difference between LSAW pipe and SSAW pipe

Release time:

2021-04-14

LSAW Pipe (Longitudinal Submerged Arc-Welding Pipe), also called SAWL pipe. It is taking the steel plate as raw material, mold it by the molding machine, then do double-sided submerged arc welding. Through this process the LSAW steel pipe will get excellent ductility, weld toughness, uniformity, plasticity and great sealing.

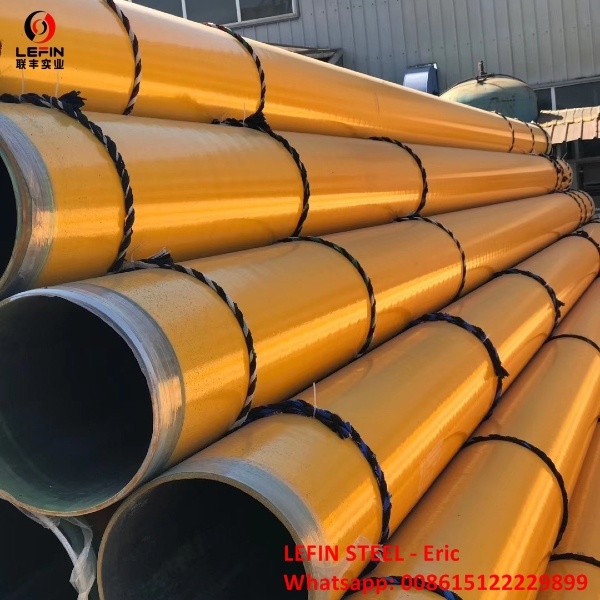

LEFIN STEEL produce large diameter pipes through SSAW and LSAW two welding ways.

LSAW Pipe (Longitudinal Submerged Arc-Welding Pipe), also called SAWL pipe. It is taking the steel plate as raw material, mold it by the molding machine, then do double-sided submerged arc welding. Through this process the LSAW steel pipe will get excellent ductility, weld toughness, uniformity, plasticity and great sealing.

The LSAW pipe diameter range is larger than ERW, normally from 16 inch to 60 inch, 406mm to 1500mm. Good performances on high pressure resistance, and low-temperature corrosion resistance.

It has been widely applied in the oil and gas pipelines, specially required large diameter and thick wall pipe with high strength and long distance. Meanwhile in construction of structure that need tough strength, water treatment, thermal industry, bridge building, etc. According API specifications, the LSAW pipe (SAWL pipe or JCOE pipe) is specially designated in large scaled oil and gas transportation, in the cases that pipelines across the city, sea, and the urban area. These are the class 1 and class 2 areas.

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also called HSAW pipe (Helical SAW), welding line shape like a helix. It is using the same welding technology of Submerged Arc-Welding with LSAW pipe. Differently SSAW pipe is spiral welded where the LSAW is longitudinally welded. Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.

The SSAW pipe diameter range is from 20 inch to 100 inch, 406 mm to 2540 mm.The advantage part is we can get the different diameter of SSAW pipes with the same size of the steel strip, there is a wide application for the raw material steel strip, and welding seam should avoid the primary stress, good performances to bear the stress.

The disadvantage is the bad physical dimension, welding seam length is longer than the pipe length, easy to cause the defects of cracks, air hole, cinder inclusion, partial welding, welding force in pulling status.

For oil and gas pipeline systems, but in petroleum design specification, the SSAW pipe / HSAW pipe could only be applied in class 3 and class 4 areas. Construction structure, water transport and sewage treatment, thermal industry, buildings etc.

LSAW pipe has better performances than SSAW pipe.

As above the specs of the both kind SAW pipe, it defined that SSAW pipe will be used in the area that not very important. Until now, United States, Japan, Germany have reject attitude for SSAW pipe, and not suggested in the key pipelines. Canada and Italy use SSAW pipe for partial pipelines. Russian few pipelines in SSAW, plus they have made strict implement terms. And for China, because of the historical factors, most of the key pipelines in China still use SSAW pipe.

Compared to seamless pipe, ERW pipe. ERW, SAW pipe is mainly used in oil and gas transportation. Where Seamless steel pipe is mainly used in oil and gas drilling, explorations.

Tags:

Previous

Relevant Project

Address: Hengtai Road,Daqiuzhuang Town,Jinghai County,Tianjin,China

Mob: +8615122229899(whatspp)

Phone: +86 22 58171905

Fax: +86 22 58171902

E-mail:info@lefinsteel.com

Get company updates

Tianjin Lefin Industrial Co.,Ltd. All rights reserved City sub-station SEO www.300.cn