (P) ≤0.045%, and sulfur (S) ≤0.045%.

- Dimensions:

The outer diameter is fixed at 48.3mm , the wall thickness is commonly 3.2mm and 4.0mm (allowable deviation ±10%), and the length is usually 6 meters or customized.

- Mechanical properties:

Tensile strength ≥360 MPa, yield strength ≥235 MPa, elongation ≥25%, which must be verified through tensile tests.

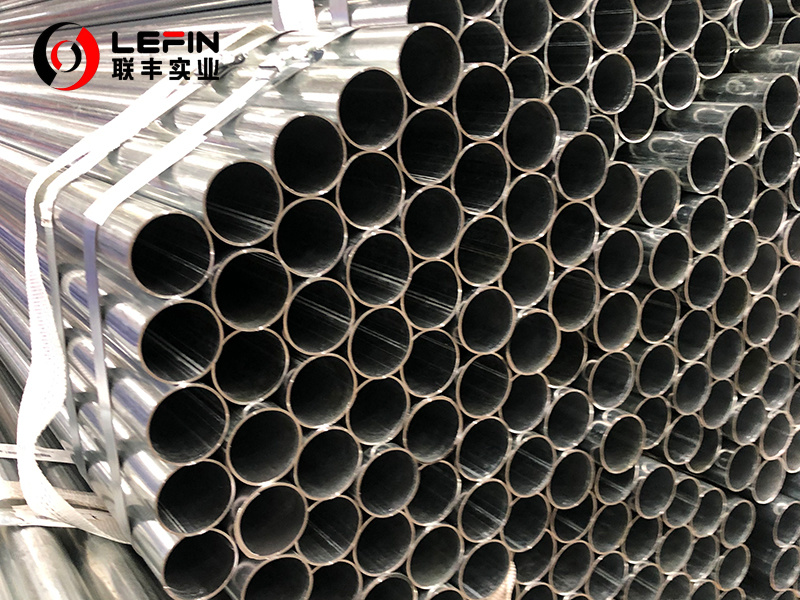

- Surface treatment:

Hot-dip galvanizing must be carried out, with a coating thickness of ≥85 μm (in compliance with EN 10240 standard) to resist outdoor corrosion.

2. Compatibility and International Standards

SSteel pipes should be used in conjunction with EN 74 standard joints (such as cross couplings, turning couplings), and often need to comply with EN 39 standard (European specification for scaffolding Steel pipes) at the same time to ensure international universality.

II. Safety Regulations and Design Requirements

1.OSHA Safety Regulations

- Design Certification : The scaffolding must be designed by a registered professional engineer and be capable of withstanding at least four times the designed load , and a detailed calculation document must be submitted for record.

- Platform and Protection:

- The width of the work platform should be no less than 450mm, the lap length of the scaffold board should be no less than 225mm, and safety railings 1.0-1.1 meters high and skirting boards should be set at the edges.

- Scaffolding over 4 meters in height must be equipped with a fall prevention system (such as safety nets, safety belt anchor points).

- Inspection System:

- Pre-use Inspection : Before each use, a certified person should conduct an inspection to ensure there is no deformation, rust or loose connection.

- Daily Inspection : Conduct daily inspections during use, keep records and preserve them for at least 3 months.

- Special Circumstances Inspection : After encountering strong winds (wind speed >38 km/h), heavy rain or accidents, safety must be re-evaluated before use.

2. Load and Stability

Overloading is strictly prohibited. The maximum allowable load (unit: kg/m²) must be clearly marked at a prominent position.

The foundation of the scaffolding must be flat and solid. Pads or bases should be set at the bottom of the vertical poles to prevent settlement.

III. Construction and Management Requirements

1. Personnel qualifications

- Installation and Dismantling :

Operated by workers holding CIDB green cards (certified by the Construction Industry Development Board), and inspected and accepted by JKKP-certified Scaffolder.

- Training Requirements :

All workers must receive scaffolding safety training, which includes fall prevention, load calculation and emergency response.

2. Documents and Identifiers

Each steel pipe shall be marked with MS 1462-2-1:2010 standard number , outer diameter, wall thickness, production batch and galvanized coating thickness.

Scaffolding should be hung with Safety warning signs , indicating the maximum load, erection date and the person responsible for inspection.

IV. Certification and Import Requirements

1. Local authentication

Steel pipes and fittings need to pass the Cream certification (Construction Research Institute of Malaysia) Obtain the Certificate of Approval (COA) or the Perakuan Pematuhan Standard (PPS) certificate.

For imported steel pipes, a third-party test report (such as SGS certification) must be provided to verify the material, size and quality of the galvanized coating.

2. Import Compliance

Must comply with MS 1462 or EN 39 standards and pass the product safety audit of the Malaysian customs.

The use of uncertified second-hand steel pipes or refurbished parts is prohibited. Violators will face a fine of RM 1,000-RM 200,000 or be ordered to suspend work for rectification.

V. Environmental Protection and Sustainability

1. Material recycling

Waste steel pipes must be recycled through channels certified by the Malaysian Steel Recycling Association (MSRA) and are strictly prohibited from being discarded at will.

2. Green Construction orientation

Encourage the use of reusable modular scaffolding to reduce material waste. In government projects, contractors who use environmentally friendly materials can enjoy tax benefits.

VI. Penalties and Supervision for Violations

1. CIDB Supervision :

The Construction and Development Board (CIDB) of Malaysia conducts regular spot checks on construction sites and imposes fines of RM 10,000-RM 500,000 on violations of standards , and may also revoke the qualifications of contractors.

2. Legal Liability :

In the event of an accident caused by scaffolding defects, the owner, contractor and engineer shall bear joint and several liability, with a maximum sentence of five years in prison .

VI. Penalties and Supervision for Violations

1. Technology Upgrade :

Starting from 2025, some large-scale projects will pilot the use of intelligent scaffolding monitoring systems (such as load sensors and tilt alarms) to monitor structural safety in real time.

2. Standard Update :

MS 1462 plans to introduce BIM modeling requirements to enhance the digital collaboration level between design and construction, but it has not been officially implemented yet.

Summary

Malaysia's requirements for scaffolding steel pipes cover the entire life cycle from material production to on-site use, emphasizing standardization, safety and sustainability. Whether it is local procurement or import, it is necessary to strictly follow the MS 1462 standard and relevant safety regulations, and at the same time pay attention to the latest technological trends to meet future compliance requirements.

Tags:

Previous

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn